Eddy-current self-frequency-conversion tuned mass damper

A technology of tuning mass damping and self-converting frequency, which is applied to building components, earthquake resistance, building types, etc. It can solve problems such as difficult to adjust its own frequency, frequency deviation between frequency and structure, and decrease in vibration damping effect, so as to simplify analysis and design and avoid friction , the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

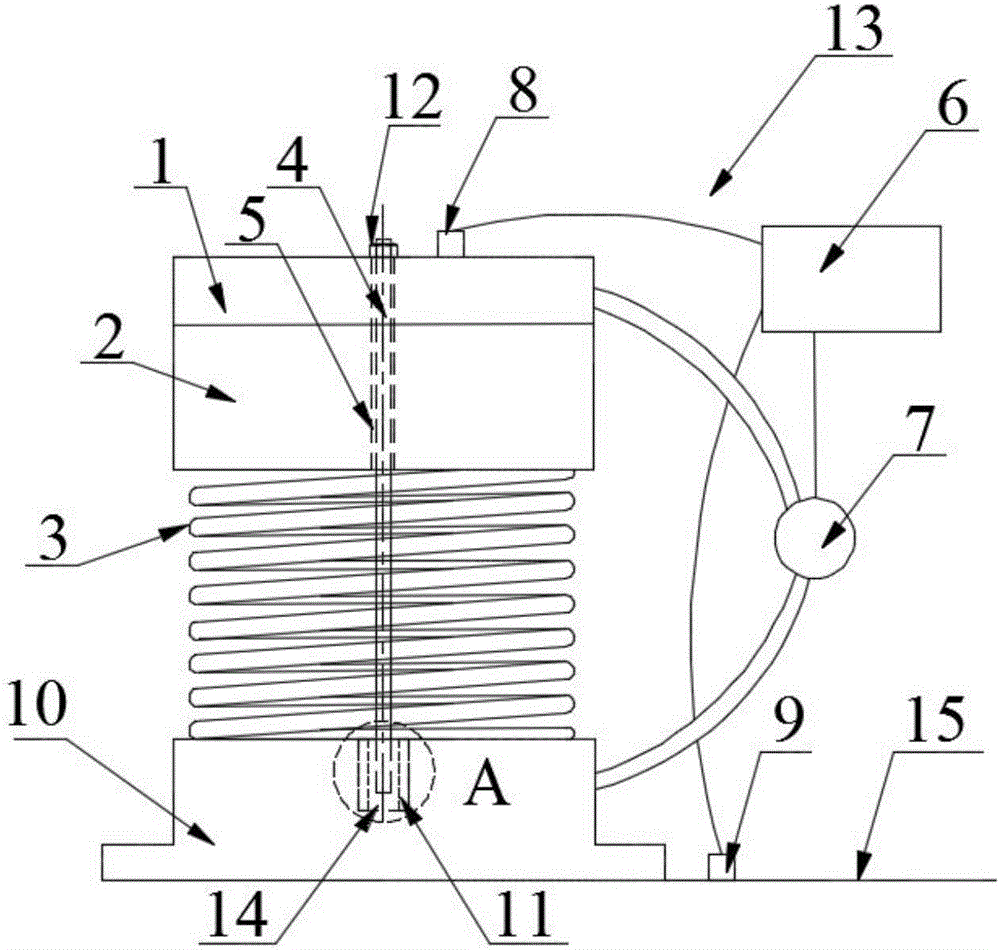

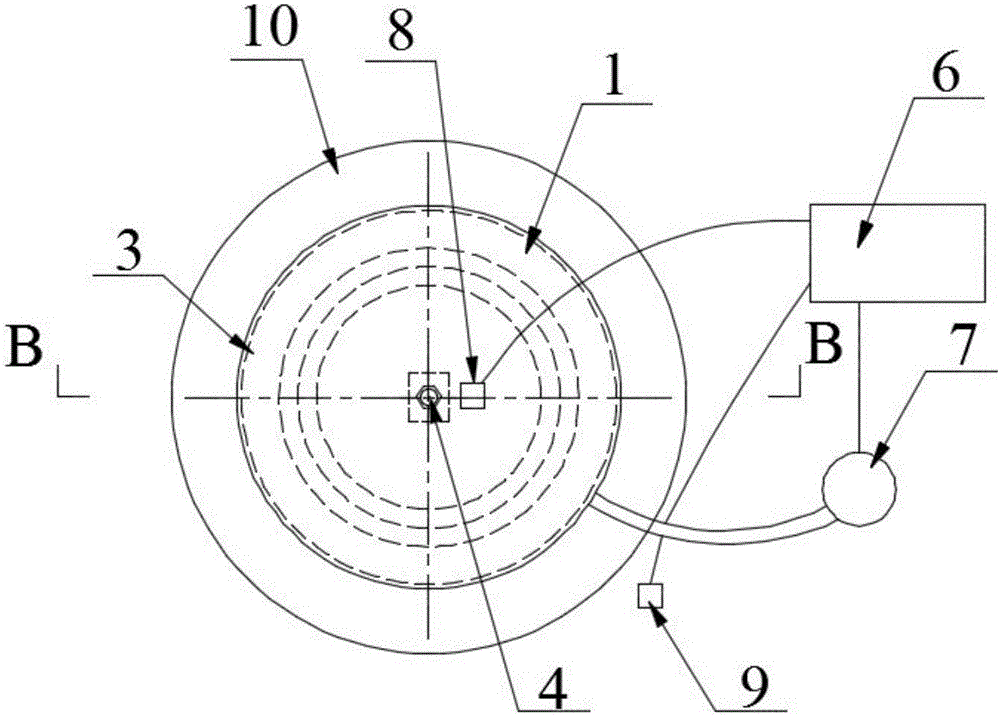

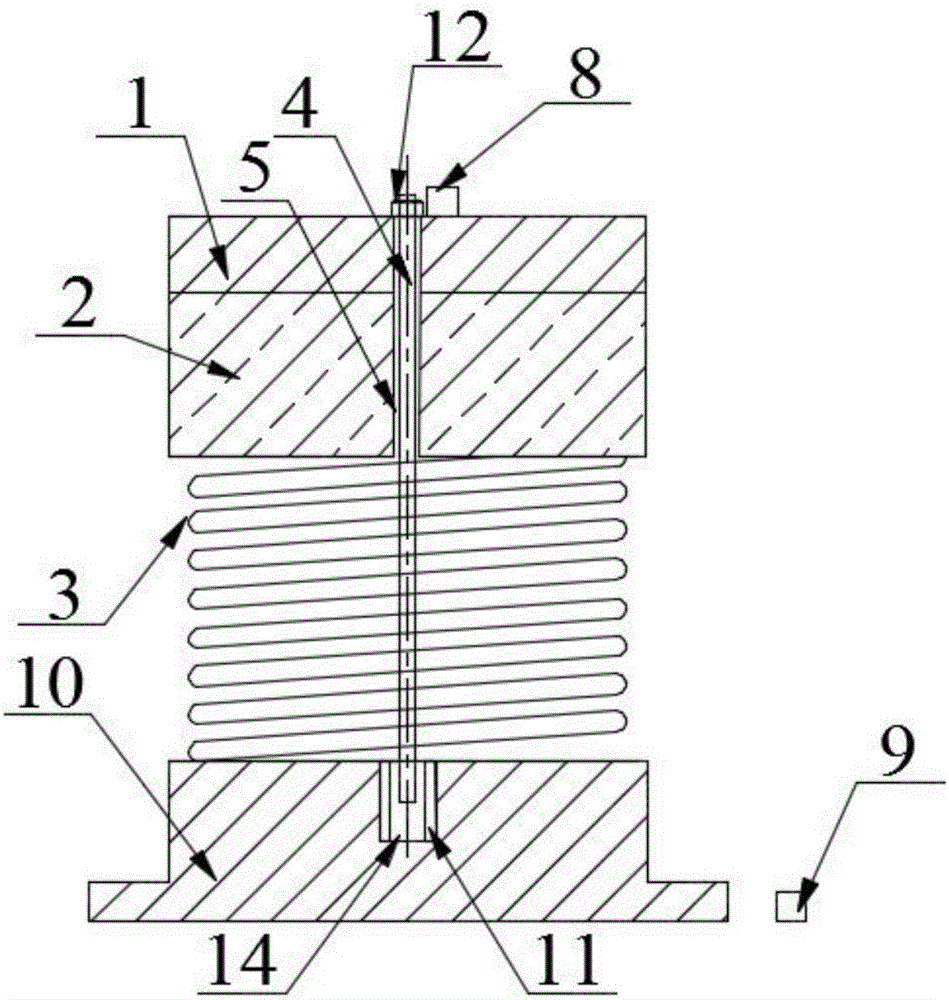

[0029] Such as Figure 1-3 As shown, the present invention provides an eddy current self-conversion frequency tuning mass damper, which is composed of a fixed mass 2, a variable mass 1, a permanent magnet rod 4, an electromagnetic slot 14, a conductor plate 11, and a spring 3 for adjustment The quality block 10 and the servo control assembly 13 are composed, wherein:

[0030] The bottom end of the spring 3 is connected to the top of the adjustable mass 10, the top of the spring 3 is connected to the bottom of the fixed mass 2, the variable mass 1 is fixedly arranged on the top of the fixed mass 2, and the variable mass 1 And the center of the fixed mass 2 is provided with a permanent magnet rod channel 5.

[0031] The electromagnetic slot 14 is located at the center of the top surface of the adjustable mass 10, and the upper end of the permanent magnet rod 4 is fixed on the top of the variable mass 1 with a nut 12. After passing through the permanent magnet rod channel 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com