Method for recycling silico-alumino-phosphate molecular sieve filtering fluid, and device for re-preparing molecular sieve

A silicon-aluminum-phosphorus molecular sieve and filter solution technology, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve catalyst, molecular sieve characteristic silicon-aluminophosphate, etc., can solve the problems of large waste liquid discharge and high treatment cost, and reduce waste liquid emissions, reduce pollution, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

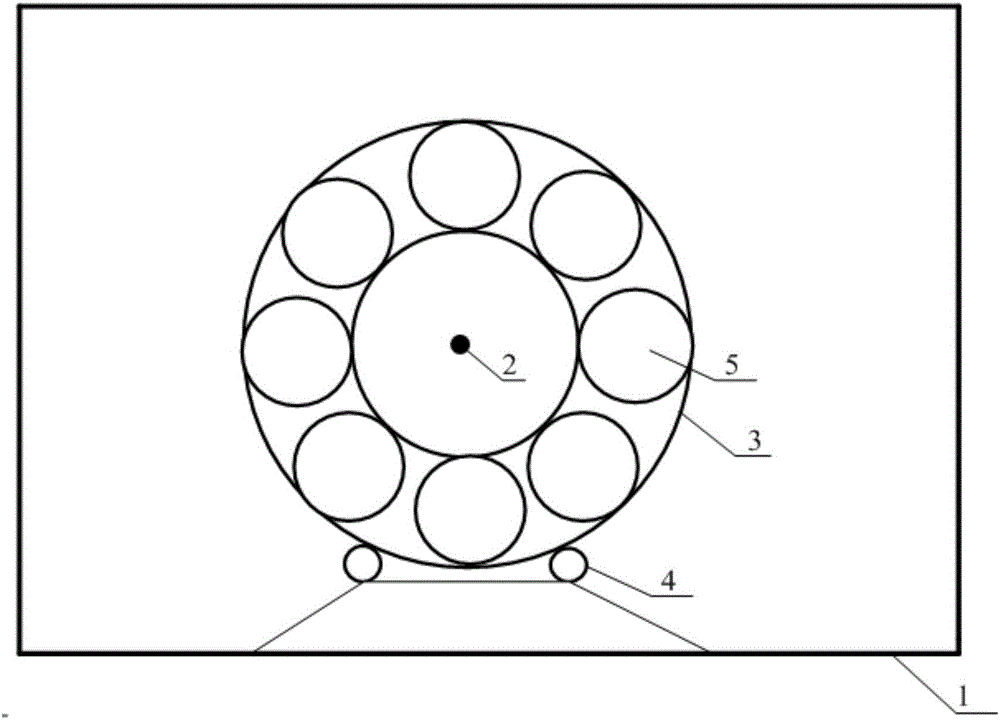

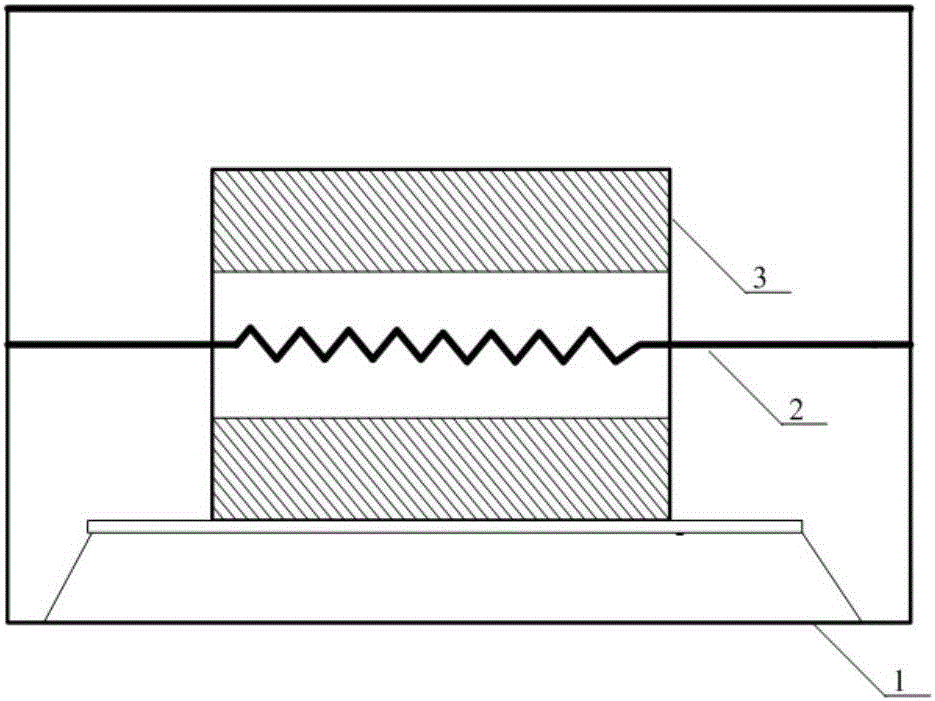

[0035] The filtrate obtained after the final stage of washing is added to the seed crystals ground to 0.2μm and mixed uniformly; and the obtained mixture is used as the mother liquor for preparing the new formula of silico-aluminum-phosphorus molecular sieve to prepare the new formula of silico-aluminum-phosphorus Molecular sieve. When preparing the new formula of silico-alumina-phosphorus molecular sieve, the mother liquor obtained above is put into the re-preparation molecular sieve device. The re-preparation molecular sieve device includes an oven 1, a ring filling tank 3 and several small synthesis reactors 5. The oven 1 The bottom of the inner cavity is provided with a controllable roller 4, the ring filling tank 3 lies on the roller 4, and the small synthesis kettle 5 is filled along the annular cavity of the ring filling tank 3. Installed and fixed. Put the mother liquor of the silico-alumino-phosphorus molecular sieve into each small synthesis kettle 5, turn on the pow...

Embodiment 2

[0040] The filtrate obtained after the final stage of washing is added to the seed crystals ground to 1 μm and mixed uniformly; and the obtained mixture is used as the mother liquor for preparing the new formula of silico-aluminum-phosphorus molecular sieve, and then the new formula of silico-aluminum-phosphorus molecular sieve is prepared . When preparing the new formula of silico-aluminum-phosphorus molecular sieve, the mother liquor obtained above is put into a molecular sieve device, and the silico-aluminum-phosphorus molecular sieve is prepared by heating and curing.

Embodiment 3

[0042] The filtrate obtained after the final stage of washing is added to the seed crystals ground to 0.6μm and mixed uniformly; and the obtained mixture is used as the mother liquor for preparing the new formula of silicoaluminophosphate molecular sieve to prepare the new formula of silicoaluminophosphate Molecular sieve. When preparing the new formula of silico-aluminum-phosphorus molecular sieve, the mother liquor obtained above is put into the molecular sieve device again, and the silico-aluminum-phosphorus molecular sieve is prepared by heating and curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com