Air tightness detection system applied to new energy battery packs and detection method thereof

An air-tightness detection and battery pack technology, which is used in liquid/vacuum measurement for liquid-tightness, and by measuring the fluid's acceleration/deceleration rate, etc., which can solve difficult monitoring, unstable air pressure, troublesome air source adjustment, etc. problems, to achieve the effect of traceability and convenient analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The basic control principle of the system is realized through the following steps:

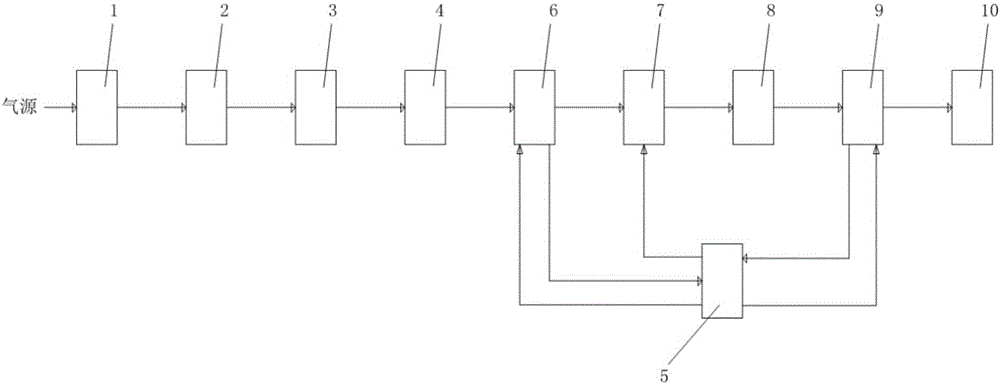

[0030] Step (1): The air source passes through the triple piece 1, and is connected to the SMC precision pressure regulating valve 2 and the SMC digital display precision pressure switch 3. Through the SMC digital display precision pressure switch 3, the SMC precision pressure regulating valve 2 can be adjusted to obtain an air source pressure with an accuracy of 0.001Mpa.

[0031] Step (2): After the air source passes through the SMC digital display precision pressure switch 3, it is connected to the SMC precision proportional valve 4, and the air source passing through the SMC precision proportional valve 4 is connected to the solenoid valve 6. The data acquisition line of the SMC precision proportional valve 4 is connected to the software control device 5, so that the software control device 5 collects the air pressure value after passing through the proportional valve 4.

[0032] S...

Embodiment 2

[0038] The operation steps of the air tightness detection system are as follows:

[0039] Step A: The equipment is ventilated, powered on, and the power switch of the equipment is turned on. Turn on the industrial computer of the test system, open the software, log in the account, and enter the software operation interface;

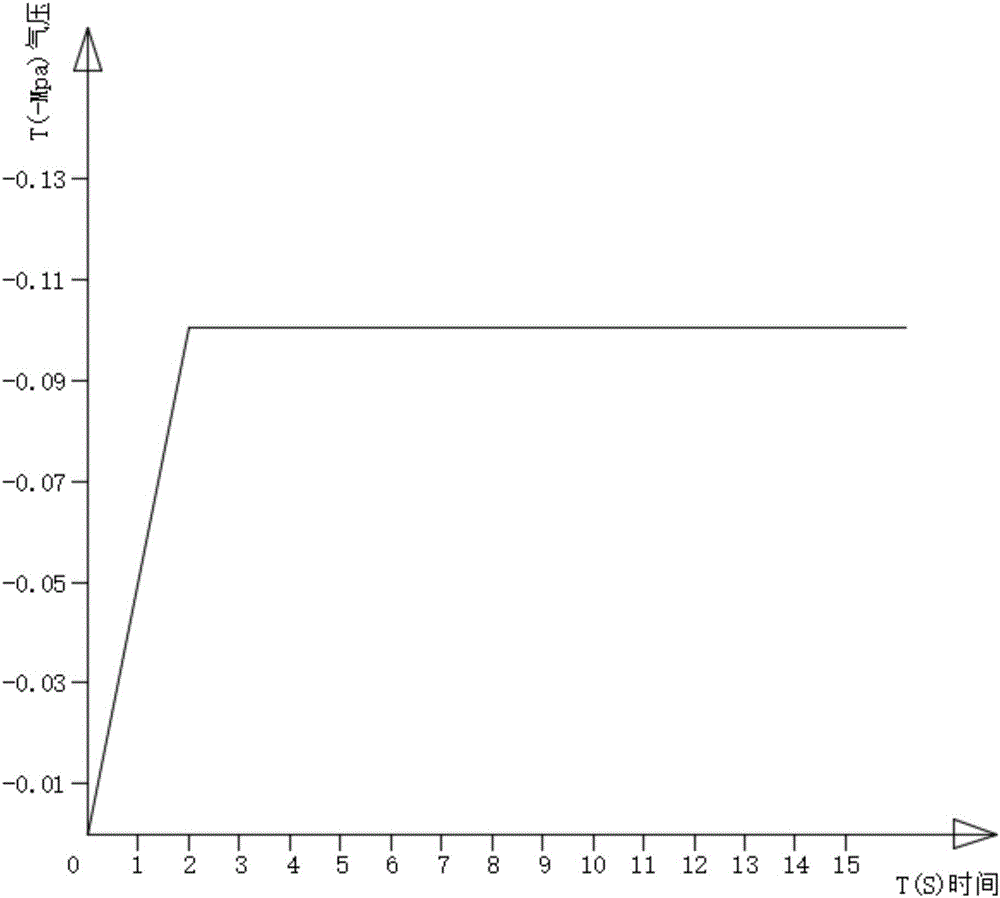

[0040] Step B: Open the parameter setting interface, input the air pressure setting value -0.1Mpa, the pumping time is 5S, and the pressure holding time is 60S (the time of pumping and holding pressure can be set according to the size of the battery pack);

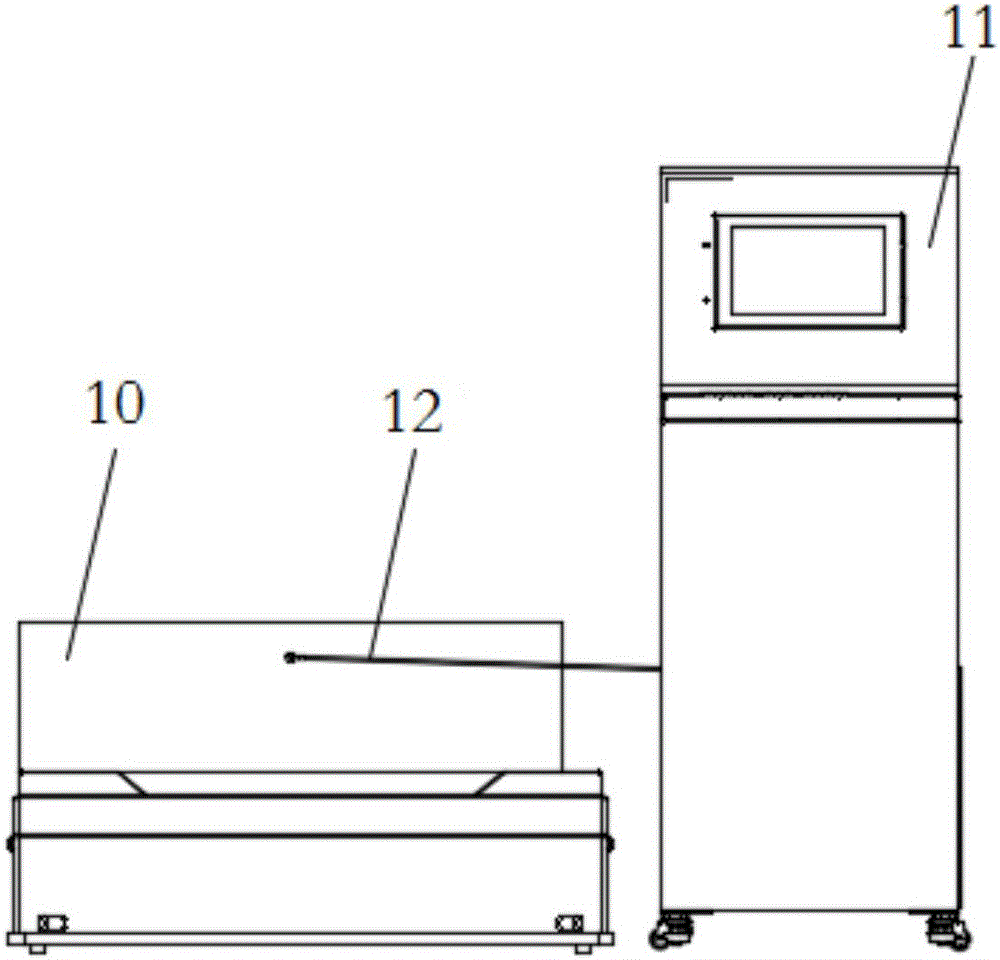

[0041] Step C: Input the barcode number of the battery pack to be tested, and then screw the gas pipe 12 of the airtight detection system 13 into the airtight test interface on the battery pack 10;

[0042] Step D: Click the "Start" button on the detection system to start testing the air tightness; the detection system first pumps air for 5 seconds, and when the air pressure in the battery pack 10 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com