Multifunctional rust-removing and paint-spraying robot for oil tank

A multi-functional, robotic technology, applied in the direction of dust removal, injection devices, chemical instruments and methods, etc., can solve the problems of reducing labor intensity, high labor intensity, and high work efficiency, so as to avoid potential safety hazards, reduce labor intensity, and improve work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

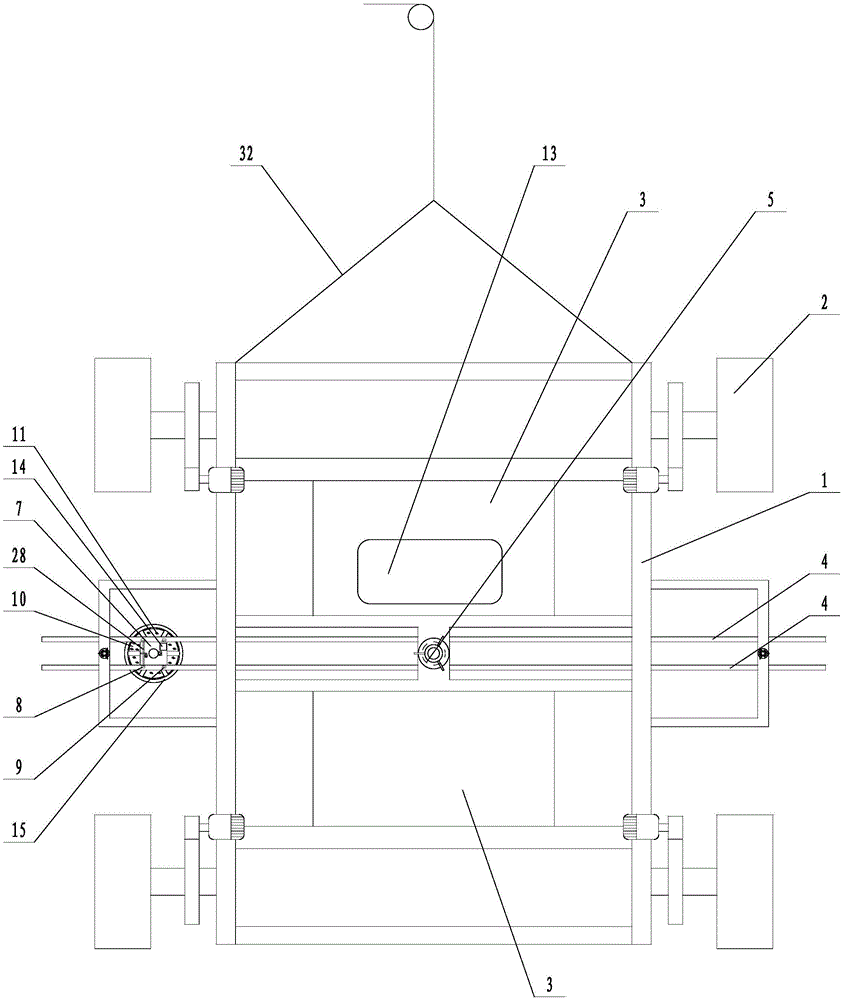

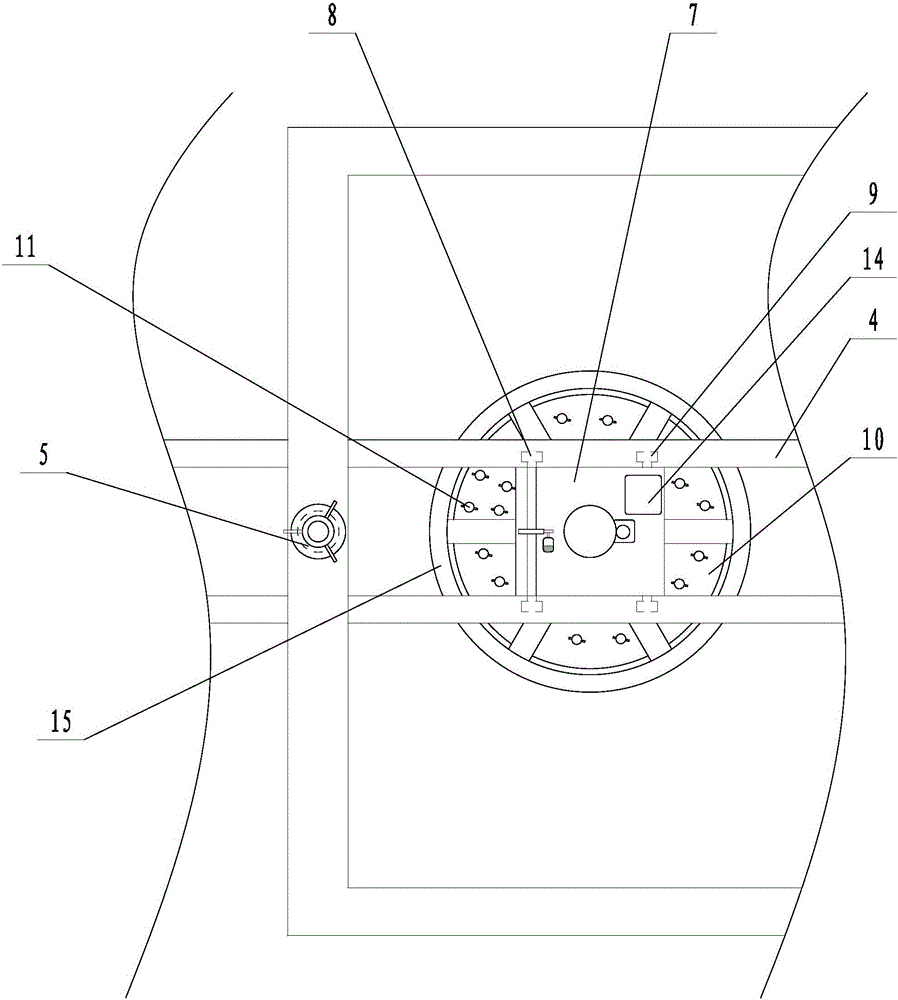

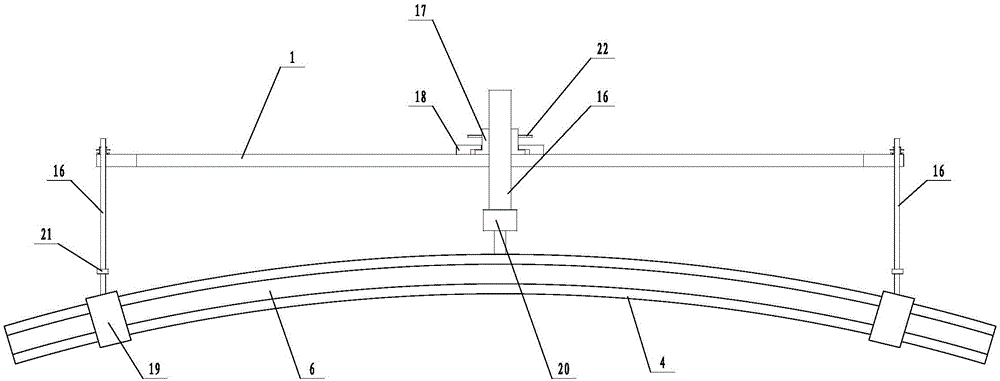

[0022] Embodiment: a kind of multifunctional oil tank derusting painting robot (see attached Figures 1 to 6 ), including a bracket 1, four driving wheels 2 are installed at the lower end of the bracket, and the four driving wheels are respectively installed at four corner positions of the bracket, and a downwardly extending support is provided on the bracket and the connection position of the driving wheel, and the driving wheel can rotate Installed on the stand. Each driving wheel is driven to an output shaft connected to a motor, and each motor independently drives a driving wheel to rotate. A magnetic suction block 3 is installed on the bracket, and two elastic rail rods 4 arranged at equal intervals are arranged under the bracket. A magnetic suction block is provided on both sides of the elastic rail rod on the bracket, and the lower surface of the magnetic suction block is in a concave arc. Shaped structure, the elastic track bar is an arc structure with a high middle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com