multifunctional glass film

A multi-functional, glass film technology, applied in the direction of glass/slag layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of no heat insulation ability, high cost, poor one-way perspective effect, etc. , to achieve the effect of reducing indoor glare, enhancing environmental resistance, and reducing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

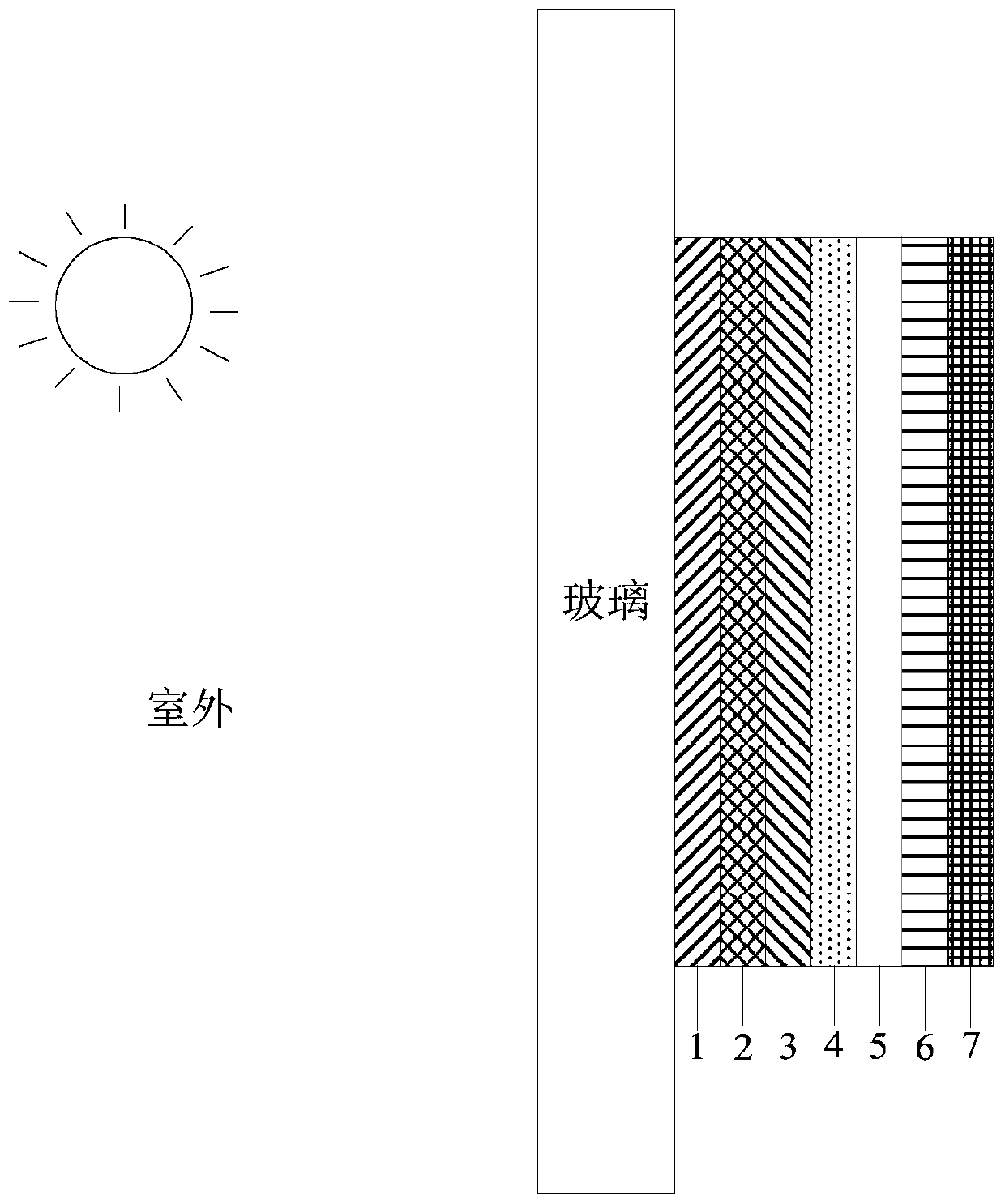

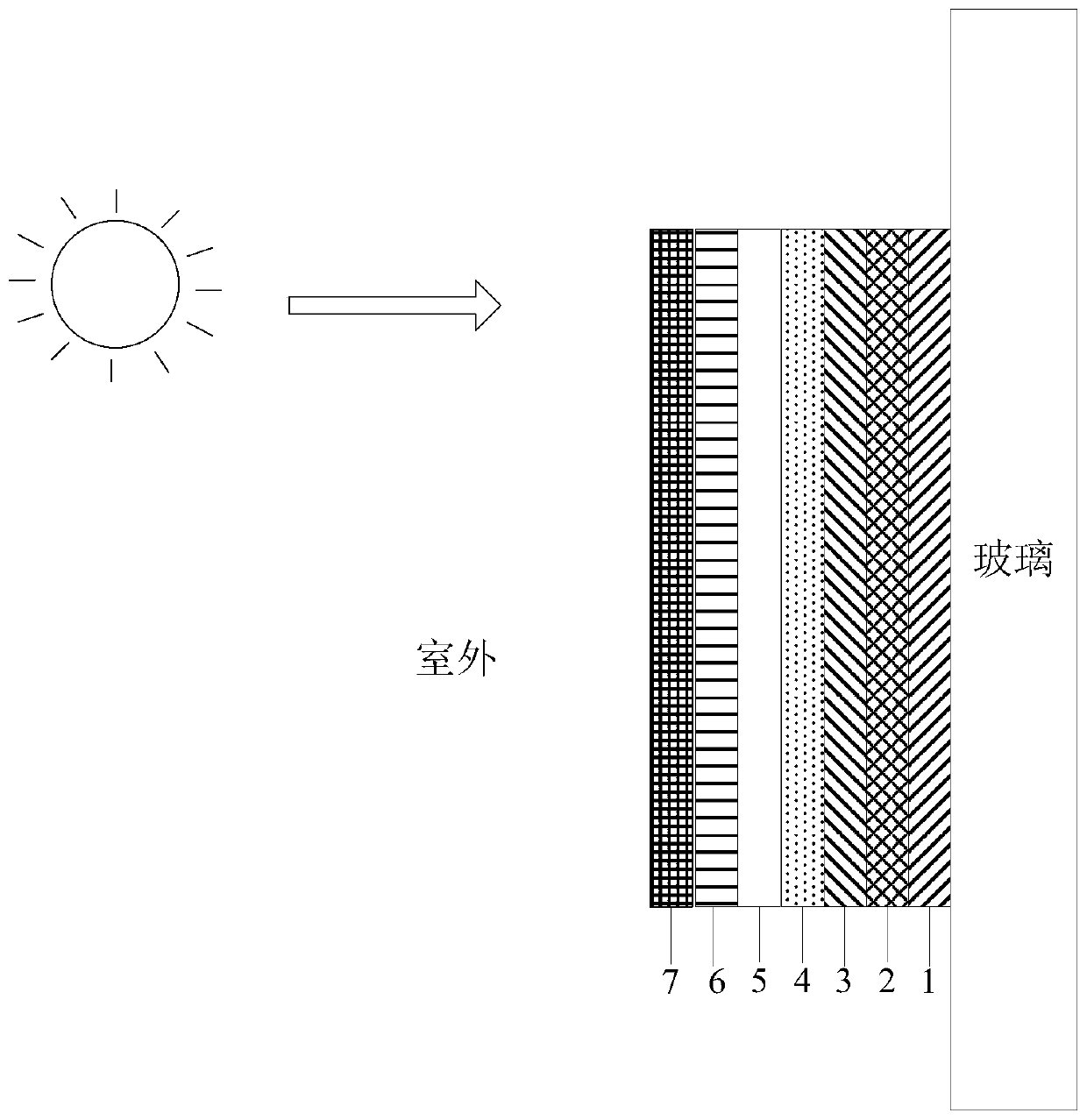

[0064] Example 1: The second substrate layer is colorless and transparent PET, with a thickness of 38 μm. The winding magnetron sputtering coating machine is used on the second substrate layer, the initial vacuum is 6×10E-6Pa, the working gas is Ar, and ZnAlOx, NiCr, Ag, NiCr, ZnAlOx, the film thickness is 40nm, 5nm, 10nm, 1nm, 15nm.

Embodiment 2

[0065] Embodiment 2: The second substrate layer is colorless and transparent PET with a thickness of 50 μm. The winding magnetron sputtering coating machine is used on the second substrate layer, the initial vacuum is 6×10E-6Pa, the working gas is Ar, and NbOx, NiCr, Ag, NiCr, NbOx, the film thickness is 30nm, 4nm, 10nm, 2nm, 10nm.

Embodiment 3

[0066] Example 3: The second substrate layer is a bulk colored (blue) PET with a visible light transmittance of 70%, and the thickness is 50 μm. The winding magnetron sputtering coating machine is used on the second substrate layer, the initial vacuum is 5×10E-6Pa, the working gas is Ar, and TiOx, NbOx, NiCr, and NiCr are plated in sequence according to the sequence of substrate movement. Ag, NiCr, Ag, NiCr, SiNx, the film thickness is 10nm, 25nm, 9nm, 9nm, 6nm, 9nm, 2nm, 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com