Improved oblique-Y-shaped groove welding crack sensitivity test sample and manufacturing method thereof

A crack sensitivity and groove welding technology, which is applied in the field of metal material welding, can solve the problems that affect the accurate evaluation of material welding crack sensitivity, the root gap is difficult to effectively guarantee, and the impact of crack sensitivity, etc., to reduce human and financial resources consumption, Efficiency and quality improvement, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

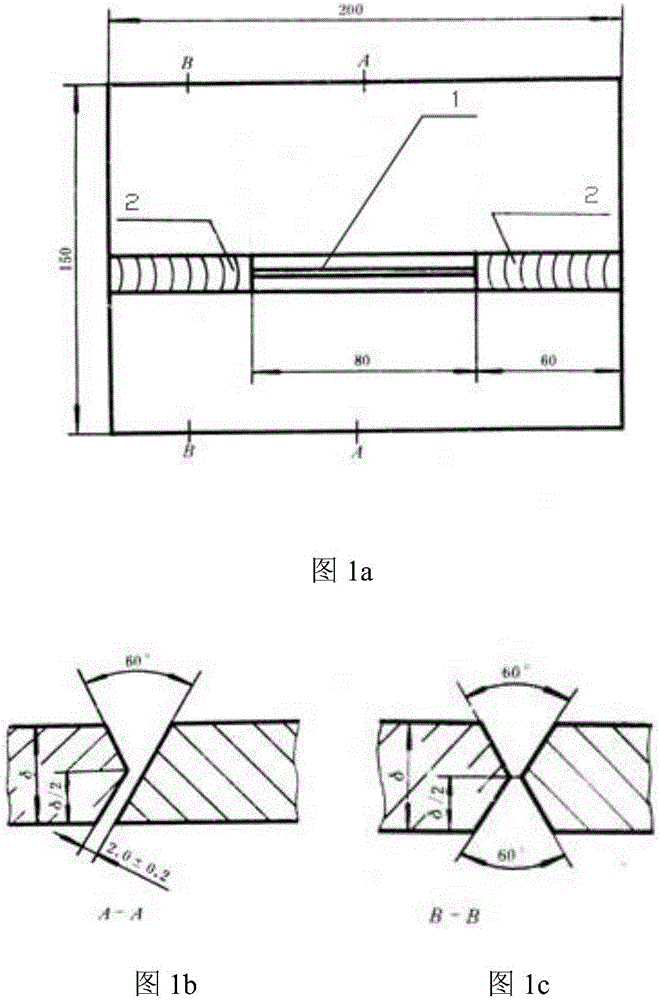

[0026] Embodiment 1 traditional mechanical method processing

[0027] 1) Mark the line to determine the position of the weld bevel in the processing test;

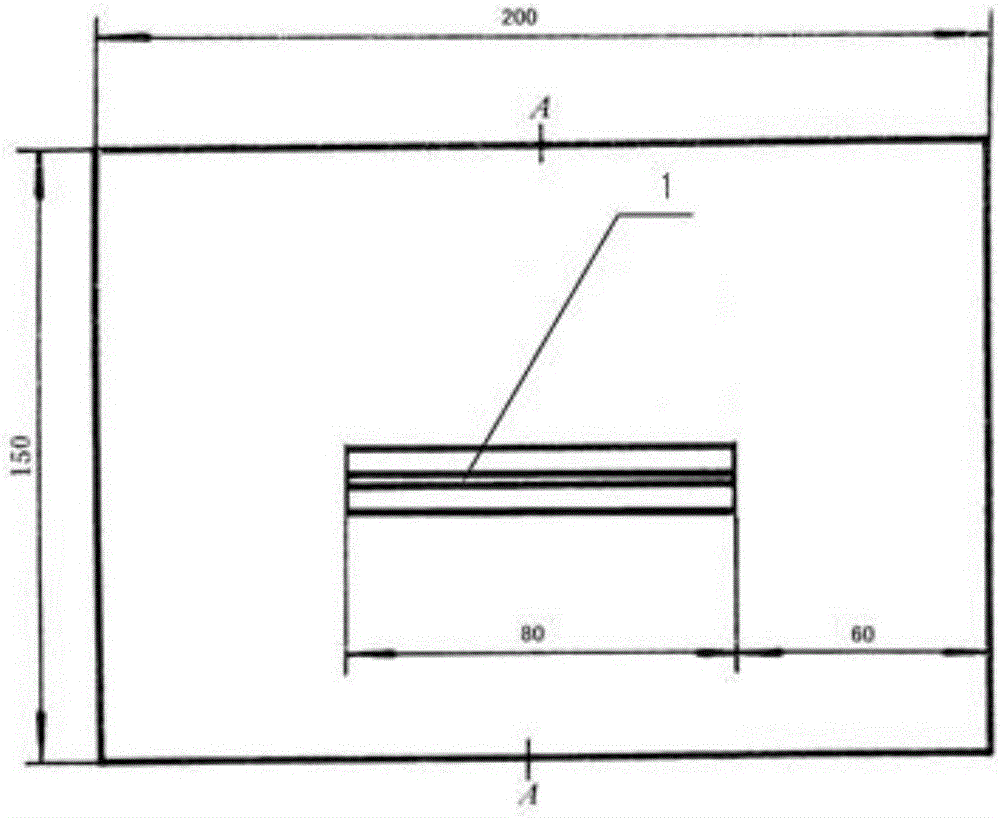

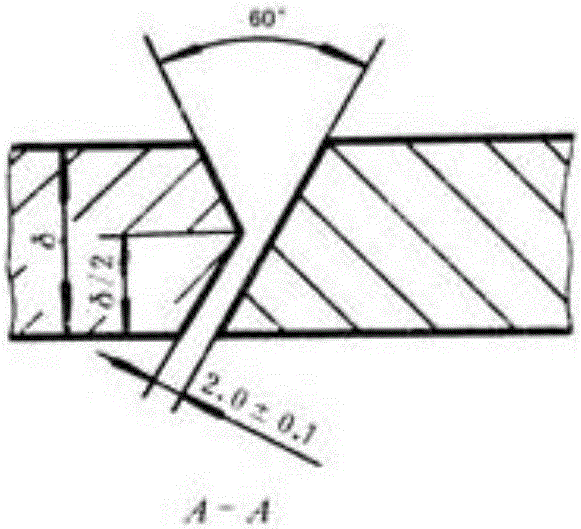

[0028] 2) First use a 2mm end mill to process a rectangular groove with a width of 2mm on the upper half of the specimen along the thickness direction, such as Figure 4 a; then the test piece is horizontally inclined by 30°, and a groove surface is processed on one side of the rectangular groove with the end mill, and the bottom edge of the groove surface coincides with the axial bottom edge of the rectangular groove, such as Figure 4 b; After completion, use the same method to process the groove surface on the other side to obtain a V-shaped groove, such as Figure 4 c;

[0029] 3) EDM is used to process the gap groove in the lower half of the test piece along the thickness direction, or the test piece is tilted 30° horizontally and a 2mm end mill is used to process the gap groove in the lower half of the test piece a...

Embodiment 2

[0031] Embodiment 2 CNC machine tool processing

[0032] 1) On the CNC machine tool, select the processing mode of small cutter head, small feed rate, and high-speed rotation, and formulate the program for processing the test weld bevel according to the operation steps in Example 1;

[0033] 2) Clamping the specimen;

[0034] 3) Process the test piece according to the program;

[0035] 4) Grind the irregularities and burrs of the corners by manual rubbing and grinding, and check to ensure the dimensional accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Weld length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com