Method for producing quick-frozen bamboo shoots

A production method and technology for bamboo shoots are applied in the production field of quick-frozen bamboo shoots, and can solve the problems of affecting taste, natural flavor of bamboo shoots, and soft tissue of quick-frozen bamboo shoots, and achieve the effect of maintaining color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

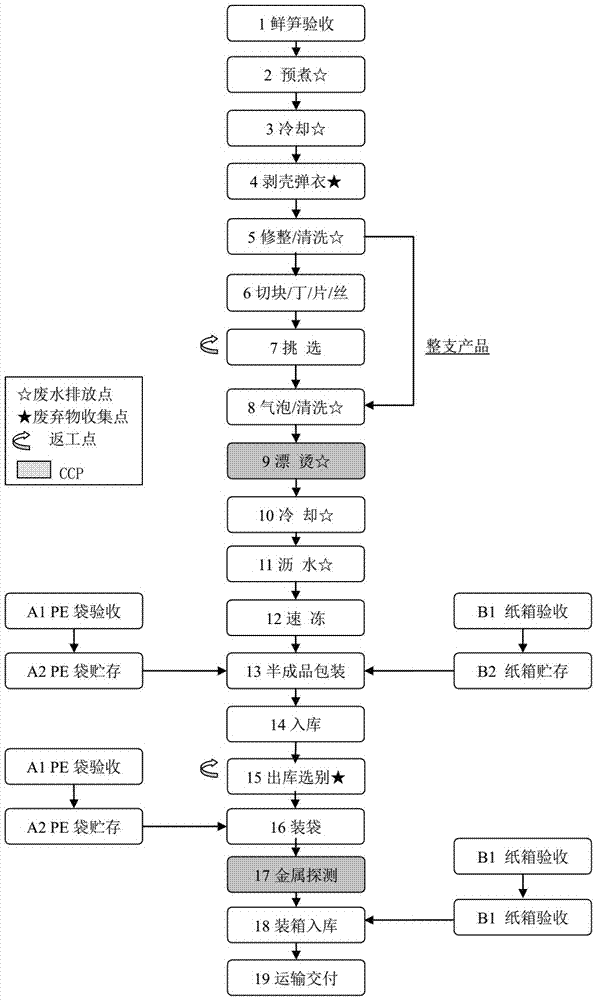

Image

Examples

Embodiment 1

[0035] A production method of quick-frozen bamboo shoots, using fresh bamboo shoots as raw material, obtaining quick-frozen bamboo shoots after precooking, cleaning, sterilizing and freezing, specifically comprising the following steps:

[0036] 1) Acceptance of fresh bamboo shoots: Fresh bamboo shoots have normal appearance, no peculiar smell, and no pesticide residues and heavy metals;

[0037] 2) Pre-cooking: put the fresh bamboo shoots in a cooking tank and boil them in boiling water for 35 minutes to prevent further lignification and ensure the crispness of the bamboo shoots;

[0038] 3) Cooling: After precooking is completed, cool to room temperature with normal temperature running water;

[0039] 4) Shelling and shelling: Manually peel off the thick and old bamboo shells, use a slingshot to remove the tender bamboo shoots and bamboo shoots, and pay attention to avoid damage to the bamboo shoots and ears;

[0040] 5) Trimming and cleaning: remove the middle and lower sk...

Embodiment 2

[0057] A production method of quick-frozen bamboo shoots, using fresh bamboo shoots as raw material, obtaining quick-frozen bamboo shoots after precooking, cleaning, sterilizing and freezing, specifically comprising the following steps:

[0058] 1) Acceptance of fresh bamboo shoots: Fresh bamboo shoots have normal appearance, no peculiar smell, and no pesticide residues and heavy metals;

[0059] 2) Pre-cooking: put the fresh bamboo shoots in a cooking tank and boil them in boiling water for 45 minutes to stop lignification and ensure the crispness of the bamboo shoots;

[0060] 3) Cooling: After precooking is completed, cool to room temperature with normal temperature running water;

[0061] 4) Shelling and shelling: Manually peel off the thick and old bamboo shells, use a slingshot to remove the tender bamboo shoots and bamboo shoots, and pay attention to avoid damage to the bamboo shoots and ears;

[0062] 5) Dressing and cleaning: remove the middle and lower skins of the ...

Embodiment 3

[0078] A production method of quick-frozen bamboo shoots, using fresh bamboo shoots as raw material, obtaining quick-frozen bamboo shoots after precooking, cleaning, sterilizing and freezing, specifically comprising the following steps:

[0079] (1) Place qualified fresh bamboo shoots in a cooking tank, boil them in water for 40 minutes, and then cool them to room temperature with normal temperature running water;

[0080] (2) Remove the thick and old bamboo shoot shells by hand, and use a slingshot to remove the tender bamboo shoots and bamboo shoots, taking care to avoid damage to the bamboo shoots and ears;

[0081] (3) Remove the middle and lower part of the bamboo shoot skin, cut out a bamboo shoot stand of about 5 cm, and trim and clean it;

[0082] (4) After checking that there are no obvious coarse and old fibers, cut the raw materials into pieces of uniform size with a slicer;

[0083] (5) Select and remove semi-finished products and bamboo shoots that do not conform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com