Polypropylene thin film capacitor applicable to surface mounting

A polypropylene film and surface mounting technology, applied in the field of capacitors, can solve the problems that affect the performance of polypropylene film capacitors, the potting material cannot effectively absorb heat, and cannot be mounted on the surface, so as to prevent delamination, prevent separation, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

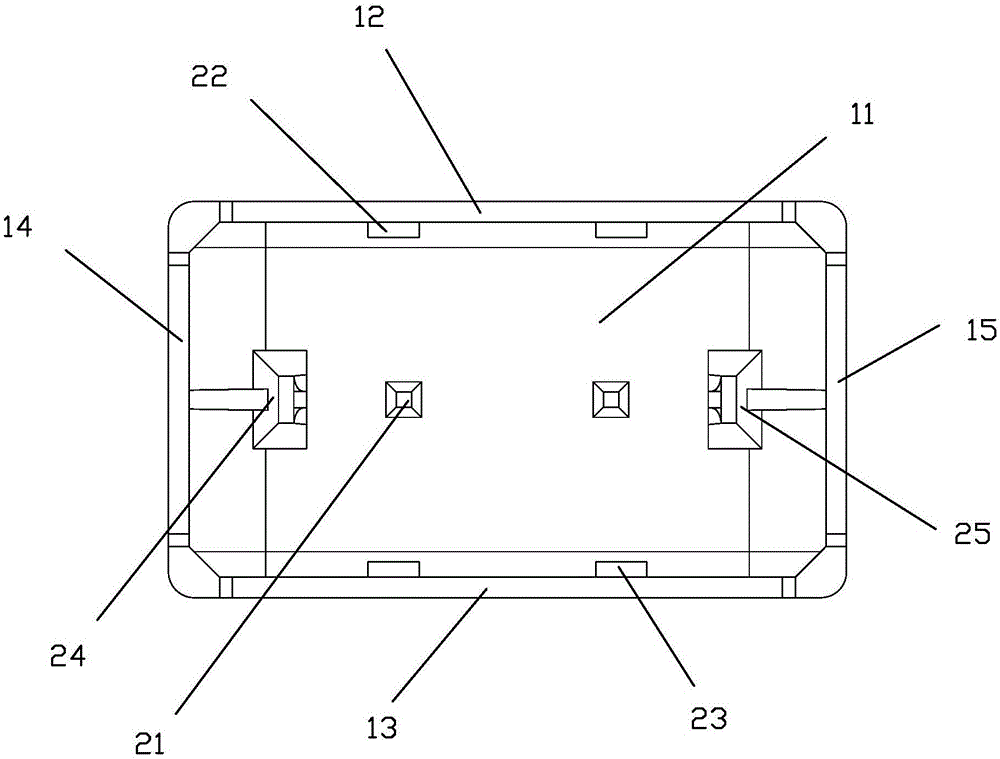

[0020] see figure 1 Shown, a kind of polypropylene film capacitor that is used for surface mounting of the present invention comprises polypropylene film capacitor core, plastic housing 1 and is filled in the potting body between polypropylene film capacitor core and housing; So The potting body is formed after potting with a prefabricated potting compound; the prefabricated potting compound is formed by adding 50% organic crystalline engineering plastic powder or granules based on the conventional potting compound to the conventional potting compound, It is obtained after being evenly stirred by a mixer, so as to realize temperature clamping by using the heat entropy value of organic crystalline engineering plastics, and fully absorb the heat transmitted to the core at the moment of reflow soldering;

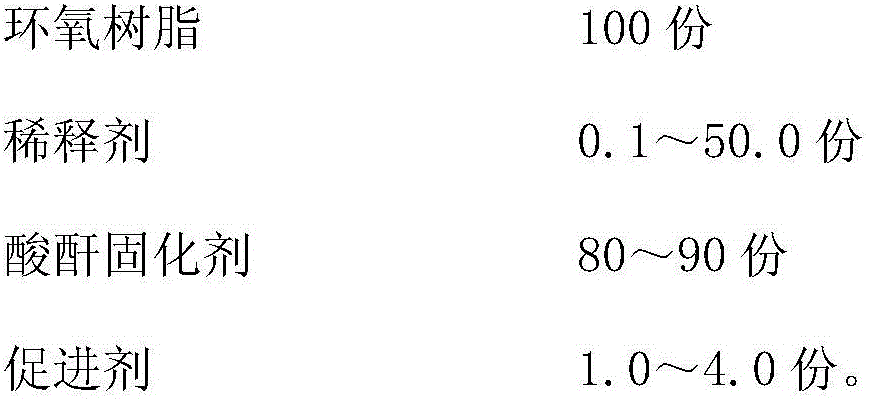

[0021] The conventional potting compound includes the following components and parts by weight:

[0022]

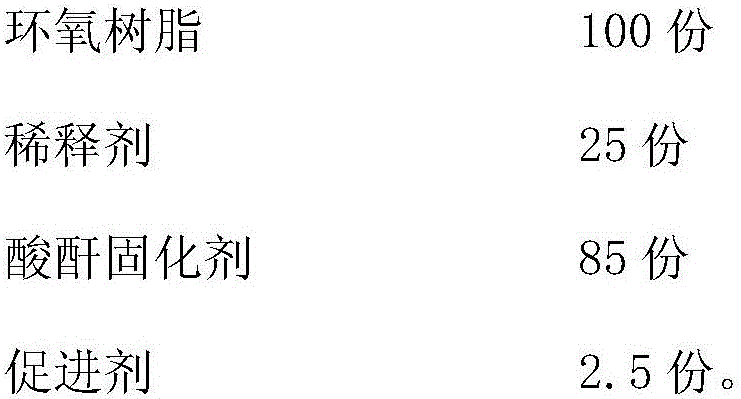

[0023] Further, the prefabricated potting compound also includes ...

Embodiment 2

[0033] A kind of polypropylene film capacitor that is used for surface mounting of the present invention, differs from embodiment 1 in that, described prefabricated potting compound is to add 10% based on conventional potting compound in conventional potting compound Organic crystalline engineering plastic powder or granules.

Embodiment 3

[0035] A polypropylene film capacitor for surface mounting of the present invention differs from Embodiment 1 in that the prefabricated potting compound is added with 25% of the conventional potting compound as the base in the conventional potting compound Organic crystalline engineering plastic powder or granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com