Transparent conductive film

A technology of transparent conductivity and transparent conductor layer, which is applied in the direction of conductive layer on insulating carrier, electrical digital data processing, instruments, etc., and can solve problems such as defects, reduced curvature, and reduced hardness of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

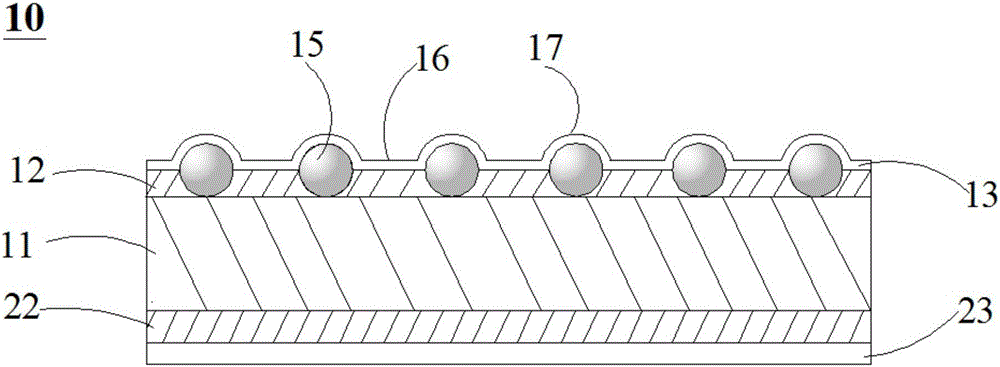

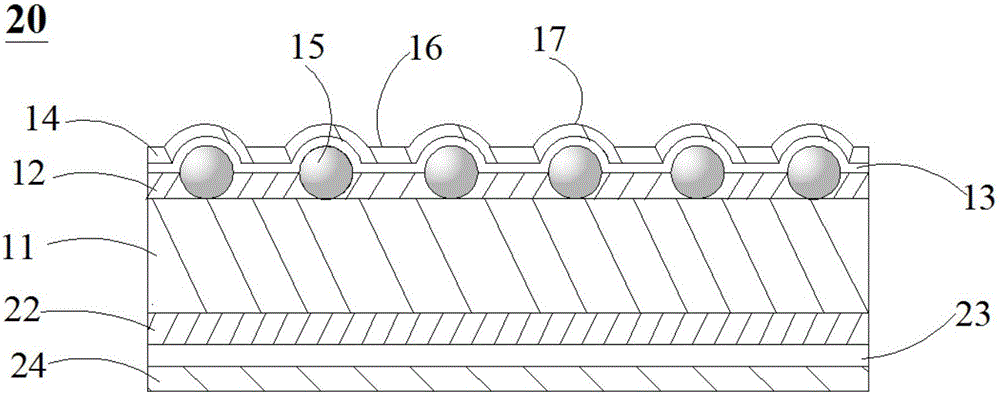

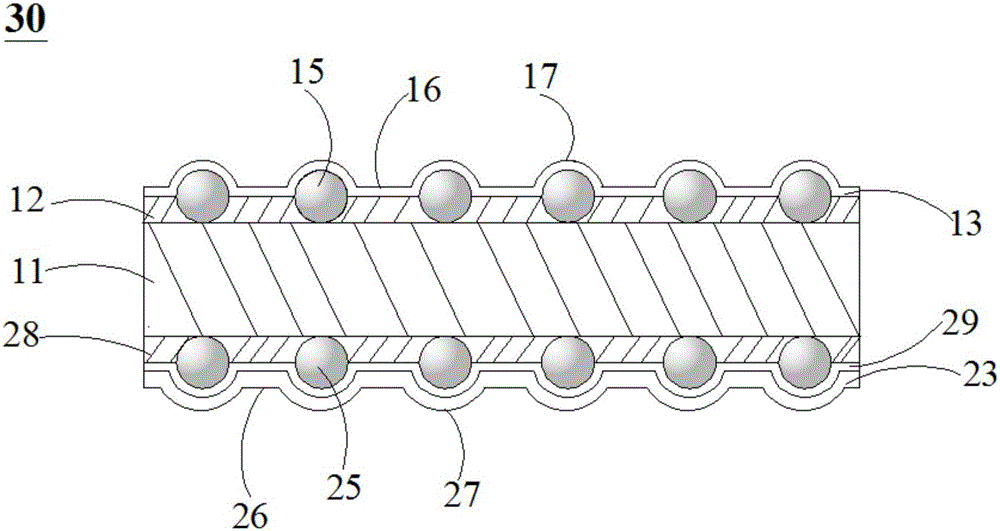

[0025] The transparent conductive film provided by the invention can be used in display terminals requiring capacitive touch panels, such as mobile phones and tablet computers.

[0026] like figure 1 As shown, the transparent conductive film 10 in the first embodiment of the present invention has a substrate 11, and the substrate 11 includes a first surface (ie figure 1 The upper surface of the middle substrate 11) and the second surface (i.e. figure 1 the lower surface of the middle substrate 11). The first composite layer 12 and the first transparent conductor layer 13 are sequentially arranged on the first surface of the substrate 11 , and the second composite layer 22 and the second transparent conductor layer 23 are sequentially arranged on the second surface of the substrate 11 .

[0027] The substrate 11 may be formed by an amorphous polymer film, and the material of the film may be amorphous polycycloolefin, polycarbonate or polyimide. A first composite layer 12 con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com