Diesel engine belt pulley tensioning device

A technology of tensioning device and pulley, applied in the direction of belt/chain/gear, transmission device, mechanical equipment, etc., can solve the problems of limited application scope and complicated operation, and achieve the effect of convenient operation, good effect and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

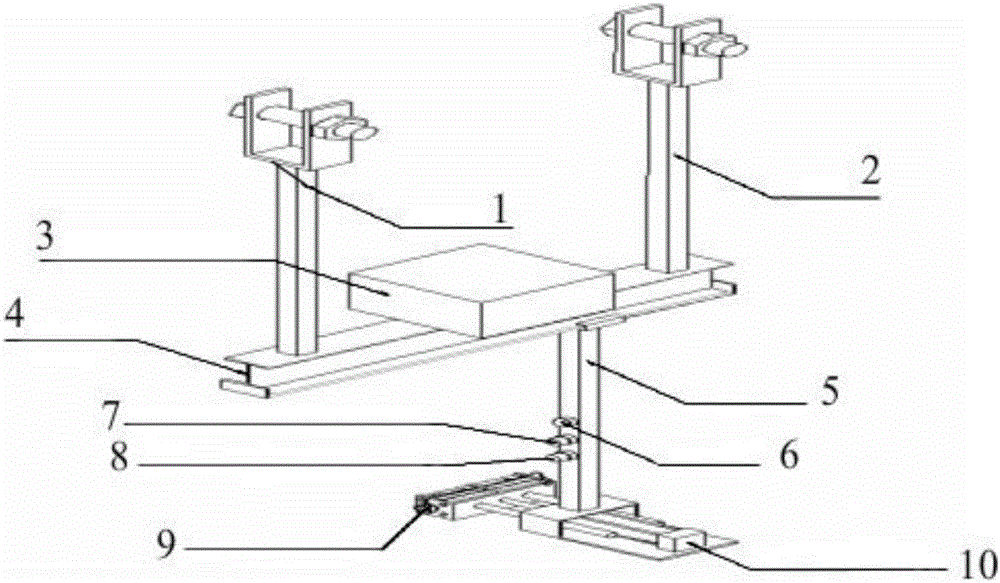

[0019] Such as figure 1 As shown, a diesel engine pulley tensioning device includes an executive component and a control system; the executive component mainly includes a frame, a single rod cylinder 10, and a double rod cylinder 9; the frame includes a column 5, a guide rail 4, Hanging column 2, the upper end of the column 5 is slidably connected with the guide rail 4 through a pulley block, so that the working cylinder can be flexibly slid during work operation. The two ends of the guide rail 4 are provided with anti-falling baffles to prevent the post 5 from falling off the guide rail 4. The upper ends of the guide rail 4 are also combined with a suspension column 2 on each side, and the upper end of the suspension column 2 is connected with a connecting bolt assembly 1, and the whole device is suspended on the work site through the connecting bolt assembly 1. The lower end of the column 5 is fixed to the cylinder barrel of the single rod cylinder 10 through an iron frame. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com