Broiler breeder feeding device

A broiler breeder and walking frame technology, which is applied in application, poultry industry, animal husbandry, etc. It can solve the problems of poor uniformity of chicken flocks, failure to go up the peak of egg production, quantitative feeding, etc., and it is easy to achieve weight uniformity , reduce the emergency of feed restriction, and alleviate the effect of work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

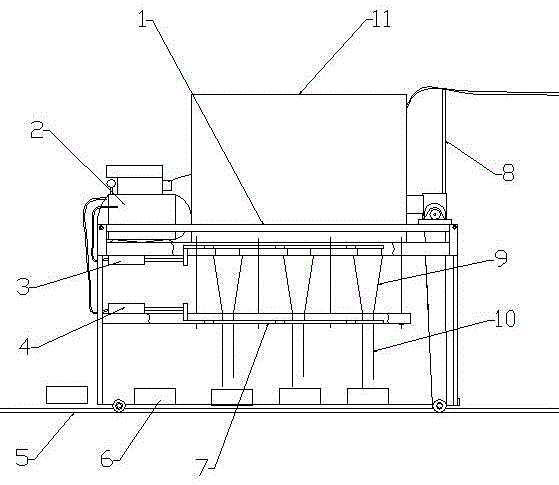

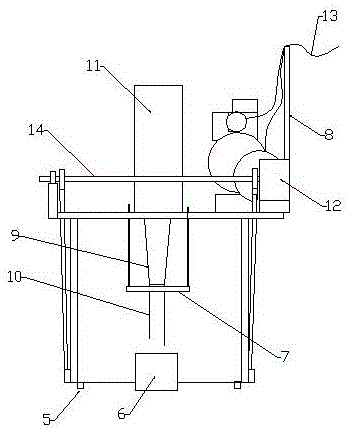

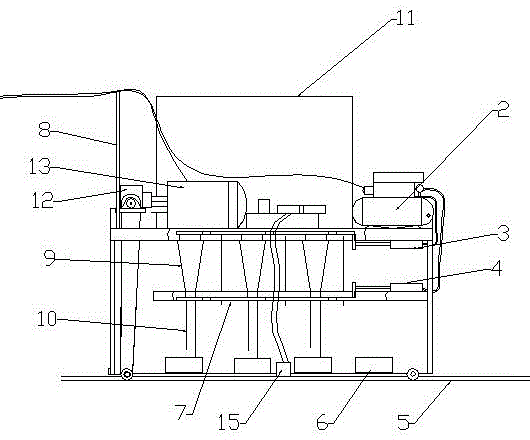

[0021] Specific implementation methods: such as figure 1 , 2 A broiler breeder feeding device shown in 3, includes a walking frame 1 and a material storage box 11 arranged on the running track 5, a feeding trough 6 is arranged between the track 5, and the material storage box 11 is arranged on the walking track 5. The upper loading plate of the frame; the middle position of the walking frame 1 is provided with a discharge plate 7, a pre-filling tube 9 is provided between the discharging plate 7 and the loading plate, and a material guide tube 10 is provided under the pre-filling tube 9 ; The loading plate is provided with a pneumatic flashboard for controlling material leakage from the storage box 11 to the pre-filling tube 9, and the discharge plate 7 is provided with a pneumatic flashing plate for releasing the feed in the pre-filling tube 9; The pneumatic gate is connected and controlled by the cylinder I3 on the loading plate; the pneumatic gate on the discharge plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com