Assembling type structure of symmetric wing type net cage floating tube frame and construction method

A symmetrical wing and assembled technology, applied in fish farming, application, climate change adaptation, etc., can solve the problem of large curvature of the front pipe section, difficult construction, difficulty in ensuring the construction accuracy of the floating pipe frame of the symmetrical airfoil cage, etc. problem, to achieve high connection precision and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

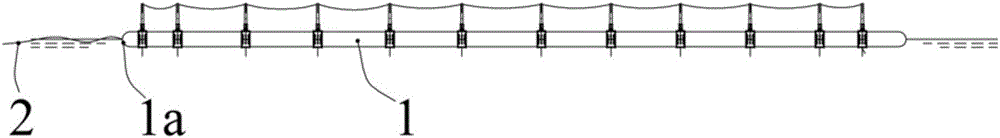

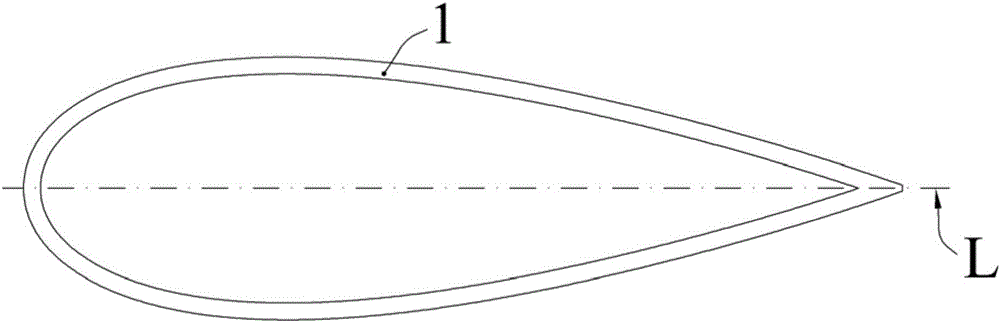

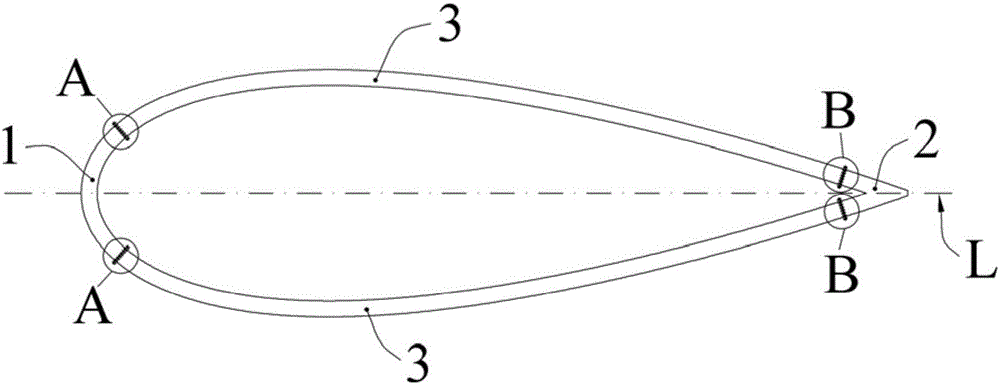

[0057] like Figure 3 to Figure 5As shown, the assembled structure of the symmetrical airfoil net cage floating tube frame of Embodiment 1 of the present invention is made up of wing tip component 1, wing tail component 2 and two wing side components 3; wherein, wing tip component 1 is provided with arc The metal pipe 11 and two metal flanges 12, the left part of the arc metal pipe 11 is symmetrical to the right part, and the inner end faces of the two metal flanges 12 are respectively connected to the left nozzle and the right part of the arc metal pipe 11 The upper and outer end faces of the nozzle are perpendicular to the axis of the arc-shaped metal pipe 11; the wing tail member 2 is provided with a V-shaped pipe 21 and two connecting flanges 22 made of the same material as the V-shaped pipe 21, and the left part of the V-shaped pipe 21 is connected to the The right part is symmetrical, and the inner end surfaces of the two connecting flanges 22 are respectively connected ...

Embodiment 2

[0070] like Image 6 and Figure 7 As shown, the assembled structure of the second embodiment of the present invention is basically the same as that of the first embodiment, and their difference is that the second embodiment of the present invention adopts the following structure:

[0071] The metal flange 12 and the connecting flange 22 are not provided with a central through hole, that is, the left nozzle and the right nozzle of the arc metal pipe 11 are closed by the metal flange 12 connected thereto, and the V-shaped pipe 21 The left nozzle and the right nozzle of the nozzle are closed by the connecting flange 22 connected thereto; the HDPE flange 32 is provided with a central through hole communicating with the inner cavity of the HDPE straight pipe 31;

[0072] The wingtip component 1 is also provided with two metal shaping tubes 13, the inner ends of the two metal shaping tubes 13 are respectively connected to the outer end surfaces of the two metal flanges 12, and the...

Embodiment 3

[0078] like Figure 8 As shown, the assembled structure of the third embodiment of the present invention is basically the same as that of the first embodiment, and their difference is that the third embodiment of the present invention adopts the following structure:

[0079] The arc-shaped metal pipe 11 is composed of a central large-diameter tube body 111, a left part variable-diameter tube body 112, a left part small-diameter tube body 113, a right part variable-diameter tube body 114, and a right part small-diameter tube body 115. The middle large-diameter tube body 111 The left port of the left port is connected to the left small-diameter pipe body 113 through the left reducing pipe body 112, and the right port is connected to the right small-diameter pipe body 115 through the right reducing pipe body 114; the outer diameter of the middle large-diameter pipe body 111 is larger than the left small-diameter pipe body The outer diameter of the pipe body 113 and the outer diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com