Waste heat recovery system for fuel battery trolley car based on thermoelectric power generation

A waste heat recovery system and fuel cell technology, applied in fuel cell heat exchange, fuel cell, battery/fuel cell control devices, etc., can solve the problems of inability to fuel cell secondary power generation, low energy utilization rate, etc., and achieve light weight , the effect of high power level and large total heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

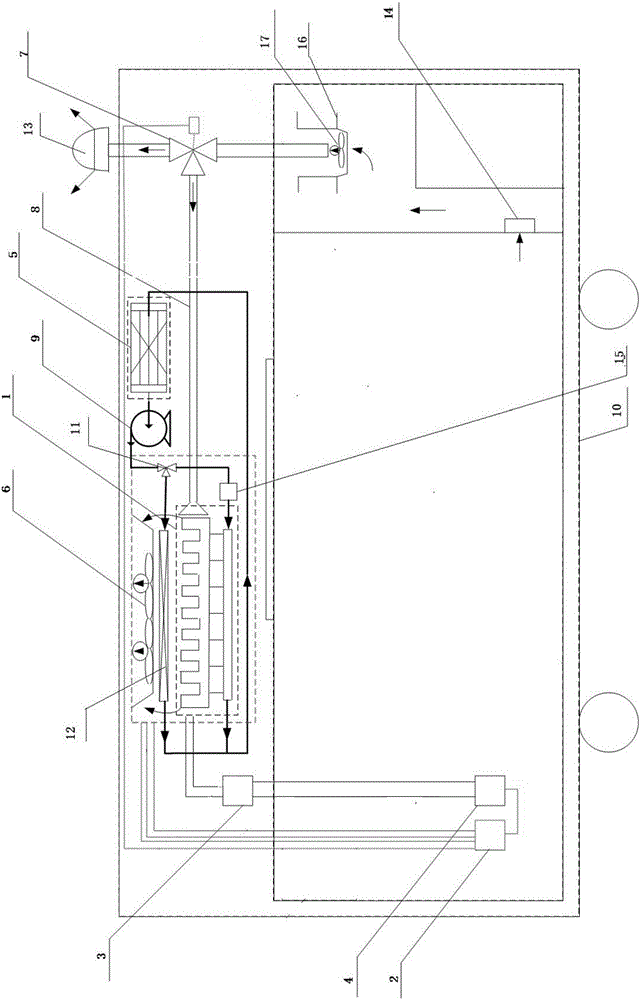

[0036] In this example, see figure 1 As shown, the present invention proposes a fuel cell tram waste heat recovery system based on thermoelectric power generation, which includes a thermoelectric power generation main module 1, a main controller 2, a voltage stabilizing module 3, a power consumption module 4 and a fuel cell 5;

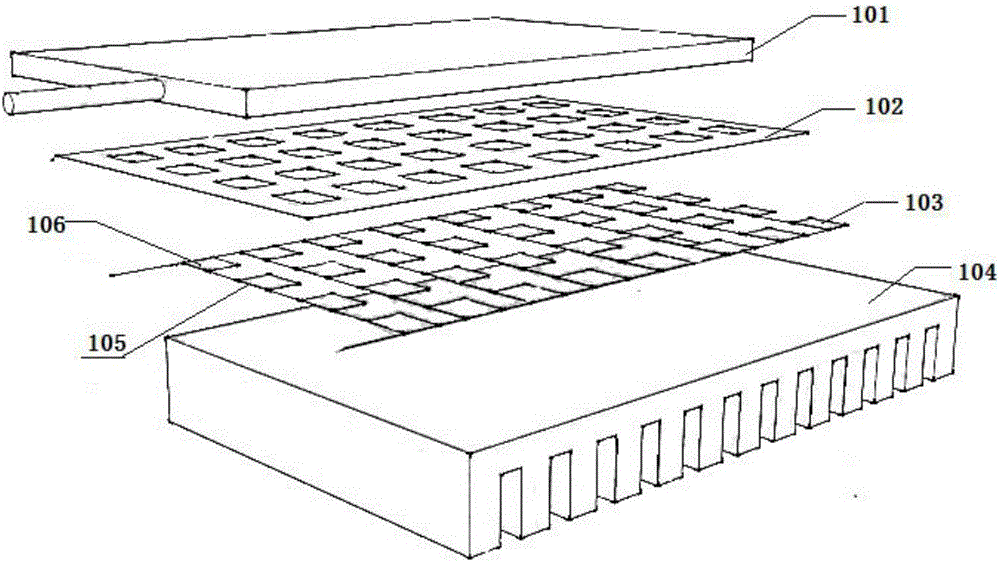

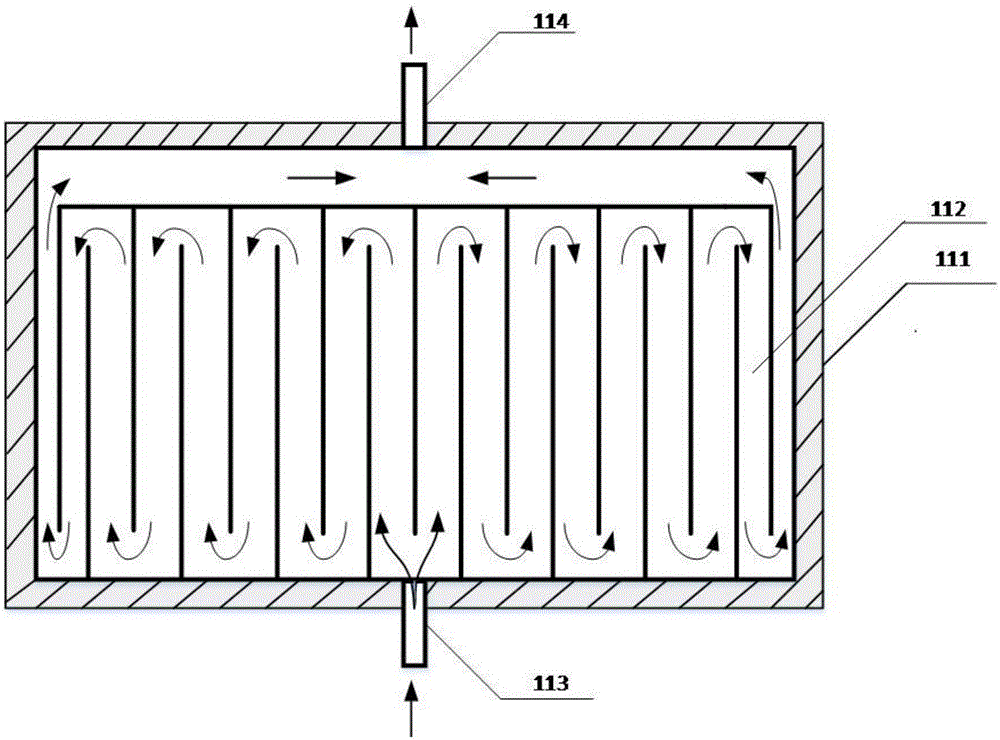

[0037] The thermoelectric power generation main module 1 is installed on the top of the compartment 10, and the water inlet 113 of the hot end water tank 101 of the thermoelectric power generation main module 1 is connected to the fuel cell 5 coolant outlet sleeve, and a circulating water pump is arranged at the coolant outlet sleeve 9. The water outlet 114 of the hot end water tank 101 of the thermoelectric power generation main module 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com