Engine-bench-test air-feeding-and-discharging and air-leakage detection method

An engine bench and detection method technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc. The effect of R&D cost, increasing test accuracy and shortening test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061]A method for detecting intake and exhaust air leakage in an engine bench test. Before the test, it is first necessary to calibrate the flowmeter at the intake end of the engine bench test system, the exhaust gas measuring instrument at the exhaust end, and the fuel flow meter according to the environmental parameters of the test site. , to ensure the accuracy of the measurement data;

[0062] Then set standard deviation according to the requirements of test precision and test, in the present invention, described standard deviation is set to ± 0.03;

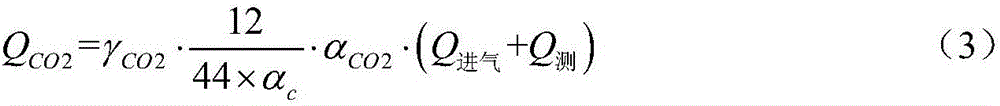

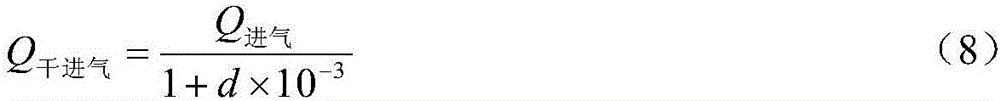

[0063] Use C balance to calculate the air leakage factor, and the air leakage factor is 1 under the standard state of no air leakage at all; the air leakage factor is the C content in the exhaust gas detected by the measuring instrument, and then the C balance is combined with the material that theoretically enters the engine The ratio of the estimated fuel consumption calculated by the total amount to the actual fuel consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com