Silicon solar thin-film cell based on double-layer micro-nano two-dimensional multi-tooth resonant grating

A technology of solar thin film and grating, applied in the field of optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

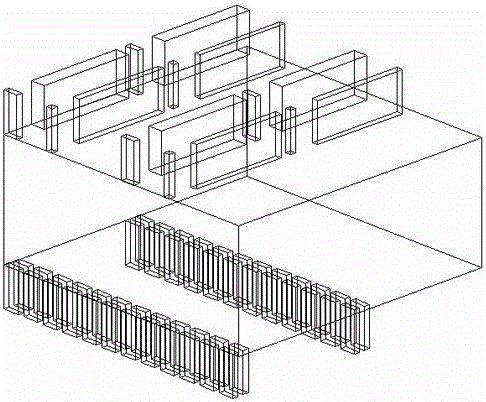

[0031] Describe in detail below in conjunction with accompanying drawing:

[0032] 1. Overall

[0033] Such as figure 1 As shown, the upper and lower surfaces of the silicon active layer of the solar thin film cell are provided with a micro-nano two-dimensional multi-tooth resonant grating that changes periodically along the X and Y axes, and there are two grating teeth of silicon material in each period, and two A material is a grating groove of air, and the thickness of the grating layer is along the Z-axis direction.

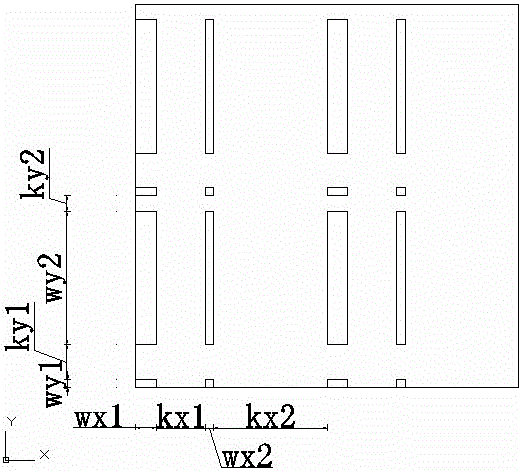

[0034] 2. Micro-nano two-dimensional multi-tooth resonant grating on the upper surface of the silicon active layer:

[0035]The grating period along the X axis is 1200 nm (T x1 =1200nm), there are two grating teeth of silicon material in each period, and their widths are respectively, wx 11 = 130 nm, wx 12 =54 nanometers; and two grating grooves made of air, whose widths are respectively, kx 11 =306 nm, kx 12 =710nm;

[0036] The grating period along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com