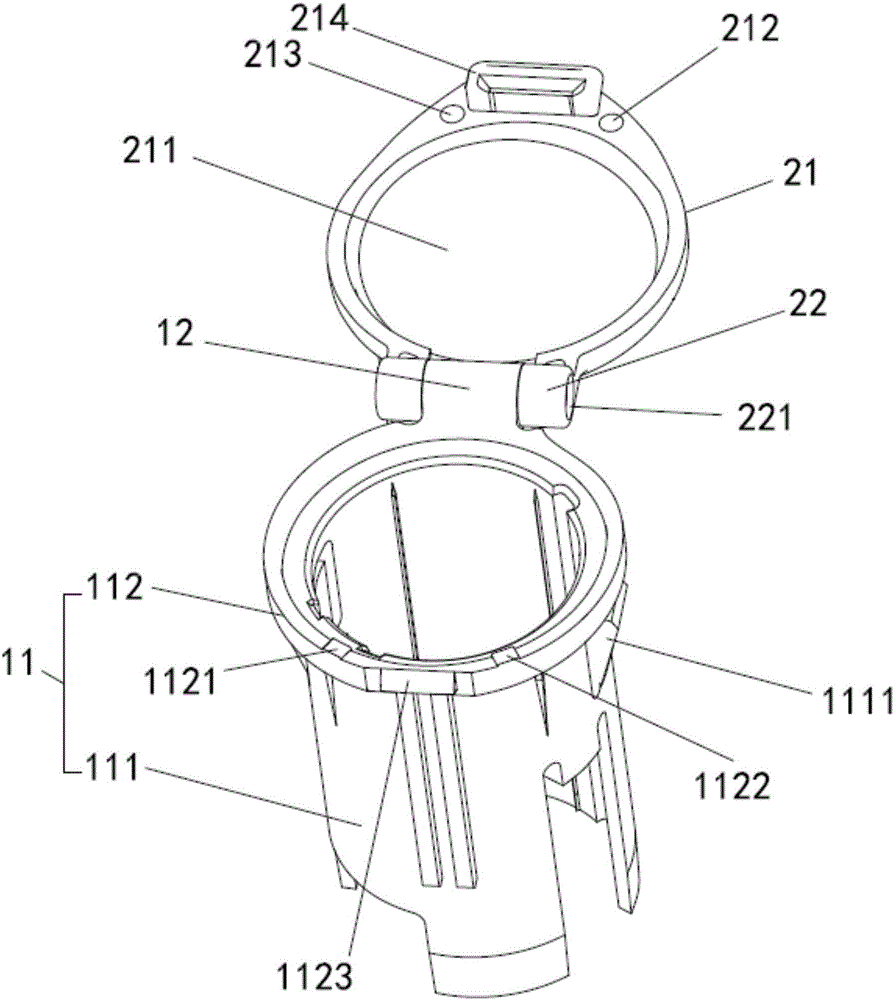

Power socket for vehicle

A technology for power sockets and vehicles, which is applied to circuits, electrical components, vehicle connectors, etc. It can solve problems such as short service life and uneven flip force control, and achieve shortened working hours, reliable and stable quality and performance, and good hand feeling. comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

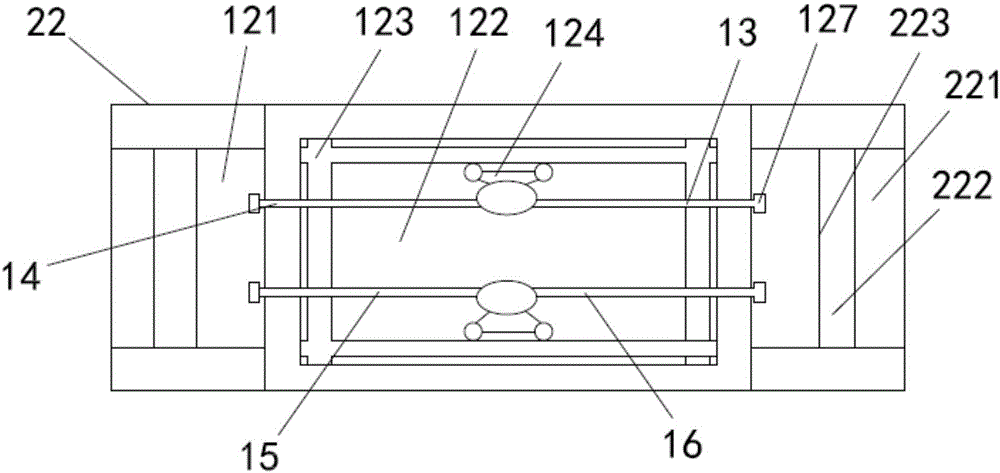

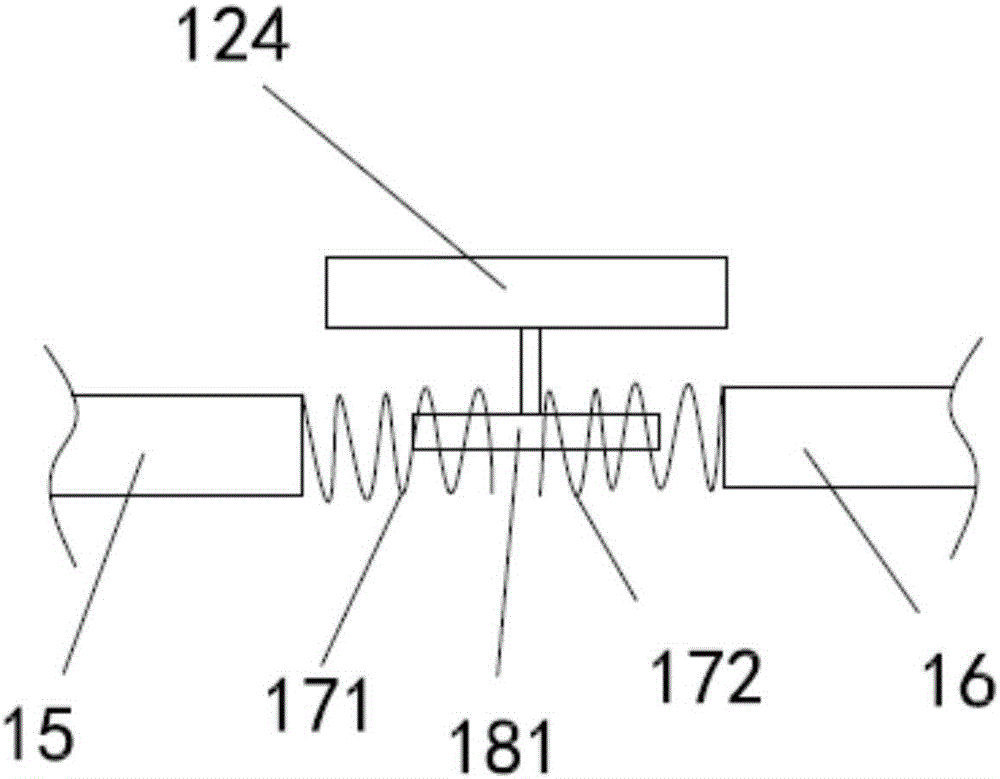

Method used

Image

Examples

Embodiment 1

[0055] (1) Making moulds: making clamshell molds and power base molds, and performing high-polish mirror treatment on the outer surface of the clamshell molds;

[0056] (2) The first injection molding: the clamshell mold is made of ABS material by one-time injection molding to form the clamshell;

[0057] The specific injection molding temperature parameters are as follows: baking material temperature: 100°C; time: 4 to 6 hours; mold temperature: fixed mold temperature 50°C±10°C, moving mold temperature 50°C±10°C; barrel temperature: first section: 220 ±10°C; second stage: 220±10°C; third stage: 215±10°C; fourth stage: 210±10°C; fifth stage: 200±10°C. Injection and pressure-holding parameters are as follows: Injection 1: pressure 70±10Mpa, injection 2: pressure 55±10Mpa, pressure-holding 1: 45±10Mpa.

[0058] (3) In-mold assembly: Put the prepared flip cover into the mold, and use the power base mold to assemble the flip cover and power base in the mold, so that the base shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com