Green bean drying and frying method

A green bean frying technology, which is applied in the field of food processing, can solve the problems of uneven heating of green beans, low water content of green beans, and operator injury, and achieve the effects of shortening the frying cycle, increasing air pressure, and increasing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

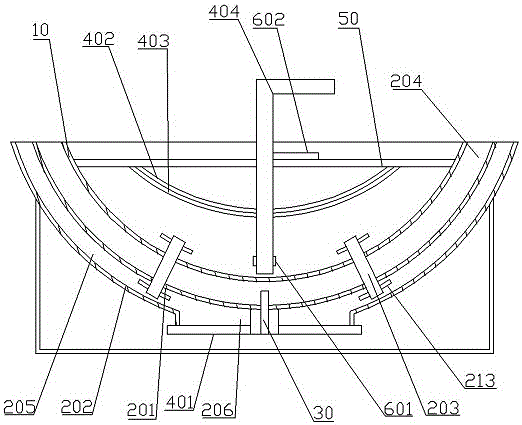

[0021] The reference signs in the drawings of the description include: pot body 10, first housing 201, second housing 202, stirring rod 203, fan blade 213, combustion chamber 204, drying chamber 205, discharge port 206, ignition valve 30. The first filter screen 401 , the second filter screen 402 , the third filter screen 403 , the rotating rod 404 , the sealing cover 50 , the temperature sensor 601 , and the temperature display 602 .

[0022] The embodiment relates to a green bean frying device basically as attached figure 1 Shown: including pot body 10, drying mechanism, frying mechanism and heating mechanism.

[0023] The drying mechanism includes a first housing 201, a second housing 202, several stirring rods 203, guide rails 204 and rollers 205, the first housing 201 and the outer surface of the pot body 10 surround a combustion chamber 206, and the first housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com