Multichannel power correction control device and method

A time-controlled, multi-channel technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problem of inability to achieve multi-print head power calibration time control, etc., to improve accuracy and real-time performance, Improve real-time performance and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

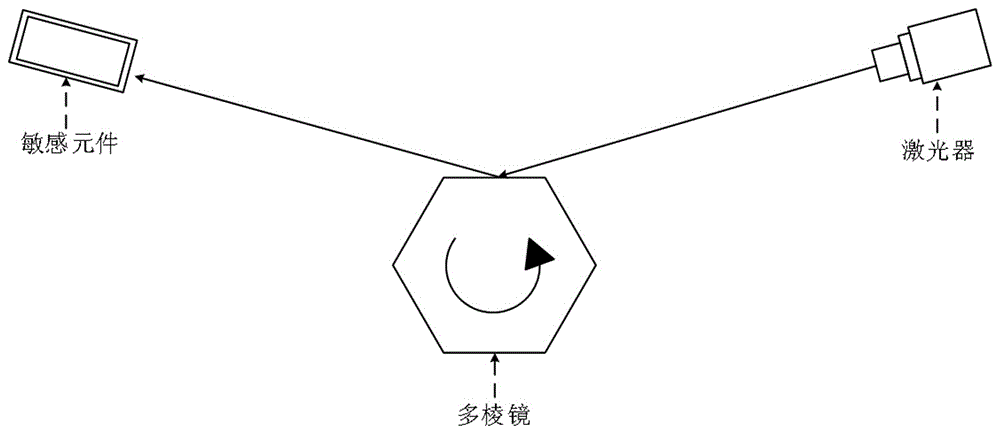

[0023] The invention mainly aims at multi-channel power calibration time control, and proposes a real-time, efficient and accurate control method which saves hardware resources.

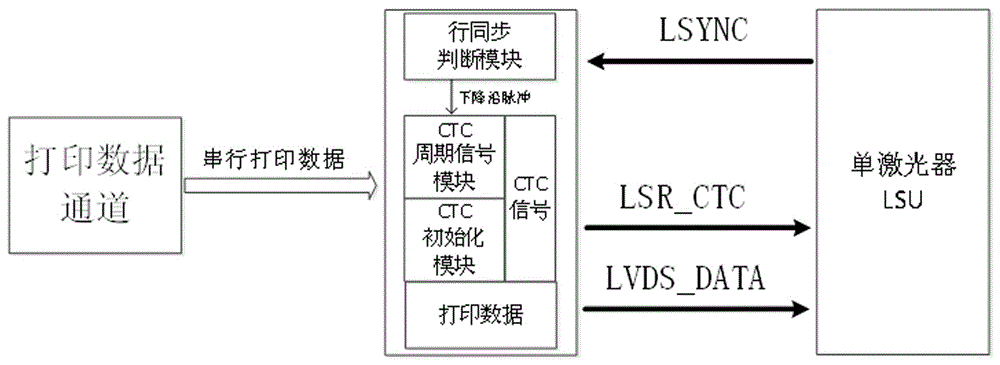

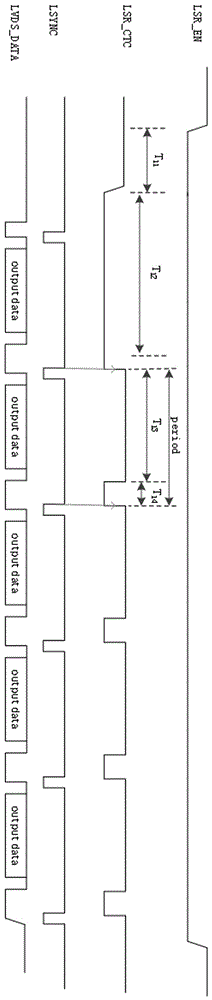

[0024] Such as Figure 4 As shown, the multi-channel power calibration time control unit of the present invention ( Figure 4 shown in the dashed box), including LSU enabling and line synchronization processing module, CTC1 signal module, n-1 signal splitting control module, n-1 signal aliasing generator module, and n-1 automatic cycle dialing control module.

[0025] The LSU enabling and line synchronization processing module includes an LSU enabling unit, a line synchronization signal detection unit, a configuration information unit and an edge pulse generator.

[0026] The enabling of the LSU enabling unit is the starting point for all subsequent modules to work. The configuration informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com