A kind of preparation method of perfluoro-2-methyl-2-pentene

A methyl, pentene technology, applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problem of low perfluoro-2-methyl-2-pentene content, strong catalyst water absorption, and catalyst Toxic problems, to achieve the effect of low cost, simple separation, high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

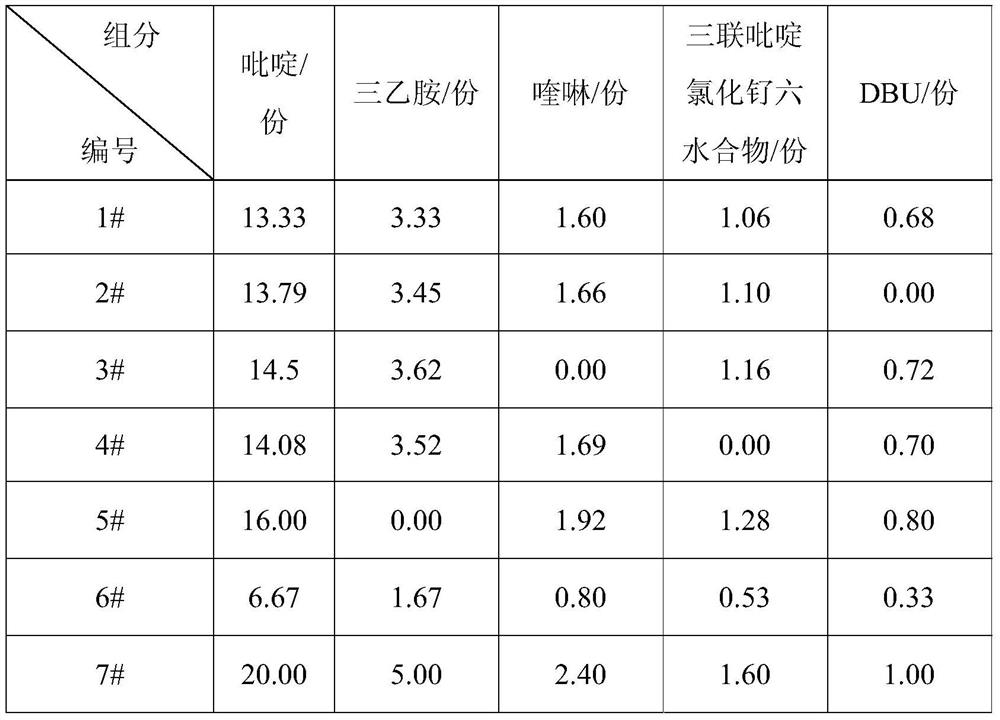

[0032] Add 1# catalyst (see Table 1 for composition) 12.0g, 20.0g of potassium carbonate and 66.7g of acetonitrile in 1L autoclave that internal cooling coil pipe is housed, N 2 Vacuumize the reaction kettle after 3 times, and pass 1000g of hexafluoropropylene gas at a constant speed at 50±2°C. After the gas is passed, the temperature is raised to 70°C. After 8 hours of reaction, the reaction is stopped, and the materials in the reaction kettle are released from the bottom of the reaction kettle. The product and the catalyst solvent system were immiscible, and 960 g of the lower layer reaction product was obtained by liquid separation operation, and the content of perfluoro-2-methyl-2-pentene in the product was analyzed by gas chromatography to be 99.6%.

Embodiment 2

[0034]Add 2# catalyst (see Table 1 for composition) 25.0g in 1L autoclave that internal cooling coil is housed, potassium carbonate 30.0g and acetonitrile 1000.0g, N 2 After replacing the reactor for 3 times, vacuumize, and pass 1000g of hexafluoropropylene gas at a constant speed at 50±2°C. After the gas is passed, the temperature is raised to 110°C. After 5 hours of reaction, the reaction is stopped, and the materials in the reactor are released from the bottom of the reactor. The product and the catalyst solvent system were immiscible, and 941 g of the lower layer reaction product was obtained by liquid separation operation, and the content of perfluoro-2-methyl-2-pentene in the product was analyzed by gas chromatography to be 99.4%.

Embodiment 3

[0036] Add 3# catalyst (see Table 1 for composition) 12.5g in 1L autoclave that internal cooling coil is housed, potassium carbonate 30.0g and acetonitrile 100.0g, N 2 Vacuumize the reaction kettle after 3 times, pass 1000g of hexafluoropropylene gas at a constant speed at 50±2°C, heat up to 80°C after the gas is passed through, stop the reaction after 7 hours of reaction, and release the materials in the reaction kettle from the bottom of the reaction kettle. The product and the catalyst solvent system were immiscible, and 908 g of the lower layer reaction product was obtained by liquid separation operation, and the content of perfluoro-2-methyl-2-pentene in the product was analyzed by gas chromatography to be 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com