Glass machining system for filtering grinding liquid and adjusting absorption intensity

A processing system and glass technology, applied in the direction of grinding workpiece supports, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of affecting the fixing effect, increasing energy consumption, rapid wear of grinding heads, etc., to reduce equipment maintenance costs , The use of safe and reliable, the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

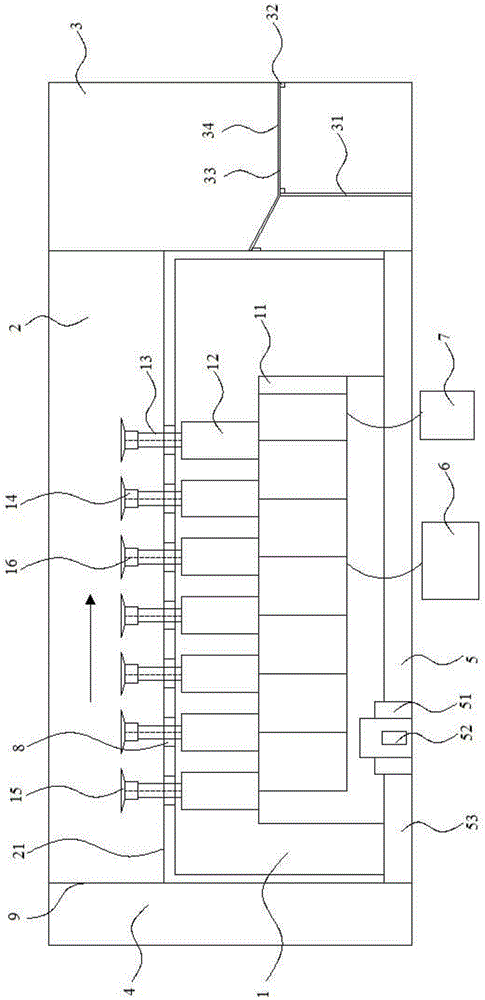

[0026] Such as figure 1As shown, a glass processing system with filter grinding and adjustment of adsorption strength includes a glass fixing device 1, a grinding fluid cooling tank 2, a grinding fluid filtering tank 3, a grinding fluid cooling tank 4 and A grinding fluid circulation system 5, the grinding fluid cooling tank 2, the grinding fluid filter tank 3, the grinding fluid cooling tank 4 and the grinding fluid circulation system 5 are connected, the glass Both the fixing device 1 and the grinding fluid circulation system 5 are connected to the power supply 7, and a base plate 21 is provided below the grinding fluid cooling box 2, and a plurality of upper thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com