Electromagnetic induction type rapid metal melting spray head for 3D metal printer

An electromagnetic induction and printer technology, applied in the field of 3D metal printing, can solve the problems of inability to complete the forming and manufacturing of large metal components, cannot realize fast printing, and cannot be popularized and applied, and achieves fast printing, high cost performance, and high energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

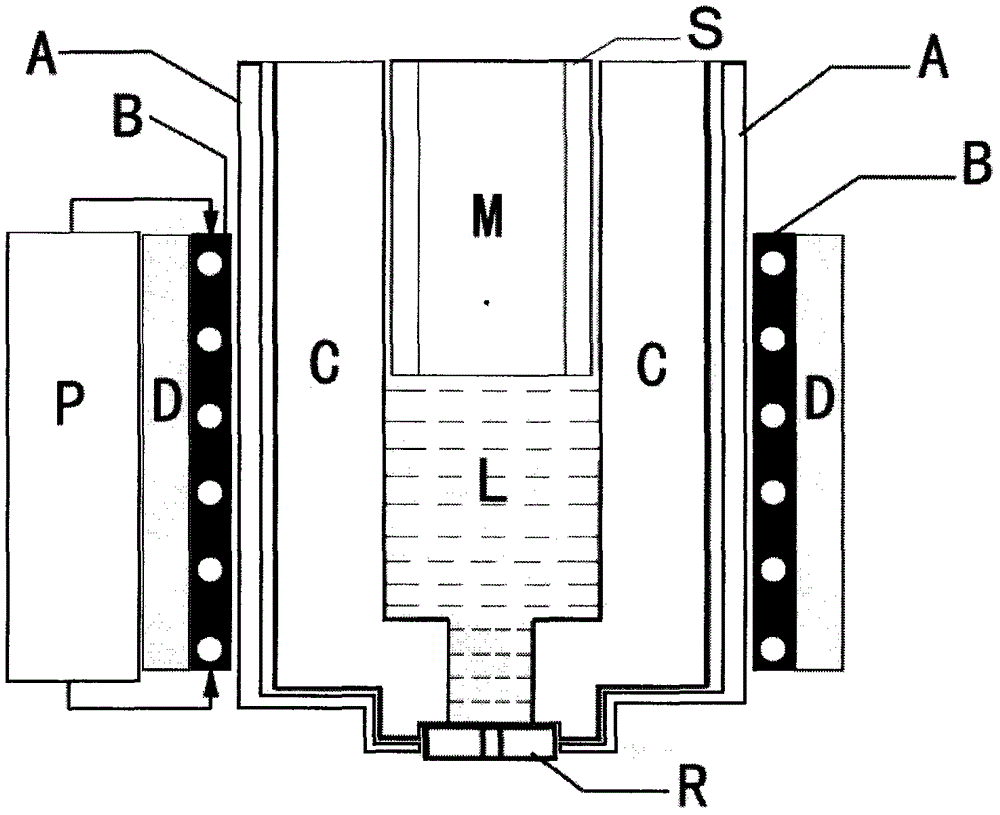

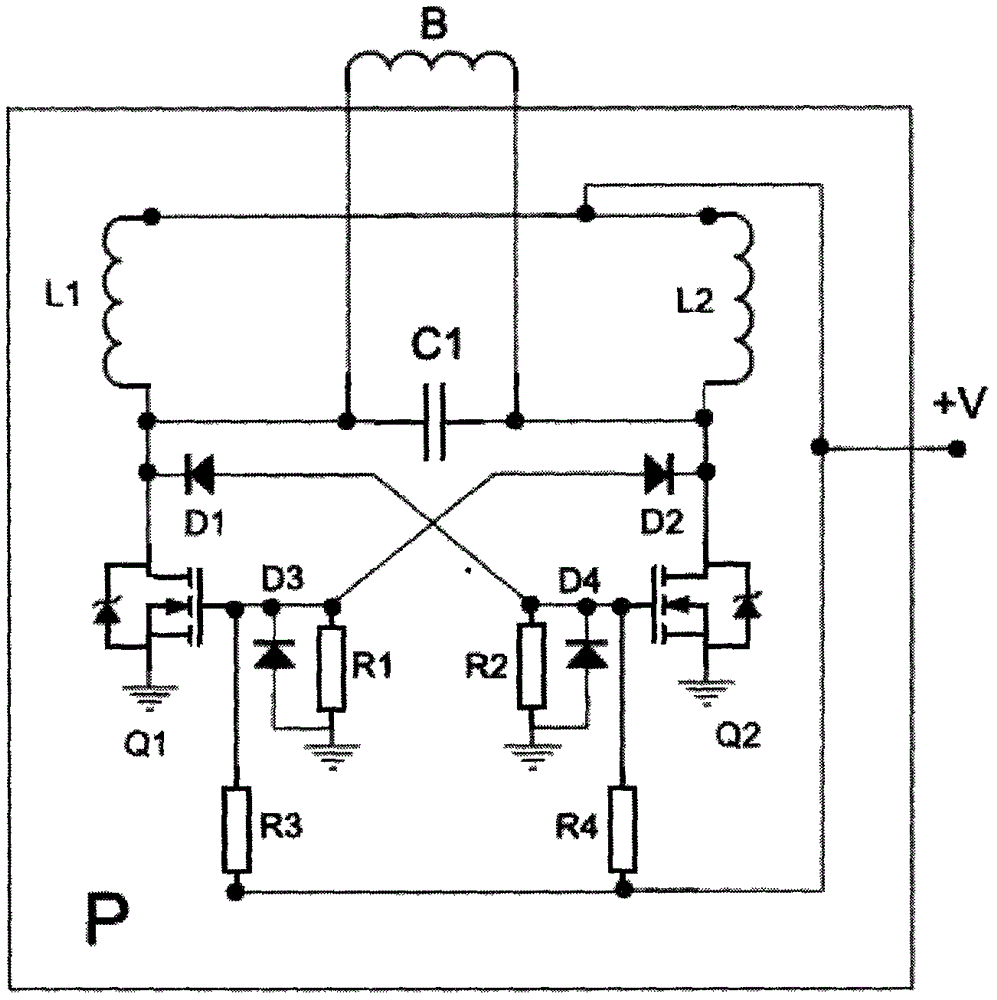

[0023] exist figure 1 Among them, the electromagnetic induction fast metal melting nozzle for 3D metal printer consists of nozzle (R), crucible (C), heat insulation layer (A), medium and high frequency inverter power supply (P), electromagnetic induction coil (B), cooling device (D), the metal to be melted (M) and the feeding device (S). The electromagnetic induction coil (B) surrounds the crucible (C) through the heat insulating layer (A), and the cooling device (D) provides cooling for the electromagnetic induction coil (B) and the medium and high frequency inverter power supply (P), and the medium and high frequency inverter power supply (P) Drive the electromagnetic induction coil (B), so that the metal to be melted (M) in the crucible (C) is rapidly melted by electromagnetic induction to form a metal fluid or liquid (L), and the metal fluid or liquid (L) is sprayed through the nozzle (R) out. As for the ejection method, several mature methods can be used at present, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com