An online micro-processing method for yarn winding

A micro-processing and yarn technology, which is applied in the field of online micro-processing of yarn winding, can solve the problems of changing the overall performance of the yarn, limited force, large amount of hairiness, etc., to achieve enhanced wear resistance, good film-forming properties, Adhesive and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

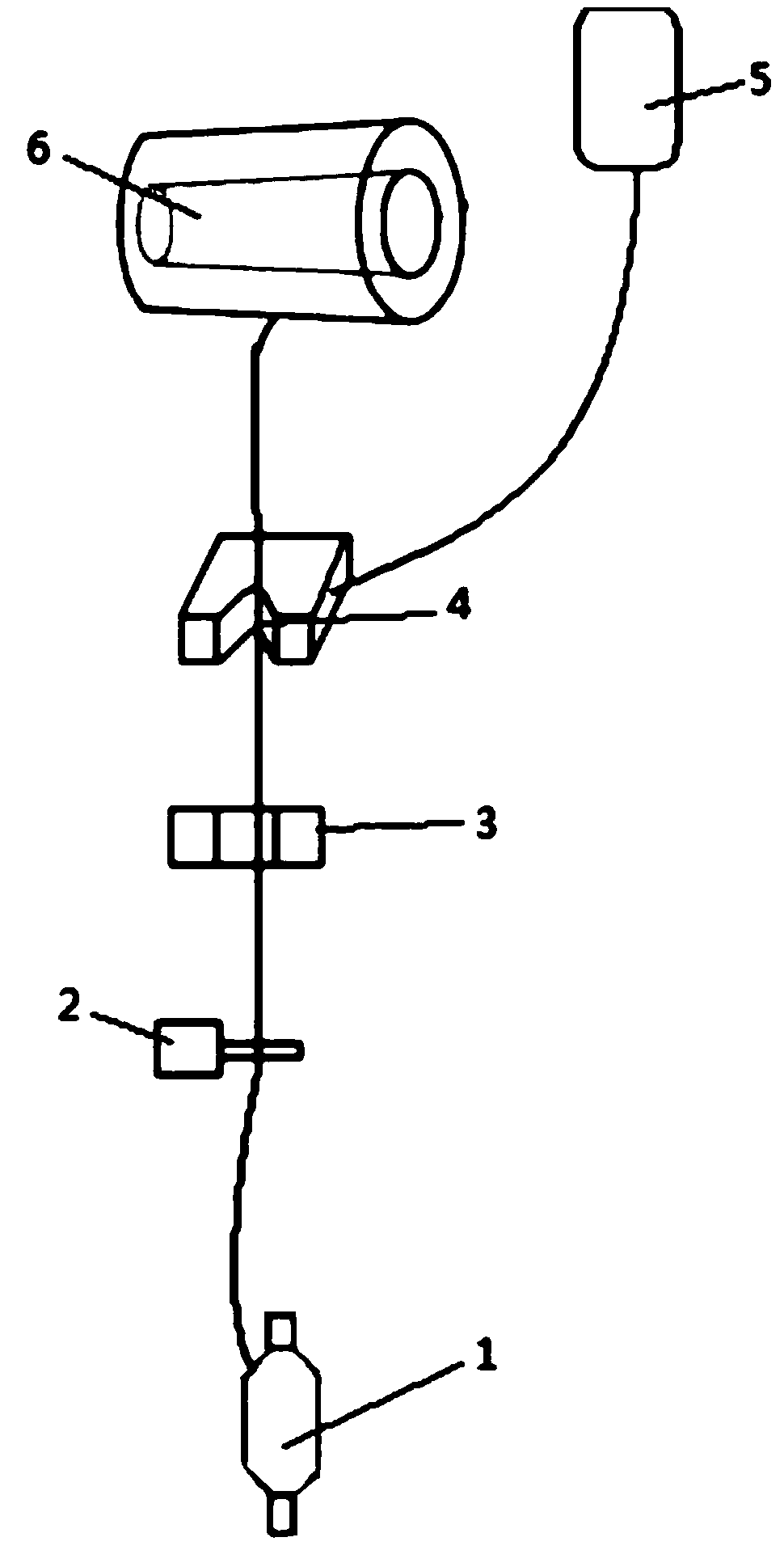

[0015] The yarn is pure cotton 40 pounds, the slurry used is polyvinyl alcohol slurry with a solid content of 0.2%, the number average molecular weight is 60000, the addition rate is 1g / min, and the flexible processing module is a polyvinyl alcohol sponge module. The process flow is as follows:

[0016] After the yarn is unwound from bobbin 1 at a speed of 1200m / min, it passes through electronic yarn clearer 2 and air splicer 3, and then passes through yarn surface structure micro-processing device 4 filled with micro-processing slurry, and then passes through the groove drum. 6 is wound into bobbins. When the yarn passes through the yarn surface structure micro-processing device, a 1.5mm flexible processing module is embedded in the yarn surface structure micro-processing device. Attach and fix, and form a size film layer accounting for 1 / 8 of the yarn diameter after natural drying in the air.

Embodiment 2

[0018] The yarn is pure wool 80 pounds, the size used is polyacrylic acid size with a solid content of 2%, the number average molecular weight is 160,000, the addition rate is 0.4g / min, and the flexible processing module is a low-density polyether sponge module. Its technological process is as follows:

[0019] After the yarn is unwound from bobbin 1 at a speed of 800m / min, it passes through electronic yarn clearer 2 and air splicer 3, and then passes through yarn surface structure micro-processing device 4 filled with micro-processing slurry, and then passes through the groove drum. 6 is wound into bobbins. When the yarn passes through the yarn surface structure micro-processing device, a flexible processing module of 0.5 mm is embedded in the yarn surface structure micro-processing device, and the hairiness on the yarn surface is subjected to friction, obeys the yarn surface, and is stuck by the size at the same time. Attach and fix, and form a size film layer accounting fo...

Embodiment 3

[0021] The yarn is ramie 20 pounds, the slurry used is polyvinyl alcohol slurry with a solid content of 1.3%, the number average molecular weight is 70000, the addition rate is 2g / min, and the flexible processing module is a polyurethane sponge module. Its technological process is as follows:

[0022] After the yarn is unwound from bobbin 1 at a speed of 1000m / min, it passes through electronic yarn clearer 2 and air splicer 3, and then passes through yarn surface structure micro-processing device 4 filled with micro-processing slurry, and then passes through the groove tube. 6 is wound into bobbins. When the yarn passes through the yarn surface structure micro-processing device, a 3.5mm flexible processing module is embedded in the yarn surface structure micro-processing device. Attach and fix, and form a size film layer accounting for 1 / 5 of the yarn diameter after natural drying in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com