Chemical corrosive liquid and applications thereof

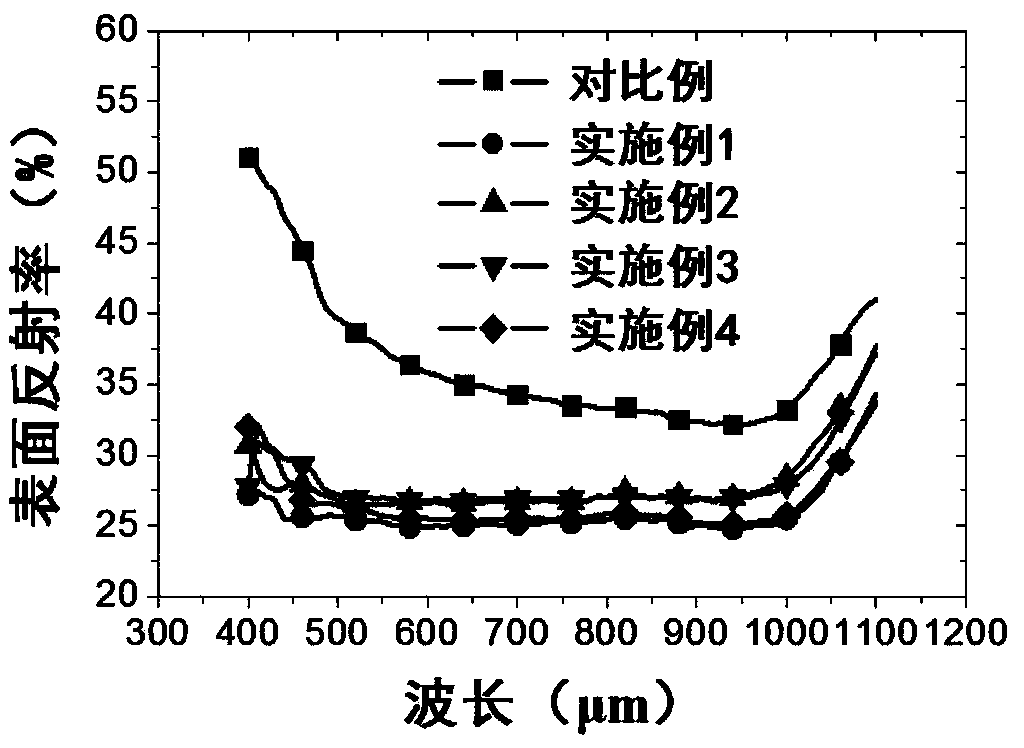

A technology of chemical corrosion and corrosion solution, which is applied in chemical instruments and methods, surface etching compositions, crystal growth, etc., can solve the problems of high process cost, low parallel resistance of solar cells, and too small feature size of textured surface, etc., to achieve Effects of reducing light reflectance, improving anti-reflection performance, and increasing aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention does not have special requirement to the preparation method of described chemical etchant, directly MnO 2 Particles, HNO 3 , HF and H 2 O can be mixed evenly according to the concentration requirements.

[0027] The present invention also provides the application of the chemical etching solution described in the above technical solution in silicon wafer etching.

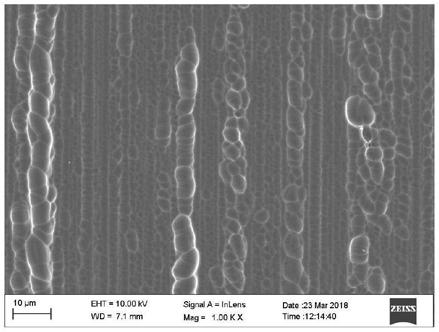

[0028] In the present invention, the application is preferably textured on the surface of silicon wafers; the silicon wafers are preferably polycrystalline silicon wafers; more preferably polycrystalline silicon wafers obtained by diamond wire cutting. In the present invention, the step of texturizing the silicon wafer preferably includes: corroding the silicon wafer in the chemical etching solution described in the above technical solution. In the present invention, the corrosion time is preferably less than 60 minutes. Corrosion process of the present invention, anti-genetic followi...

Embodiment 1

[0041] A MnO-containing 2 particulate HNO 3 / HF / H 2 O chemical etching solution, wherein, the MnO 2 Particles are powder particles below 10 μm, and their dosage in the chemical corrosion solution is 30g / L; the HNO 3 The concentration in the chemical etching solution is 8.5mol / L; the concentration of the HF in the chemical etching solution is 2.5mol / L.

[0042] The method for making texture on the surface of a polycrystalline silicon chip using the chemical etching solution comprises the following steps in order:

[0043] (1) Put the diamond wire-cut polysilicon wafer into the MnO-containing 2 particulate HNO 3 / HF / H 2 Take out after 180s corrosion in O chemical etching solution at room temperature;

[0044] (2) With 5.0wt.% NaOH / H 2 O alkali solution is taken out after corrosion treatment at room temperature for 15s to remove porous silicon;

[0045] (3) HF / HCl / H with HF concentration of 2.8mol / L and HCl concentration of 3.2mol / L 2 O solution was washed for 2 minutes...

Embodiment 2

[0048] A MnO-containing 2 particulate HNO 3 / HF / H 2 O chemical etching solution, wherein, the MnO 2 Particles are powder particles below 10 μm, and their content in the chemical corrosion solution is 30g / L; the HNO 3 The concentration in the chemical etching solution is 9.4mol / L; the concentration of the HF in the chemical etching solution is 1.1mol / L.

[0049] The method for making texture on the surface of a polycrystalline silicon chip using the chemical etching solution comprises the following steps in order:

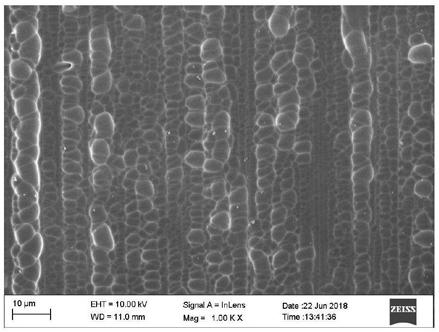

[0050] (1) Put the diamond wire-cut polysilicon wafer into the MnO-containing 2 particulate HNO 3 / HF / H 2 Take out after 90s corrosion in O chemical etching solution at room temperature;

[0051] (2) With 2.0wt.% NaOH / H 2 O alkali solution is taken out after 40s corrosion treatment at room temperature to remove the porous silicon;

[0052] (3) HF / HCl / H with HF concentration of 2.0mol / L and HCl concentration of 3.5mol / L 2 O solution was washed for 5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com