Automatic leveling color inkjet 3D printing method

A color inkjet, 3D printing technology, used in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problem of product surface inequality, improve printing efficiency, solve product surface unevenness, and select a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The technical solutions in the embodiments of the present invention are clearly and completely described below.

[0042] The blue jetting material of the formula of an automatically smoothed 3D inkjet printing material includes:

[0043] Coloring agent 2.9g:

[0044] Blue colorant (PENN COLOR 9S1494) 2.9g

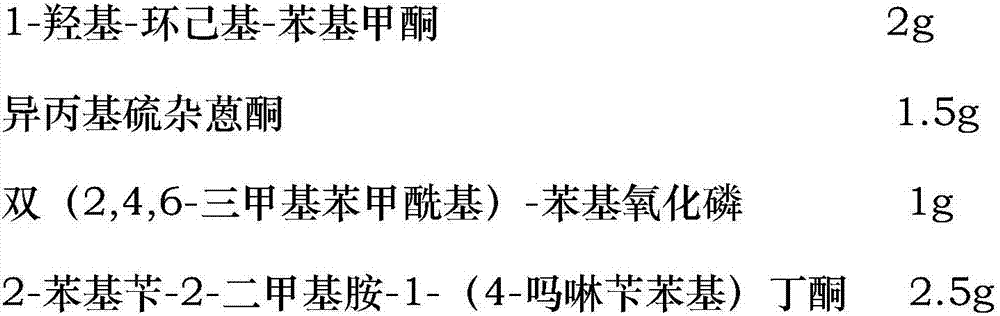

[0045] Photoinitiator 7g:

[0046]

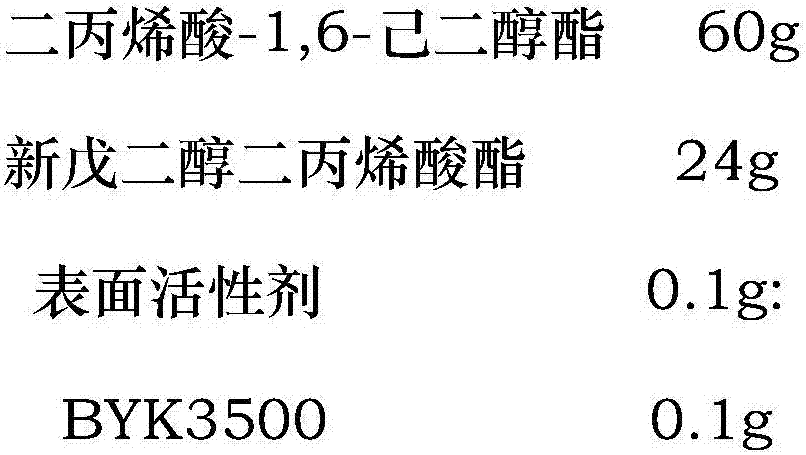

[0047] 84g of UV-curable unsaturated monomer:

[0048]

[0049] The above blue spray material has a viscosity of 10 cp at 25°C and a surface tension of 20 dynes. The red jetting material of the formula of an automatically smoothed 3D inkjet printing material includes: colorant 6.7g:

[0050] Red colorant (PENN COLOR 9R1519) 6.7g

[0051] Photoinitiator 1g:

[0052] 1-hydroxy-cyclohexyl-phenyl ketone 1g

[0053] 75g of UV-curable unsaturated monomer:

[0054] Neopentyl glycol diacrylate 48g

[0055] Trimethylolpropane triacrylate 27g

[0056] Surfactant 0.2g:

[0057] BYK3500 0.2g

[0058] The above red spray material has a viscosity of 25 cp at 25°C...

Embodiment 2

[0076] A kind of spray material for the formulation of an automatically smoothed 3D inkjet printing material includes:

[0077] Photoinitiator 5.5g:

[0078] 1-hydroxy-cyclohexyl-phenyl ketone 1g

[0079] Isopropyl thioxanthone 2.5g

[0080] Bis(2,4,6-trimethylbenzoyl)-phenylphosphorus oxide 2g

[0081] 81.5g of UV-curable unsaturated monomer:

[0082] 2-phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl)butanone 1.5g

[0083] Neopentyl glycol diacrylate 48g

[0084] Trimethylolpropane triacrylate 32g

[0085] Surfactant 1g:

[0086] BYK3500 1g

[0087] The above spray material has a viscosity of 25cp at 25°C and a surface tension of 50 dynes.

[0088] The preparation method of the above spray material is:

[0089] In the dark, add the photoinitiator, the UV-curable unsaturated monomer and the surfactant according to the above weight into a container with stirring, and mix well under stirring. The stirring speed is 30 rpm, and then slowly Heat to 50°C for 30 minutes to allow the initiato...

Embodiment 3

[0104] The blue jetting material of the formula of an automatically smoothed 3D inkjet printing material includes:

[0105] Coloring agent 11.1g:

[0106] Black colorant (PENN COLOR 9B989) 11.1g

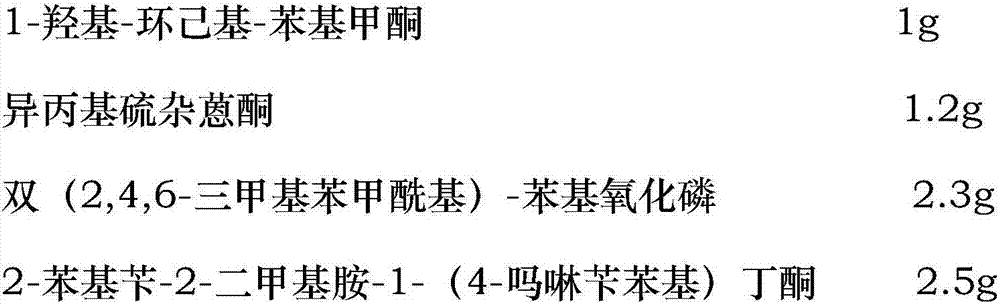

[0107] Photoinitiator 7g:

[0108]

[0109] 88g of UV-curable unsaturated monomer:

[0110] Pentaerythritol triacrylate 28g

[0111] Neopentyl glycol diacrylate 60g

[0112] Surfactant 1g:

[0113] BYK3500 0.1g

[0114] The above spray material has a viscosity of 50 cp at 25°C and a surface tension of 50 dynes.

[0115] The preparation method of the above spray material is:

[0116] Preparation of black spray material: In the dark, add the photoinitiator, UV-curable unsaturated monomer and surfactant to a container with stirring according to the above weight, and mix evenly under stirring at a stirring speed of 30 Rpm, then slowly heat to 60℃, heating time is 10 minutes, let the initiator fully dissolve and form a homogeneous mixture, then reduce the temperature to about 30℃, under the stirring spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com