Polycyclic aromatic hydrocarbon organic compound, composition and light-emitting device

A technology of organic compounds and condensed aromatic hydrocarbons, applied in the field of optoelectronic materials, can solve the problems of insufficient color coordinates, insufficient rigidity, and structural distortion of light-emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Embodiment 1 compound T1 and preparation method thereof

[0113] (1) Preparation of intermediate M1:

[0114] Add 6mmol phenylboronic acid, 5mmol 1,8-dichloroanthracene, 0.2mmol tetrakistriphenylphosphopalladium Pd(PPh 3 ) 4 , 7.5mmol potassium carbonate K 2 CO 3 , add a stirring magnet, carry out vacuuming and nitrogen replacement operation, repeat three times, make the reaction bottle in a nitrogen atmosphere, add mixed solvent tetrahydrofuran THF / deionized water (V / V=5:4) 50ml, reflux reaction at 70°C for 24h; After cooling to room temperature, the reaction solution was poured into water, extracted 3 times with dichloromethane, and then washed with anhydrous MgSO 4 Dry, filter, and remove the solvent by rotary evaporation, separate and purify with a silica gel chromatography column, use n-hexane / dichloromethane as eluent, and remove the solvent by rotary evaporation to obtain product M1 with a yield of 86%, using HPLC-MS and 1 H NMR to identify the compound, for...

Embodiment 2

[0128] Embodiment 2 compound T4 and preparation method thereof

[0129] (1) Preparation of intermediate M5

[0130] Add 6mmol (2,6-dichlorophenyl)boronic acid, 5mmol 9,10-dibromoanthracene, 0.2mmol tetrakistriphenylphosphopalladium Pd(PPh 3 ) 4 , 7.5mmol potassium carbonate K 2 CO 3 , add a stirring magnet, carry out vacuuming and nitrogen replacement operation, repeat three times, make the reaction bottle in a nitrogen atmosphere, add mixed solvent tetrahydrofuran THF / deionized water (V / V=5:4) 50ml, reflux reaction at 70°C for 24h; After cooling to room temperature, the reaction solution was poured into water, extracted 3 times with dichloromethane, and then washed with anhydrous MgSO 4 Drying, filtration, rotary evaporation to remove solvent, separation and purification with silica gel column, using n-hexane / dichloromethane as eluent, rotary evaporation to remove solvent to obtain product M5, yield 76%, using HPLC-MS and 1 H NMR to identify the compound, formula C 20...

Embodiment 3

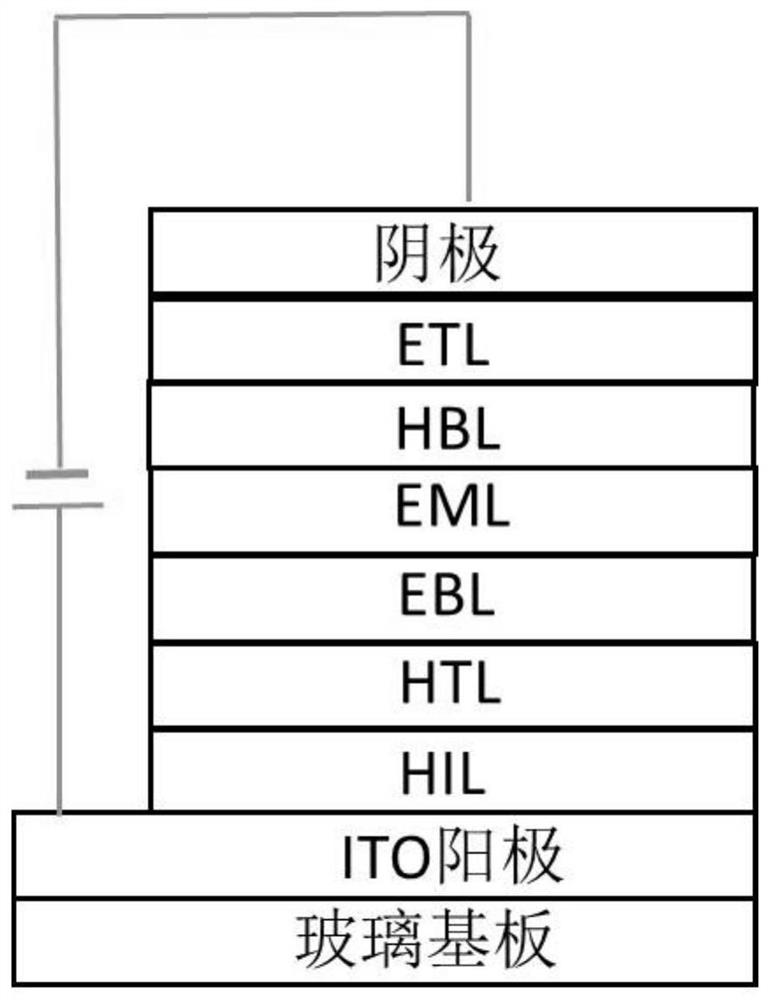

[0141] Example 3, organic light-emitting diode components and their preparation

[0142] This embodiment provides an organic light emitting diode component, which includes: a first electrode, a hole injection layer formed on the first electrode, a hole transport layer formed on the hole injection layer, and An electron blocking layer is formed on the hole transport layer, a light emitting layer is formed on the electron blocking layer, a hole blocking layer is formed on the light emitting layer, an electron transport layer is formed on the hole blocking layer, on the An electron injection layer formed on the electron transport layer, a second electrode covering the electron injection layer;

[0143] Wherein, the light-emitting layer comprises the compound T1 of the above-mentioned Example 1.

[0144] The preparation method of the organic light emitting diode component comprises the following steps:

[0145] (1) First, clean the ITO substrate in the following order: 5% KOH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com