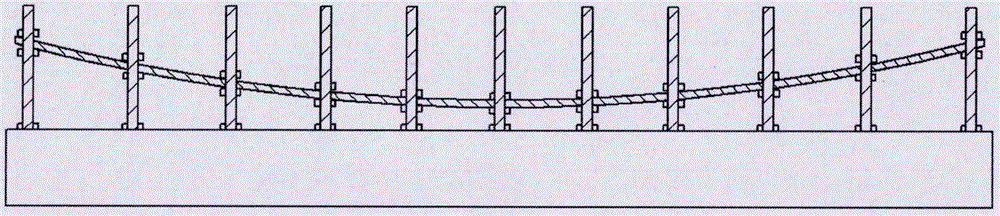

Adjustable glass hot-bending mould

An adjustable and glass technology, applied in the field of mold manufacturing, can solve the problems of poor surface quality, affecting surface quality, high mold cost, etc., and achieve the effects of long service life, high molding quality and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The chemical composition of the D-type graphite cast iron of the present embodiment is as follows: 3.0wt% C, 0.9wt% Si, 1.2wt% Mn, 2.0wt% Cu, 0.22wt% Ti, 0.05wt% Cr, 0.03wt% Al, 0.02wt% of P, 0.01wt% of S, the balance is Fe and unavoidable impurities. Put the raw material of cast iron into the medium frequency induction furnace to melt according to the ratio, and make the molten iron superheated, measure the temperature through the thermocouple and adjust the temperature of the molten iron to 1500-1550°C; use Si-Fe inoculant to inoculate the molten iron, the particle size of the inoculant 3-5mm, and the addition amount is 0.3wt% of molten iron. In actual operation, it should be ensured that the inoculant can be fully and evenly dissolved into the molten metal in the ladle. After the operation is completed, the slag can be removed and then poured. for 10.0 hours.

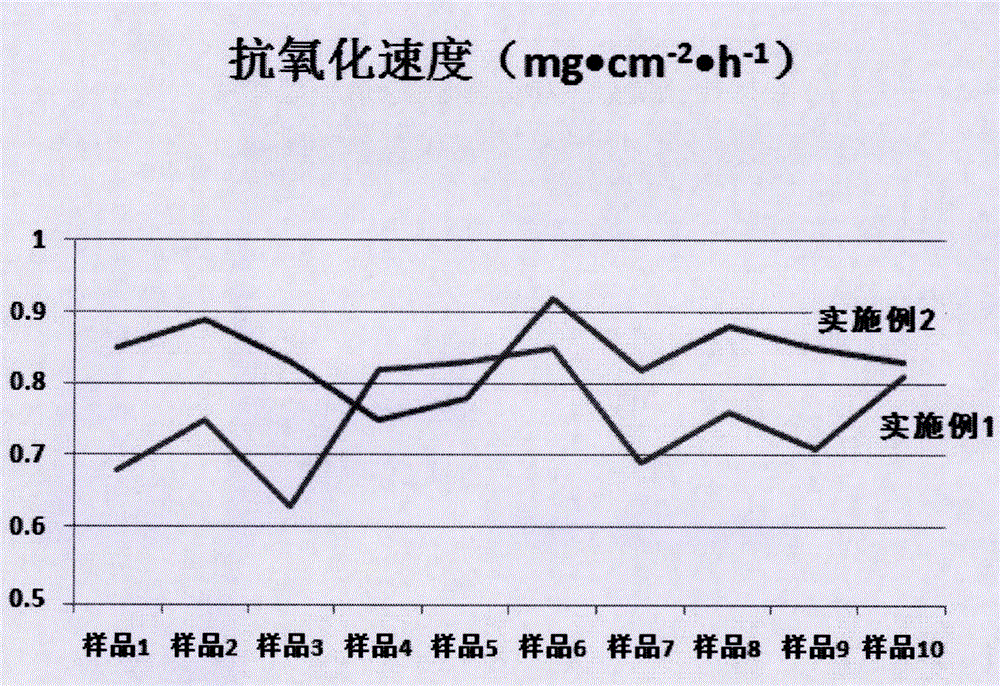

Embodiment 2

[0019] The chemical composition of the D-type graphite cast iron of the present embodiment is as follows: 3.2wt% of C, 0.65wt% of Si, 1.0wt% of Mn, 1.8wt% of Cu, 0.12wt% of Ti, 0.08 of Cr, 0.05 of Al , 0.02wt% of P, 0.01wt% of S, and the balance is Fe and unavoidable impurities. Put the raw material of cast iron into the medium frequency induction furnace to melt according to the ratio, and make the molten iron superheated, measure the temperature through the thermocouple and adjust the temperature of the molten iron to 1500-1550°C; use Si-Fe inoculant to inoculate the molten iron, the particle size of the inoculant 3-5mm, and the addition amount is 0.3wt% of molten iron. In actual operation, it should be ensured that the inoculant can be fully and evenly dissolved into the molten metal in the ladle. After the operation is completed, the slag can be removed and then poured. for 10.0 hours.

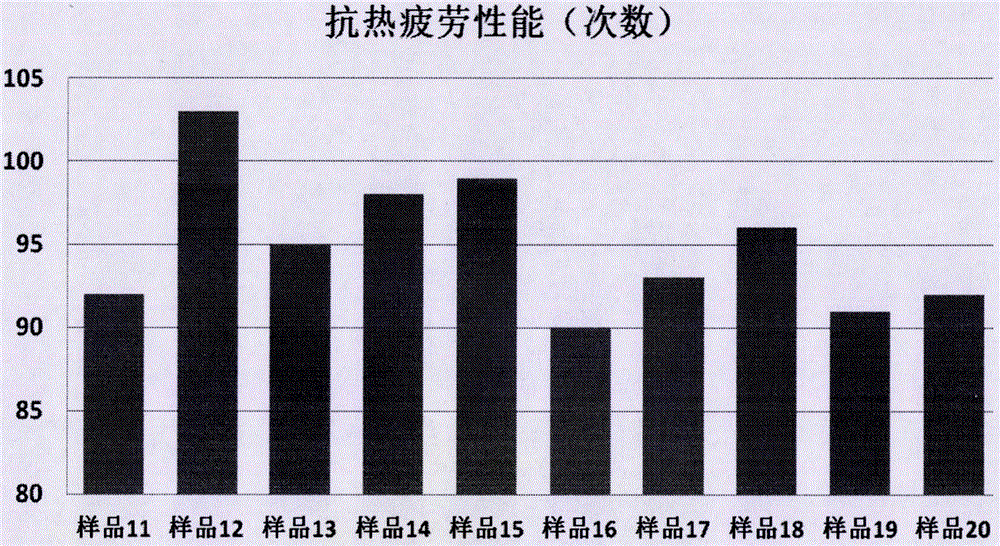

[0020] In order to verify the performance of the D-type graphite cast iron as a moul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com