Placement mechanism of high-precision equipment working condition monitoring system

A monitoring system, high-precision technology, applied in the direction of mechanical equipment, supporting machines, machines/supports, etc., can solve the problems that affect the quality of information collection or monitoring, increase the total cost of precision instrument monitoring, consume a lot of time and physical strength, etc. , to achieve the effect of improving service life, effective data support, and reducing mutual wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

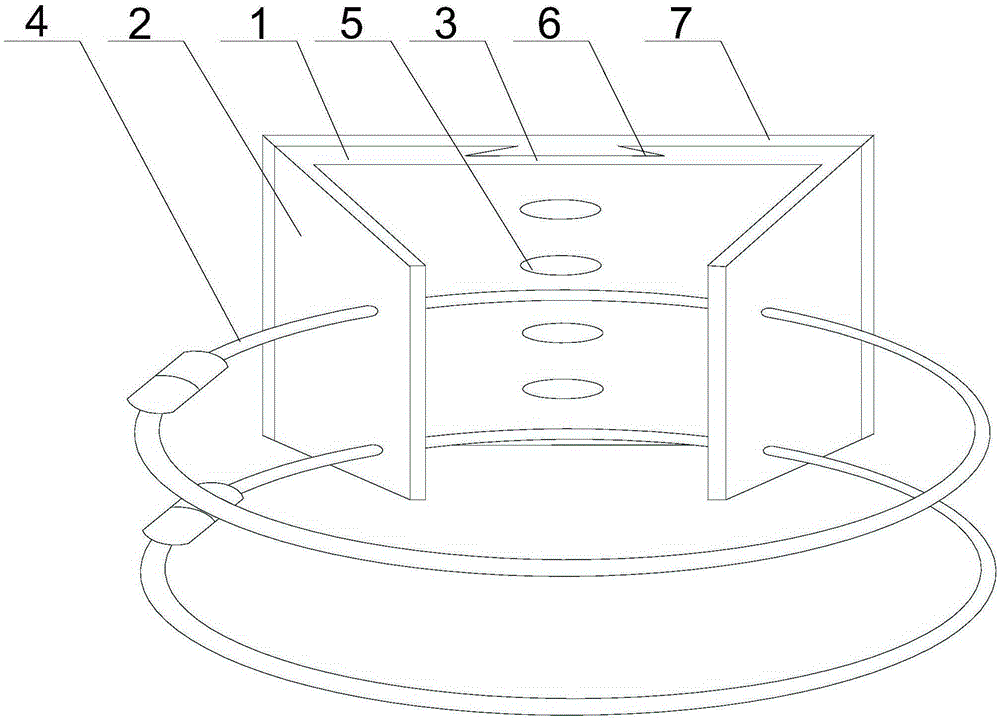

[0019] Such as figure 1 As shown, the present invention includes a dovetail-shaped mounting seat 1 composed of a base plate 3 and two fixing plates 2 arranged at two ends of the base plate 3. A plurality of screw holes 5 are provided in the middle of the base plate 3, and a plurality of the screw holes 5 are provided. The holes 5 are stacked and distributed from top to bottom, and two through holes are opened on the fixed plate 2, and the two clamps 4 respectively pass through the two through holes corresponding to each other on the two fixed plates 2. The back middle part of the bottom plate 3 is provided with a dovetail groove 6, the width of the dovetail groove 6 decreases from top to bottom along the plane of the bottom plate 3, and a connecting plate 7 is provided on the connecting plate 7, which is provided with a matching dovetail groove 6 The connecting plate 7 is provided with a plurality of mounting holes coaxial with the screw holes 5 . When the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com