Wood carbonizing process

A technology of wood and craftsmanship, applied in wood processing equipment, wood treatment, impregnated wood, etc., can solve problems such as fire, achieve the effects of improving uniformity, preventing uneven heating, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

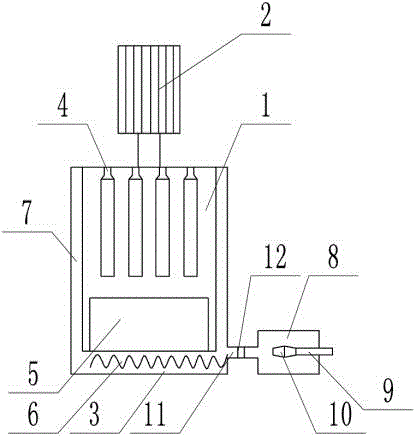

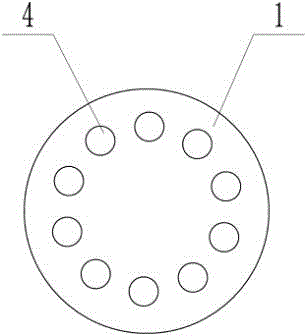

[0028] The reference signs in the drawings of the description include: carbonization box 1, motor 2, heating channel 3, vacuum suction cup 4, collection box 5, hot gas discharge pipe 6, gas flow channel 7, combustion chamber 8, gas pipe 9, burner nozzle 10 , air guide tube 11, valve 12.

[0029] A kind of technique of wood carbonization of the present invention, step is as follows:

[0030] The first step is cutting, the wood is cut into long strips by cutting machine;

[0031] The second step is to build a carbonization box. A cylindrical copper box is selected as the carbonization box. There is a layer of thermal insulation material on the outside of the carbonization box. A motor is connected to the top of the box. There is a vacuum suction cup on the top of the carbonization box, a collection box is placed under the carbonization box, a spiral hot gas discharge pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com