Spiral flow fluidity testing mould

A technology for testing mold and fluidity, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problems of limited research and application scope, unable to reflect fluid fluidity, unable to eliminate experimental errors, etc., to eliminate experimental errors and mold structure. Compact, full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Under the same injection molding process conditions, the fluidity comparison test of PE-2909 and PP-T30S.

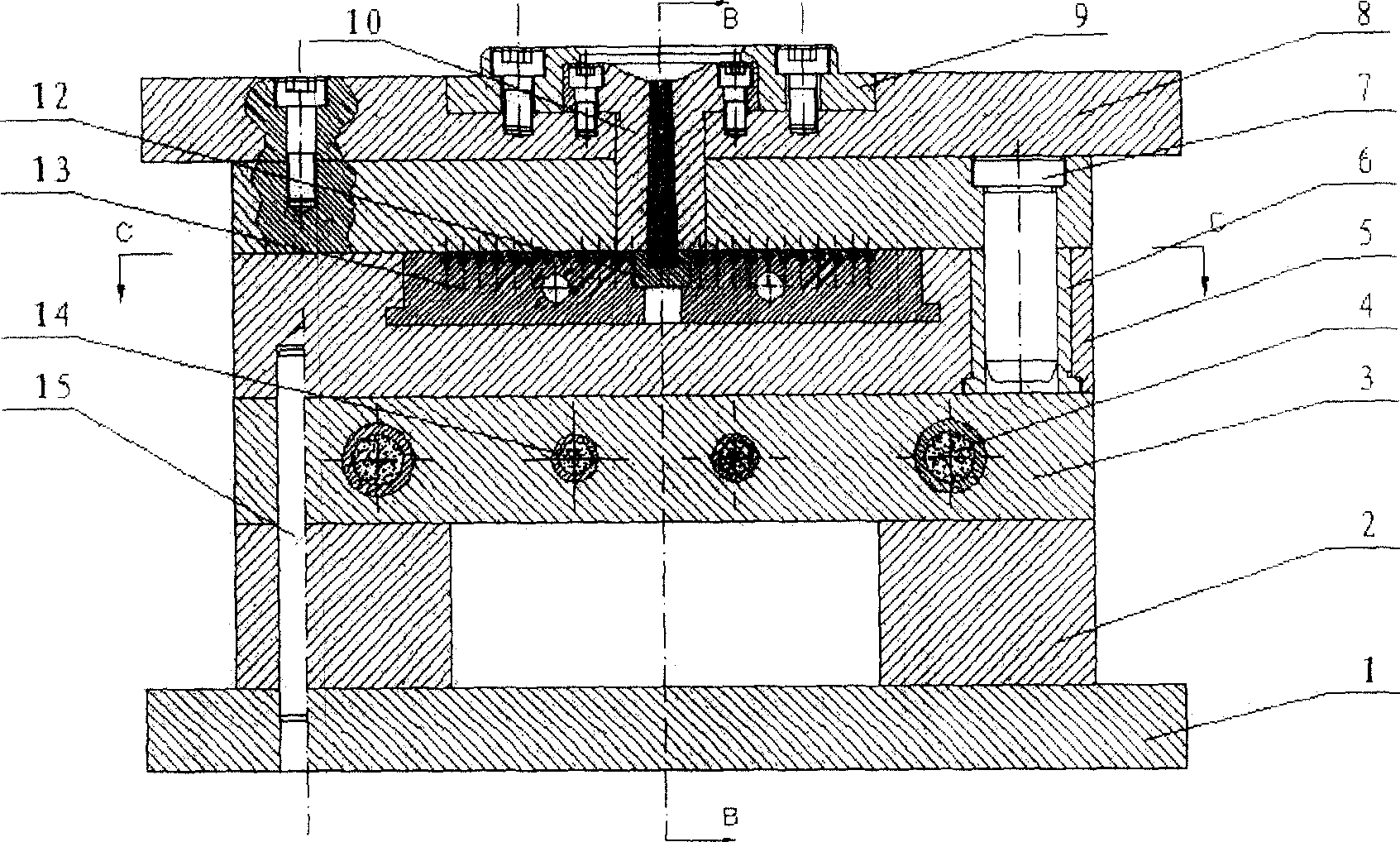

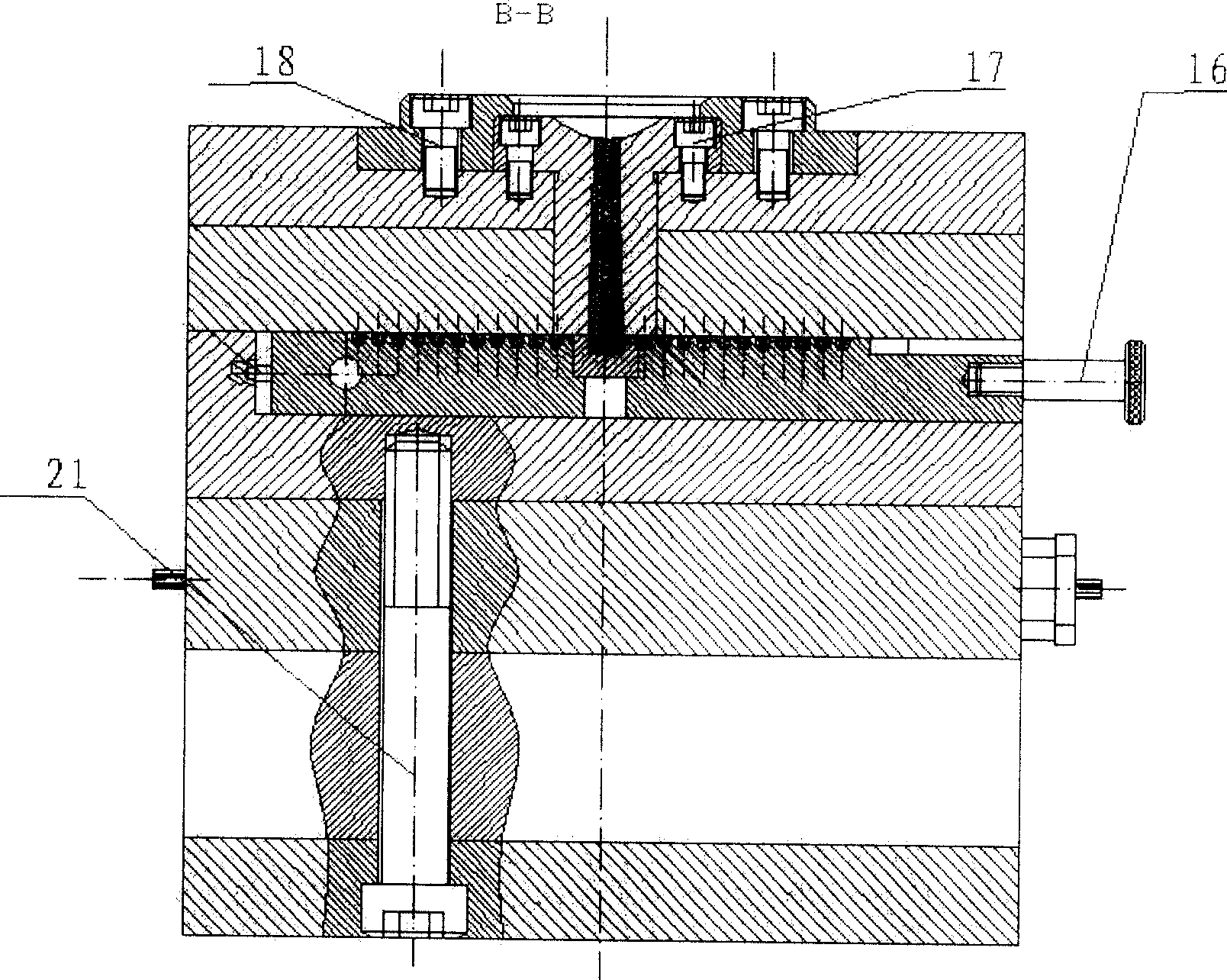

[0041] Stack the supporting block 2 and the heating plate 3 on the mold seat plate 1 in sequence, place the heating rod 4 and the heating rod 14 in the through hole of the heating plate 3, there is a stepped hole on the moving template 5, and the guide sleeve 6 is placed on the moving plate In the stepped hole of the template 5, there is an inlay guide rail in the movable template 5, and the movable template panel 13 is inserted into the movable template 5 through the guide rail for fastening connection. Installed on the movable mold panel through threaded holes, the mold seat plate 1, the support pad 2, the heating plate 3 equipped with heating rods, and the movable template 5 equipped with the movable mold panel and guide sleeve are positioned and connected by long pins 15 , fastened by long screws 21, the fixed template 8 equipped with the sprue bush...

Embodiment 2

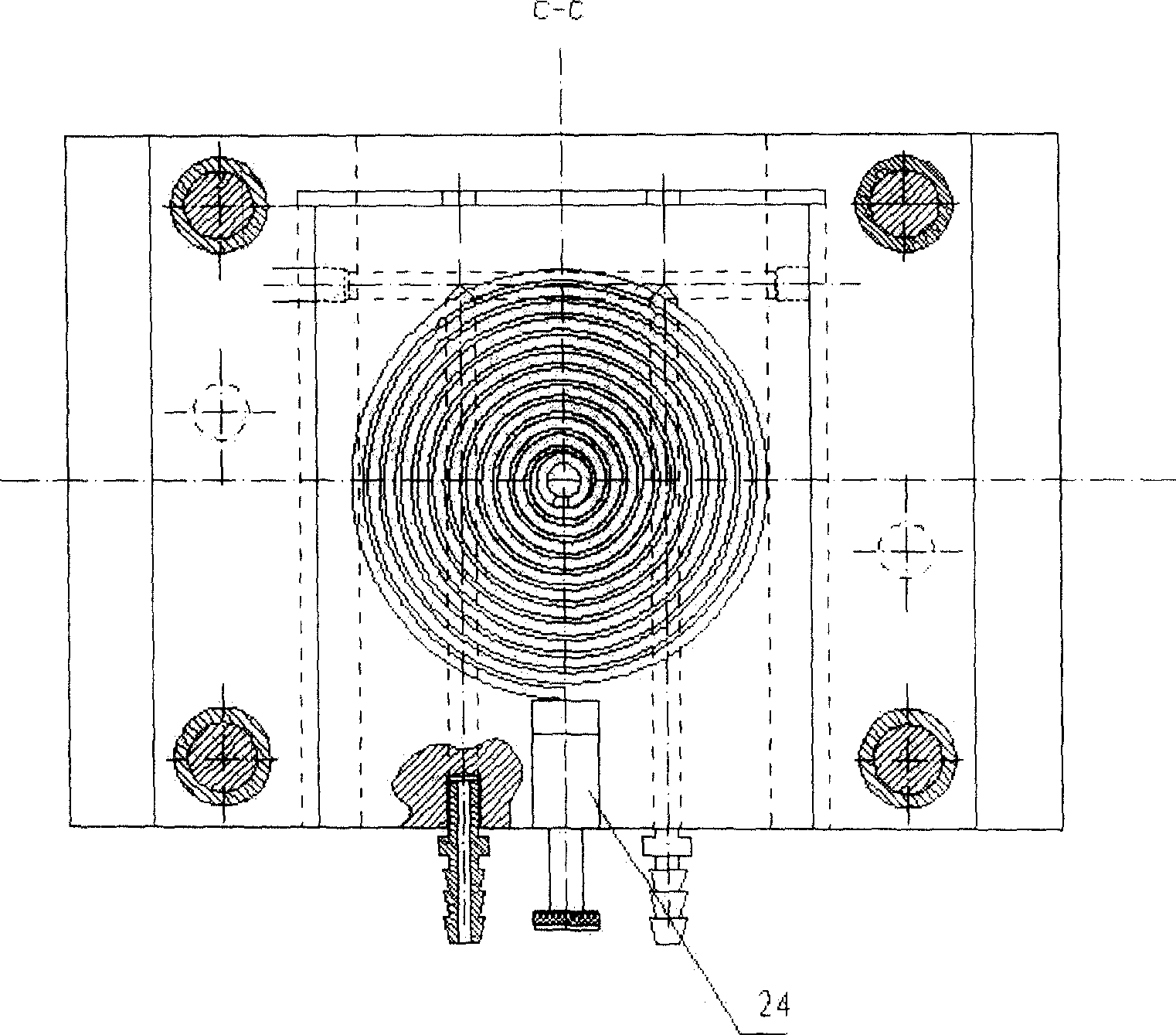

[0046] Example 2: Fluidity test of PP-T30S under different cavity cross-sectional shapes and different forms of helical cavity conditions

[0047] The test object is thermoplastic polypropylene (PP), the grade is T30S. The test content is to test the fluidity of the fluid under the conditions of sudden change of direction and smooth transition of the cavity and the fluidity of the fluid under the condition of different shapes of the cavity section. Under the same injection molding process conditions, the fluidity of PP-T30S was tested three times with three different cross-sectional shapes and spiral form movable templates. The injection molding process conditions are set as follows: melt temperature 220°C, injection pressure 80Mpa, injection rate 130g / s. After the experiment, the lengths of the helix samples were obtained: the helix length of the archimedes helix cavity with a semicircular section is 708mm, the helix length of the archimedes helix cavity with a rectangular se...

Embodiment 3

[0048] Example 3: Under the conditions of different injection molding processes and different rectangular gate sizes, W-Ni-Fe metal powder feed fluidity test and the relationship between fluidity, process parameters and gate size.

[0049] The test object is W-Ni-Fe metal powder feed (wt 98%, vol 58%), W:Ni:Fe=94:4:1 (weight percentage), binder is HDPE—PW—EVA—SA, The average particle size of the powder is 2~8μm, approximately spherical. The test content is the fluidity test of W-Ni-Fe metal powder feeding and the relationship between fluidity, process parameters and gate size under different injection molding processes and different rectangular gate sizes. Archimedes spiral moving formwork with semicircular section and 6 replaceable gate inserts in the form of rectangular side gates are adopted. Add W-Ni-Fe metal powder and HDPE-PW-EVA-SA binder into a mixer, melt and knead for 30 minutes, then cool and granulate to obtain feed for injection molding. Put the feed material in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com