Manufacturing method for performing cross-stitch inkjet printing on dacron

A production method and inkjet printing technology, applied in printing, typewriters, printing devices, etc., can solve problems such as inability to produce works, easy embroidery of wrong grids, complicated processes, etc., and achieve the effects of realistic effects, clear outlines, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

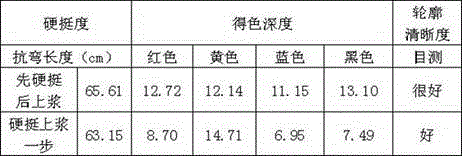

[0020] Embodiment one, a kind of preparation method of polyester fabric ink-jet printing cross-stitch comprises the following steps:

[0021] (1) Stiffen the polyester whitening cloth with acrylate stiffening agent 506 first, dry it, and wait for sizing treatment;

[0022] (2) Prepare a polysaccharide acidic digital paste DM-8813 with a certain viscosity to sizing the stiffened polyester fabric, dipping and rolling twice, drying, and waiting for digital printing;

[0023] (3) Apply digital printer inkjet printing, the inkjet volume is 100%, after printing, steam, and dry;

[0024] In the stiffening finishing process in the step (1), the dosage of the acrylate-based stiffening agent 506 is 80-400 g / L, two dippings and two rollings, drying, and shaping (130-150° C.×30 sec).

[0025] In the sizing treatment process in the step (2), the amount of acidic digital paste DM-8813 is 10-30%, the amount of citric acid is 0.1-0.3%, stir evenly, and the apparent viscosity of the prepared ...

Embodiment 2

[0029] Embodiment two, a kind of preparation method of polyester fabric ink-jet printing cross-stitch comprises the following steps:

[0030] (1) Stiffen the polyester whitening cloth with acrylate stiffening agent 506 first, dry it, and wait for sizing treatment;

[0031] (2) Prepare a polysaccharide acidic digital paste DM-8813 with a certain viscosity to sizing the stiffened polyester fabric, dipping and rolling twice, drying, and waiting for digital printing;

[0032] (3) Apply digital printer inkjet printing, the inkjet volume is 100%, after printing, steam, and dry;

[0033] In the stiffening finishing process in the step (1), the dosage of the acrylate-based stiffening agent 506 is 80-400 g / L, two dippings and two rollings, drying, and shaping (130-150° C.×30 sec).

[0034] In the sizing treatment process in the step (2), the amount of acidic digital paste DM-8813 is 10-30%, the amount of citric acid is 0.1-0.3%, stir evenly, and the apparent viscosity of the prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com