A processing method of planar waveguide cts array antenna

An array antenna and planar waveguide technology, which is applied in the direction of manufacturing antenna array devices, antennas, antenna arrays, etc., can solve the problems of serious magnetic flux leakage, use restrictions, and magnetic flux leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: a kind of processing method of planar waveguide CTS array antenna, comprises the following steps:

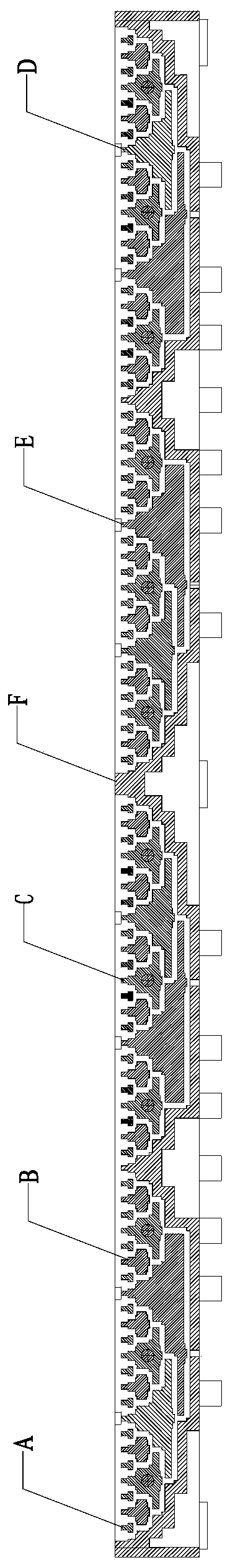

[0031]① Divide the planar waveguide CTS array antenna to be processed into N+1 independent layers according to the following rules, N is the number of series of waveguide "E-T" branches: located above the "E-T" branch of the Nth waveguide and connected to the Nth waveguide " The part where the upper end face of the "E-T" branch intersects is taken as the first independent layer, and the part that is located above the N-1th waveguide "E-T" branch and intersects with the upper end face of the N-1st waveguide "E-T" branch is the second Independent layer, the part located above the "E-T" branch of the N-2 waveguide and intersecting with the upper end face of the N-2 waveguide "E-T" branch is the third independent layer, and so on, located in the first-level waveguide " The part above the "E-T" branch and intersecting the upper end surface of the first-stage wa...

Embodiment 2

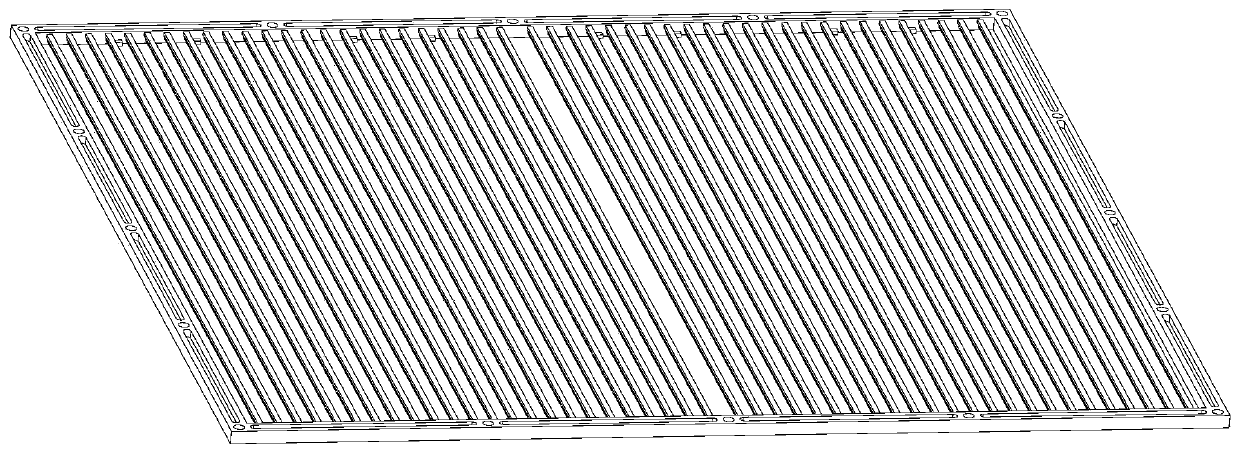

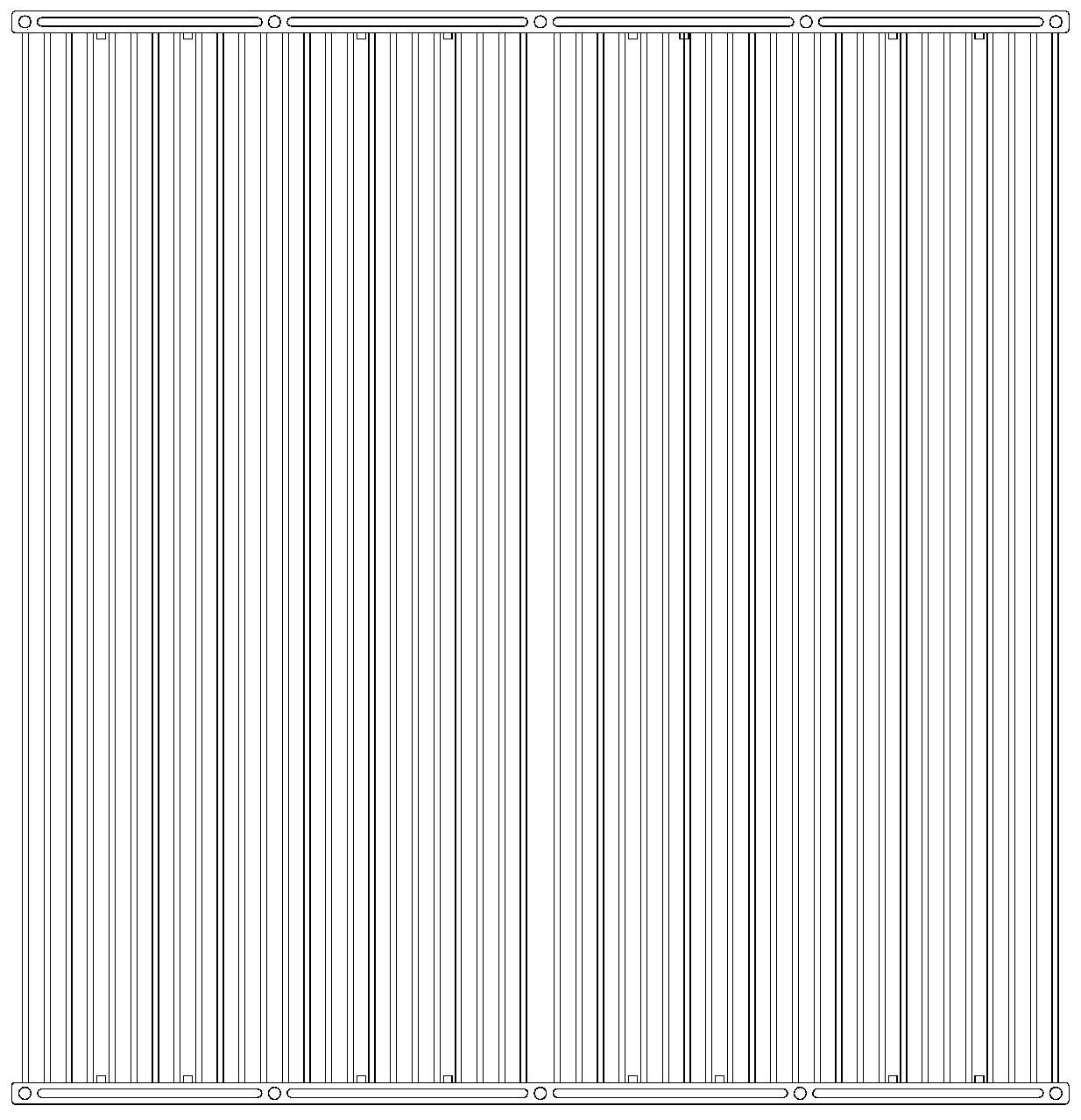

[0038] Embodiment 2: As shown in the figure, a processing method of a slab waveguide CTS array antenna, the number of stages of the "E-T" branch of the slab waveguide CTS array antenna waveguide is 5, including the following steps:

[0039] ① The planar waveguide CTS array antenna to be processed is divided into 6 independent layers according to the following rules: the part located above the "E-T" branch of the fifth-level waveguide and intersecting with the upper end surface of the fifth-level waveguide "E-T" branch is taken as the first The independent layer A is located above the "E-T" branch of the fourth-level waveguide and intersects with the upper end face of the fourth-level waveguide "E-T" branch as the second independent layer B, located above the "E-T" branch of the third-level waveguide and connected to the The intersecting part of the upper end surface of the "E-T" branch of the third-level waveguide is regarded as the third independent layer C, and the part locat...

Embodiment 3

[0044] Embodiment 3: As shown in the figure, a processing method of a slab waveguide CTS array antenna, the number of stages of the "E-T" branch of the slab waveguide CTS array antenna waveguide is 5, including the following steps:

[0045] ① The planar waveguide CTS array antenna to be processed is divided into 6 independent layers according to the following rules: the part located above the "E-T" branch of the fifth-level waveguide and intersecting with the upper end surface of the fifth-level waveguide "E-T" branch is taken as the first The independent layer A is located above the "E-T" branch of the fourth-level waveguide and intersects with the upper end face of the fourth-level waveguide "E-T" branch as the second independent layer B, located above the "E-T" branch of the third-level waveguide and connected to the The intersecting part of the upper end surface of the "E-T" branch of the third-level waveguide is regarded as the third independent layer C, and the part locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com