White light-emitting device and manufacturing method thereof

A light-emitting device, white light technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven light emission, low light-emitting purity, weak reflection of inorganic phosphors, etc., and achieve the effect of high light-purity and uniform light-emitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

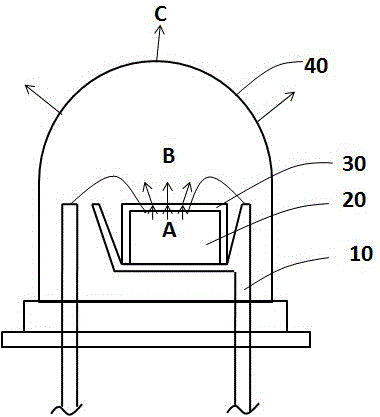

[0025] See attached figure 1 , a schematic cross-sectional view of a white light emitting device according to an embodiment of the present invention. The white light emitting device provided by the present invention includes a support 10, a light-emitting diode 20 on the support 10, an organic semiconductor polymer light conversion layer 30, and a transparent encapsulation structure 40 for protecting and fixing the light-emitting diode 20. The light conversion layer 30 absorbs The first light A emitted by the light emitting diode 20 is converted into a second light B different from the first light A, and the first light A and the second light B are mixed in the transparent encapsulation structure 40 to form white light C. Wherein, the material of the transparent encapsulation structure 40 is an encapsulation resin; the material of the organic semiconducting polymer light conversion layer 30 is a thiophene polymer, especially a high isotactic poly-3-hexylthiophene. In some embo...

Embodiment 2

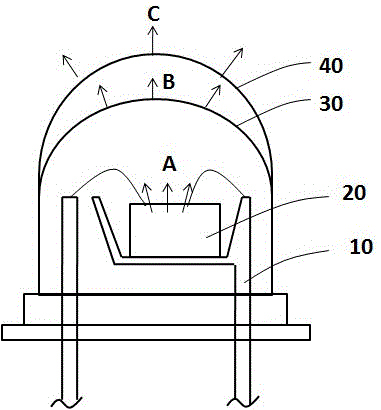

[0034] The difference between this embodiment and Embodiment 1 is that the organic semiconducting polymer light conversion layer 30 is disposed in the transparent encapsulation structure 40, and the transparent encapsulation structure 40 with the built-in organic semiconducting polymer light conversion layer 30 covers the light emitting diode 20 to protect and Fix the light emitting diode 20 .

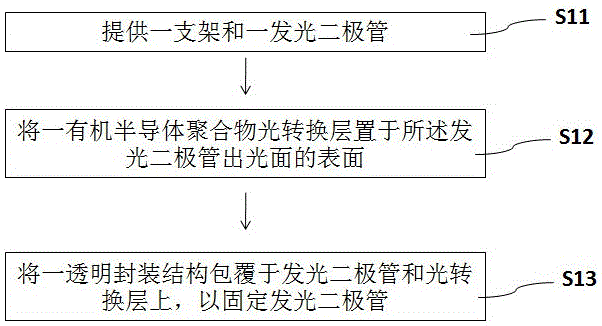

[0035] The method for making the above-mentioned light-emitting diodes in this embodiment specifically includes the following steps:

[0036] S21, providing a bracket 10 and a light emitting diode 20;

[0037] S22, arranging an organic semiconductor polymer light conversion layer 30 in a transparent encapsulation structure 40;

[0038] S23 , covering the light-emitting diode 20 with the transparent encapsulation structure 40 built with the organic semiconductor polymer light conversion layer 30 , so as to protect and fix the light-emitting diode 20 .

[0039] Wherein, the organic sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com