AGV (Automatic Guided Vehicle) independent suspension shock-absorbing driving unit

A technology of independent suspension and drive unit, applied in the direction of suspension, elastic suspension, motion deposition, etc., can solve the problems of poor rigidity, easy vibration, easy deformation of the drive seat structure, etc., to avoid falling of goods and prolong the use The effect of good life and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make those skilled in the art understand the present invention better, the present invention will be further described below in conjunction with specific embodiment:

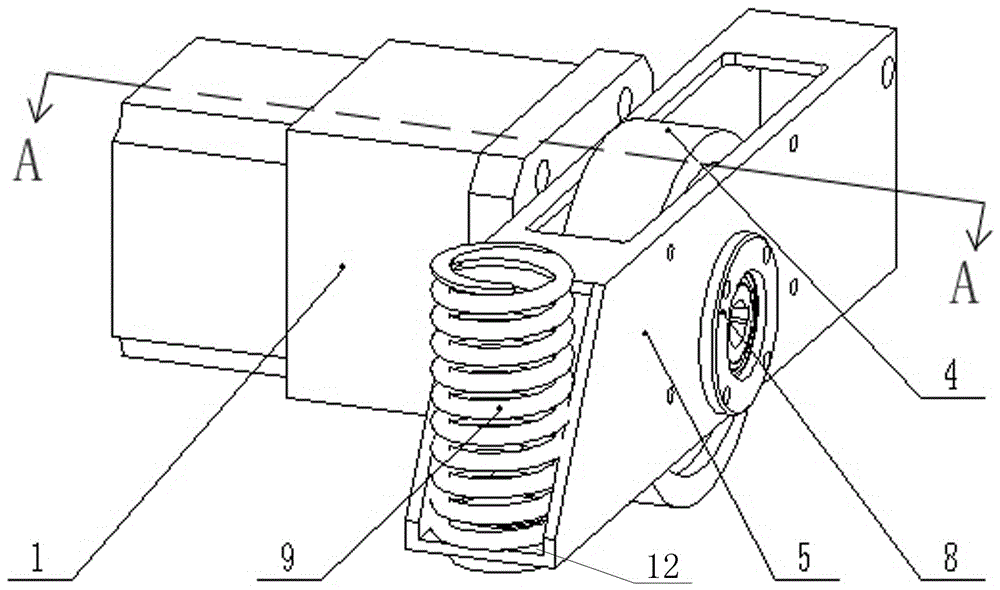

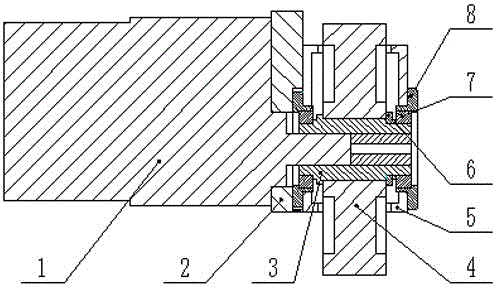

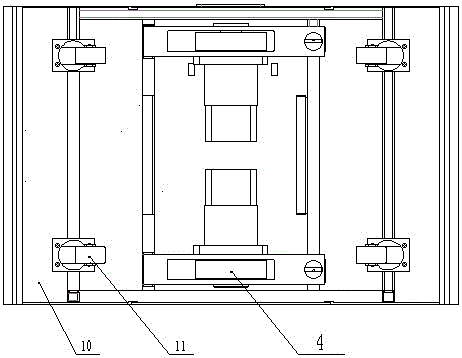

[0017] Such as figure 1 and figure 2 As shown, an AGV trolley independent suspension shock-absorbing drive unit includes a DC brushless motor 1, and the DC brushless motor 1 is connected with a drive wheel shaft 3 and a drive wheel 4, and the DC brushless motor 1 is also equipped with The driving motor connecting seat 2, the driving motor connecting seat 2 is located between the DC brushless motor 1 and the driving wheel 4, the driving wheel 4 is installed on the driving seat 5 through the driving wheel shaft 3, and the driving seat 5 is sleeved on the outside of the driving wheel 4 ; One side of the drive seat 5 is also fixed with a damping spring 9 .

[0018] A deep groove ball bearing 7 is installed on the drive wheel shaft outside the drive seat, and a drive bushing 6 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com