A new type of power electronic module

A technology of power electronic modules and busbar terminals, which is applied in the direction of circuits, electrical components, and electric solid devices, and can solve problems such as dynamic and static unevenness of parallel devices, large proportion of inductive reactance components, and unevenness of parallel circuits. , to eliminate uneven branch inductance, achieve branch uniformity, and relieve heat dissipation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Refer to attached picture.

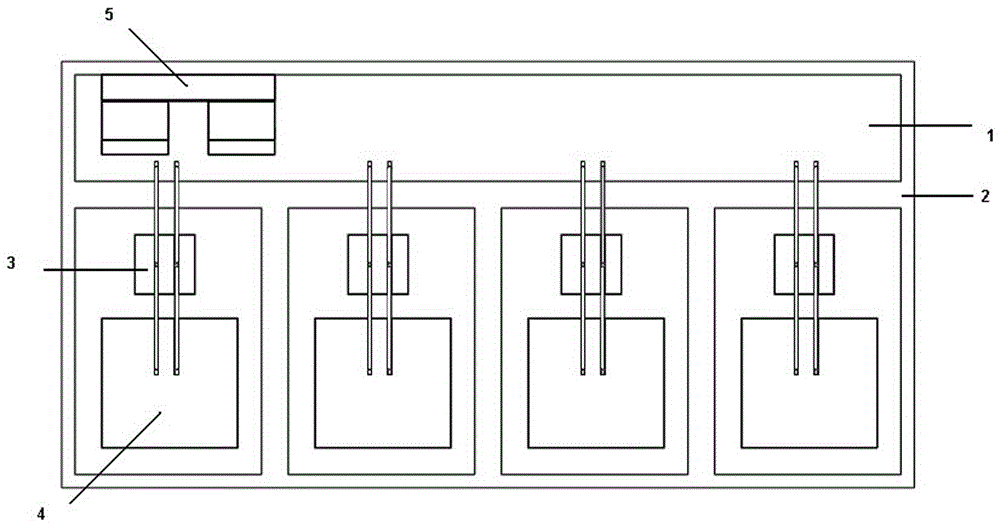

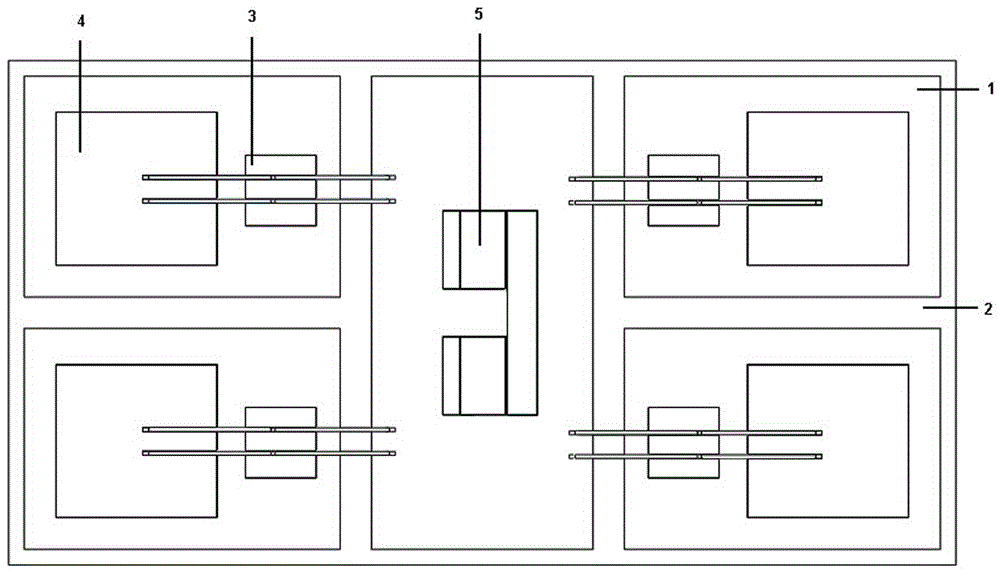

[0017] The structure of the present invention includes an upper copper layer 1, a ceramic layer 2, a diode chip 3, a power device chip 4, and a busbar terminal 5. The module also includes 3 or more power device chips connected in parallel, and a busbar terminal 5 Placed at the center of all the above parallel chips.

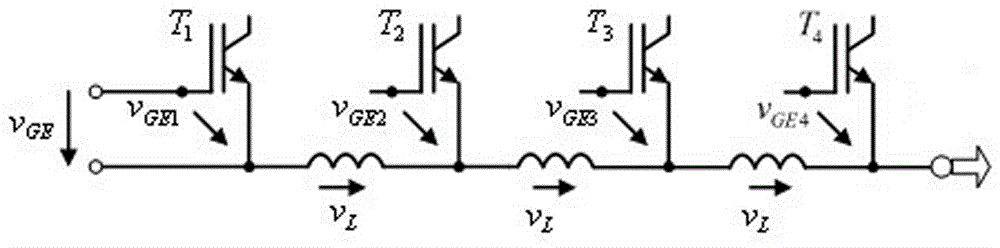

[0018] In the traditional sense, the pieces of copper on the top layer of the DBC board are called "islands". Each island plays the role of flowing current. The islands can be welded with devices or busbar bracket terminals, and the islands are connected by aluminum wires. connect. The traditional DBC layout is attached figure 1 As shown, the equivalent circuit is as figure 2 . from figure 2 It can be seen that due to this structure, there is a distributed inductance between the "ground" and the ground of the parallel device, and these distributed inductances are connected to the ports in series, resulting in inconsisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com