Hot stamping method of galvanized steel sheet

A technology of hot stamping and galvanized steel sheet, which is applied in the field of hot stamping, can solve problems such as brittle fracture of liquid metal, and achieve the effect of excellent mechanical strength and accelerated production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

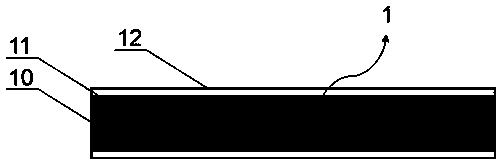

[0046] In Embodiment 1, a method for hot stamping of galvanized steel sheet is provided. Galvanized steel sheet 1 includes a steel sheet body 10 and a galvanized layer 11. Before hot stamping of galvanized steel sheet 1, the surface of galvanized steel sheet 1 is sprayed The heat layer 12, the heat absorbing layer 12 evenly covers the galvanized layer 11.

[0047] Wherein, the specific steps of the galvanized steel sheet hot stamping forming method are as follows:

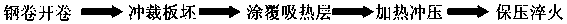

[0048] (1) Steel coil uncoiling: place the steel coil with galvanized layer on the uncoiler, uncoil the steel coil, and the steel strip after the uncoiled steel coil enters the cleaning station and straightening station, and then enters the plate through the pinch roller Blank blanking area;

[0049] (2) Punching the slab: The uncoiled, cleaned and straightened steel strip is sent to the punching station through the pinch roller, and first enters the metering section, and the metering roller sends the steel strip ...

Embodiment 2

[0057] In the second embodiment, a hot stamping forming method of galvanized steel sheet is provided. The galvanized steel sheet 1 includes the steel sheet body 10 and the galvanized layer 11. Before the hot stamping of the galvanized steel sheet 1, the heat-absorbing Layer 12, the heat absorbing layer 12 is evenly covered on the galvanized layer 11.

[0058] Wherein, the specific steps of the galvanized steel sheet hot stamping forming method are as follows:

[0059] (1) Steel coil uncoiling: place the steel coil with galvanized layer on the uncoiler, uncoil the steel coil, and the steel strip after the uncoiled steel coil enters the cleaning station and straightening station, and then enters the plate through the pinch roller Blank blanking area;

[0060] (2) Punching the slab: The uncoiled, cleaned and straightened steel strip is sent to the punching station through the pinch roller, and first enters the metering section, and the metering roller sends the steel strip inter...

Embodiment 3

[0068] In the third embodiment, a hot stamping forming method of galvanized steel sheet is provided. The galvanized steel sheet 1 includes a steel sheet body 10 and a galvanized layer 11. Before the hot stamping of the galvanized steel sheet 1, heat-absorbing Layer 12, the heat absorbing layer 12 is evenly covered on the galvanized layer 11.

[0069] Wherein, the specific steps of the galvanized steel sheet hot stamping forming method are as follows:

[0070] (1) Steel coil uncoiling: place the steel coil with galvanized layer on the uncoiler, uncoil the steel coil, and the steel strip after the uncoiled steel coil enters the cleaning station and straightening station, and then enters the plate through the pinch roller Blank blanking area;

[0071] (2) Punching the slab: The uncoiled, cleaned and straightened steel strip is sent to the punching station through the pinch roller, and first enters the metering section, and the metering roller sends the steel strip intermittently...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sublimation point | aaaaa | aaaaa |

| adhesion amount | aaaaa | aaaaa |

| sublimation point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com