A color inkjet 3D printing method with automatic flattening

A color inkjet, 3D printing technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problem of uneven product surface, improve printing efficiency, select a wide range of materials, and solve the effect of uneven product surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The technical solutions in the embodiments of the present invention are clearly and completely described below.

[0042] A self-levelling 3D inkjet printing material formulation blue jetting material comprising:

[0043] Colorant 2.9g:

[0044] Blue colorant (PENN COLOR 9S1494) 2.9g

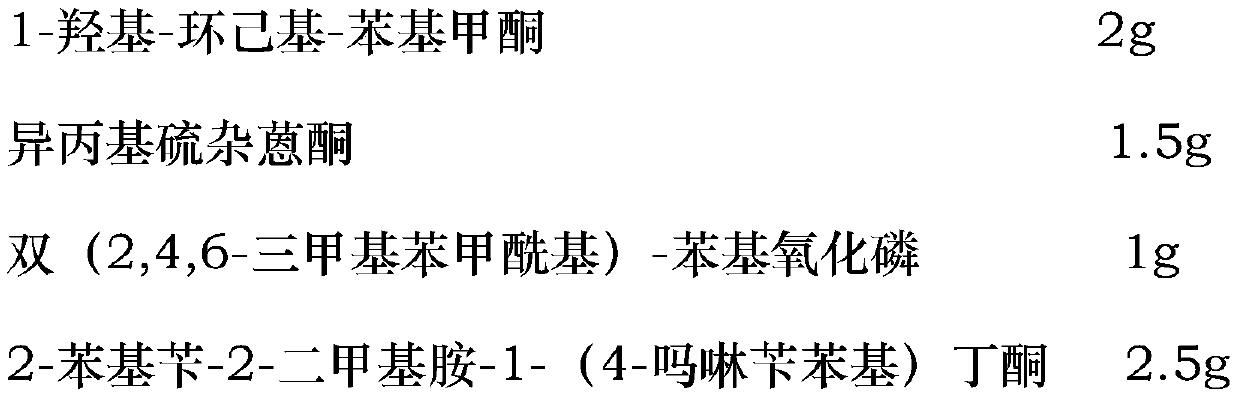

[0045] Photoinitiator 7g:

[0046]

[0047] UV-curable unsaturated monomer 84g:

[0048]

[0049] The above blue jet material has a viscosity of 10 cp at 25°C and a surface tension of 20 dynes. The red jetting material of the formula of a self-leveling 3D inkjet printing material includes: coloring agent 6.7g:

[0050] Red colorant (PENN COLOR 9R1519) 6.7g

[0051] Photoinitiator 1g:

[0052] 1-Hydroxy-cyclohexyl-phenylmethanone 1g

[0053] UV-curable unsaturated monomer 75g:

[0054] Neopentyl glycol diacrylate 48g

[0055] Trimethylolpropane Triacrylate 27g

[0056] Surfactant 0.2g:

[0057] BYK3500 0.2g

[0058] The above red spray material has a viscosity of 25 cp at 25...

Embodiment 2

[0076] A jetting material of a formulation of a self-leveling 3D inkjet printing material comprises:

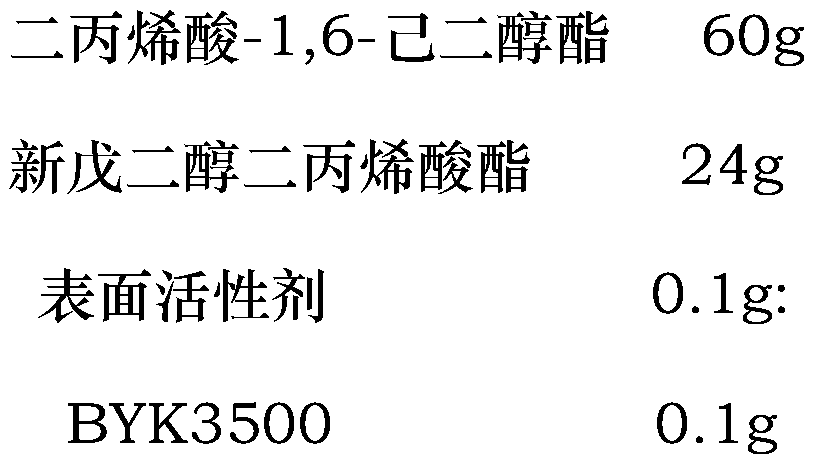

[0077] Photoinitiator 5.5g:

[0078] 1-Hydroxy-cyclohexyl-phenylmethanone 1g

[0079] Isopropylthioxanthone 2.5g

[0080] Bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide 2g

[0081] UV-curable unsaturated monomer 81.5g:

[0082] 2-Phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl)butanone 1.5g

[0083] Neopentyl glycol diacrylate 48g

[0084] Trimethylolpropane Triacrylate 32g

[0085] Surfactant 1g:

[0086] BYK3500 1g

[0087] The above sprayed material has a viscosity of 25 cp at 25°C and a surface tension of 50 dynes.

[0088] The preparation method of above injection material is:

[0089] In the dark, add the photoinitiator, UV-curable unsaturated monomer and surfactant into a stirring container according to the above weight, mix well under stirring, the stirring speed is 30 rpm, and then slowly Heating to 50°C for 30 minutes to fully dissolve the init...

Embodiment 3

[0104] A self-levelling 3D inkjet printing material formulation blue jetting material comprising:

[0105] Colorant 11.1g:

[0106] Black colorant (PENN COLOR 9B989) 11.1g

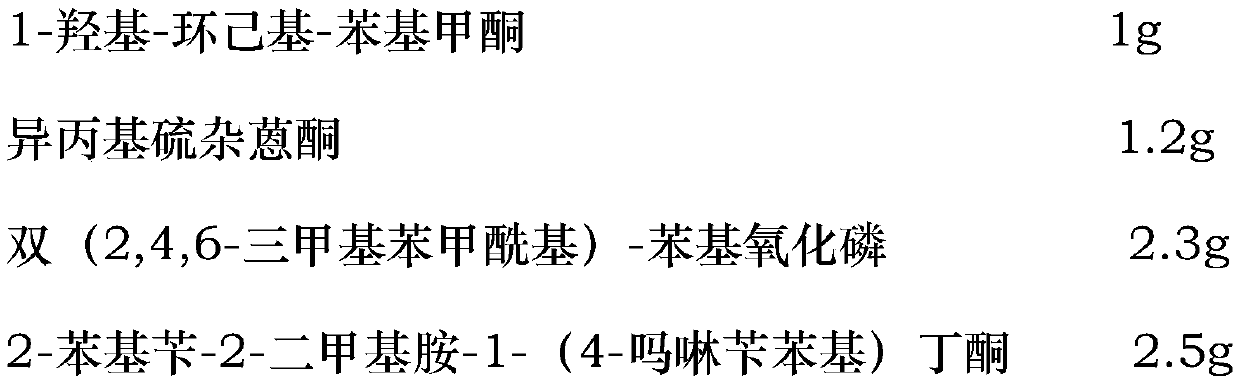

[0107] Photoinitiator 7g:

[0108]

[0109] UV-curable unsaturated monomer 88g:

[0110] Pentaerythritol Triacrylate 28g

[0111] Neopentyl glycol diacrylate 60g

[0112] Surfactant 1g:

[0113] BYK3500 0.1g

[0114] The above sprayed material has a viscosity of 50 cp at 25°C and a surface tension of 50 dynes.

[0115] The preparation method of above injection material is:

[0116] Preparation of black spray material: In the dark, add the photoinitiator, UV-curable unsaturated monomer and surfactant into a stirring container according to the above weight, and mix evenly under stirring at a stirring speed of 30 rpm, and then slowly heated to 60°C for 10 minutes to allow the initiator to fully dissolve and form a homogeneous mixture, then lower the temperature to about 30°C, and at a stirring spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com