Rapid technical analysis method of coal

An analytical method and industrial technology, applied in the field of industrial analysis and measurement of coal, to achieve the effect of shortening the total time, reducing the volume and improving the measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

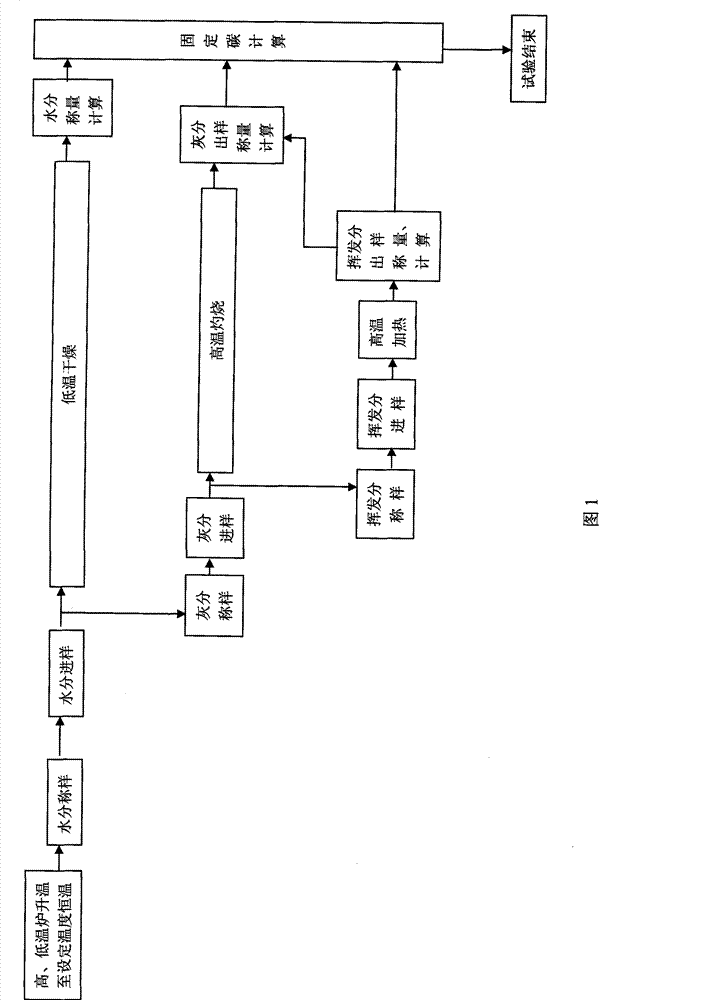

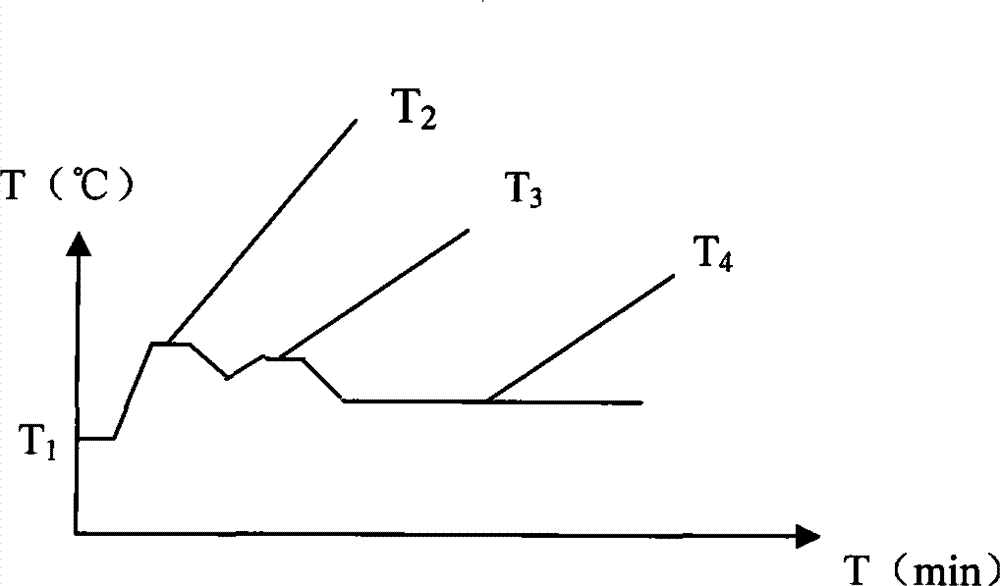

[0050] Specific embodiment 1: when moisture test time > ash content test time;

[0051] The test process is as follows: the instrument is turned on stably, reset, the high and low temperature furnaces are raised to the set temperature; 6 moisture air-dried coal samples are weighed in the normal temperature zone (the number in the scheme is for illustration only, not limited to this number), and the The sample mechanism is sent to the low-temperature furnace for drying; 6 ash air-dried coal samples are weighed in the normal temperature zone, and sent to the high-temperature furnace for burning through the sample feeding mechanism, and the damper is opened at this time; the volatile air-dried coal samples are weighed in the normal temperature zone 6 samples, close the damper of the high-temperature furnace; send the volatile air-dried coal samples into the high-temperature furnace for heating; at this time, there are 6 ash air-dried coal samples and 6 volatile air-dried coal samp...

specific Embodiment 2

[0052] Specific embodiment 2: when ash content test time>moisture test time;

[0053] The test process is as follows: the instrument is turned on stably, reset, the high and low temperature furnaces are raised to the set temperature; 6 ash air-dried coal samples are weighed in the normal temperature zone (the number of examples in the scheme is for illustration only, not limited to this number); at this time The damper of the high-temperature furnace is opened; the ash air-dried coal sample is sent to the high-temperature furnace by the sampling mechanism for burning; 6 moisture air-dried coal samples are weighed in the normal temperature zone, and sent to the low-temperature furnace for drying through the sampling mechanism; Weigh 6 volatile air-dried coal samples; close the high-temperature furnace air door; send volatile air-dried coal samples into the high-temperature furnace for heating; at this time, there are 6 ash air-dried coal samples and 6 ash air-dried coal samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com