Installation structure of monitoring system

A technology of installation structure and monitoring system, applied in optics, instruments, camera bodies, etc., can solve problems such as affecting the quality of information collection or monitoring, increasing the total cost of precision instrument monitoring, consuming a lot of time and physical strength, etc. Improve the service life, effective data support, and reduce the effect of mutual wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

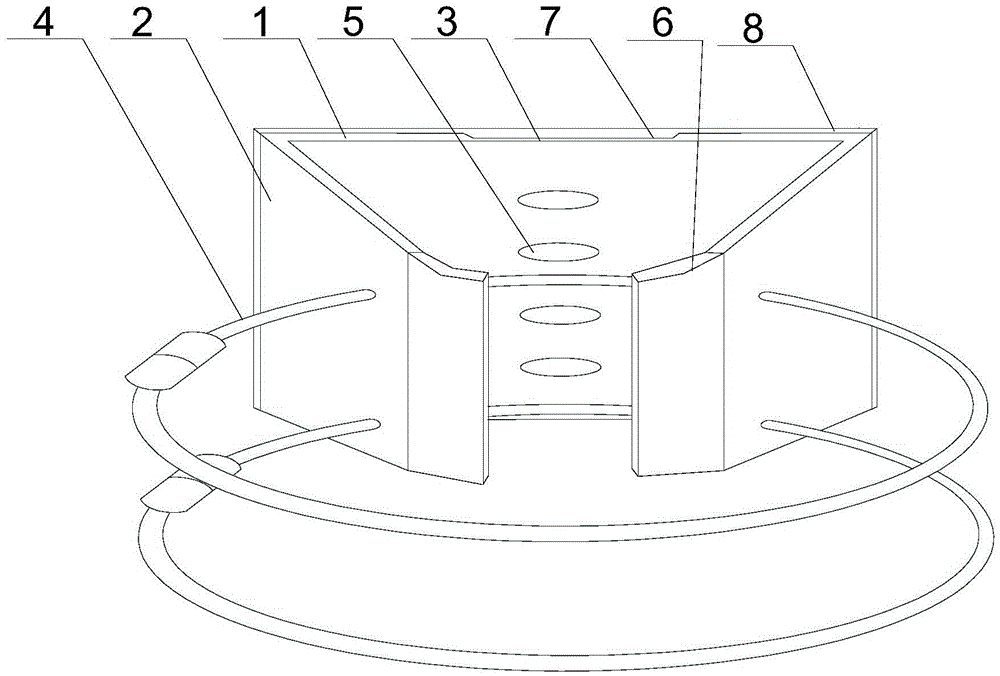

[0019] Such as figure 1 As shown, the present invention includes a dovetail-shaped mounting seat 1 composed of a bottom plate 3 and two fixing plates 2 arranged at both ends of the bottom plate 3. A plurality of screw holes 5 are opened in the middle of the bottom plate 3. The holes 5 are stacked and distributed from top to bottom, and two through holes are opened on the fixing plate 2, and the two clamps 4 respectively penetrate the two through holes corresponding to each other on the two fixing plates 2; Two elastic adjusting plates 6, both of which are arc-shaped and are respectively installed on the opposite end faces of the two fixed plates 2, a dovetail groove is opened in the middle of the back of the bottom plate, and the dovetail The width of the groove decreases from top to bottom along the plane of the bottom plate, and also includes a connecting plate. The connecting plate is provided with protrusions matching the dovetail groove. The connecting plate is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com