Forging double-layer multi-color wool warp towel and manufacturing process thereof

A kind of wool warp and towel technology, which is applied to multi-strand fabrics, textiles, papermaking, textiles, etc., can solve the problems of sparse loops, unequal proportions of double-layer towels, and products are prone to cracking, etc., to achieve soft hand feel and organizational structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A double-layer multi-color wool warp towel with lifting and forging

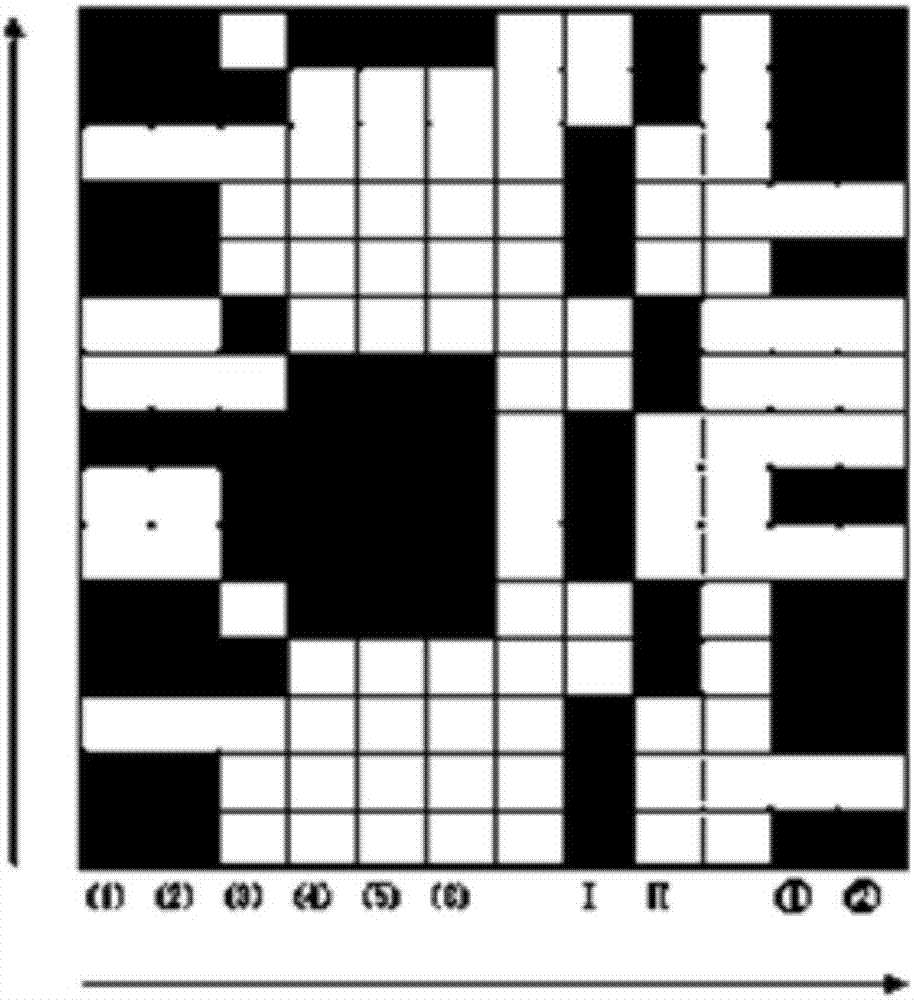

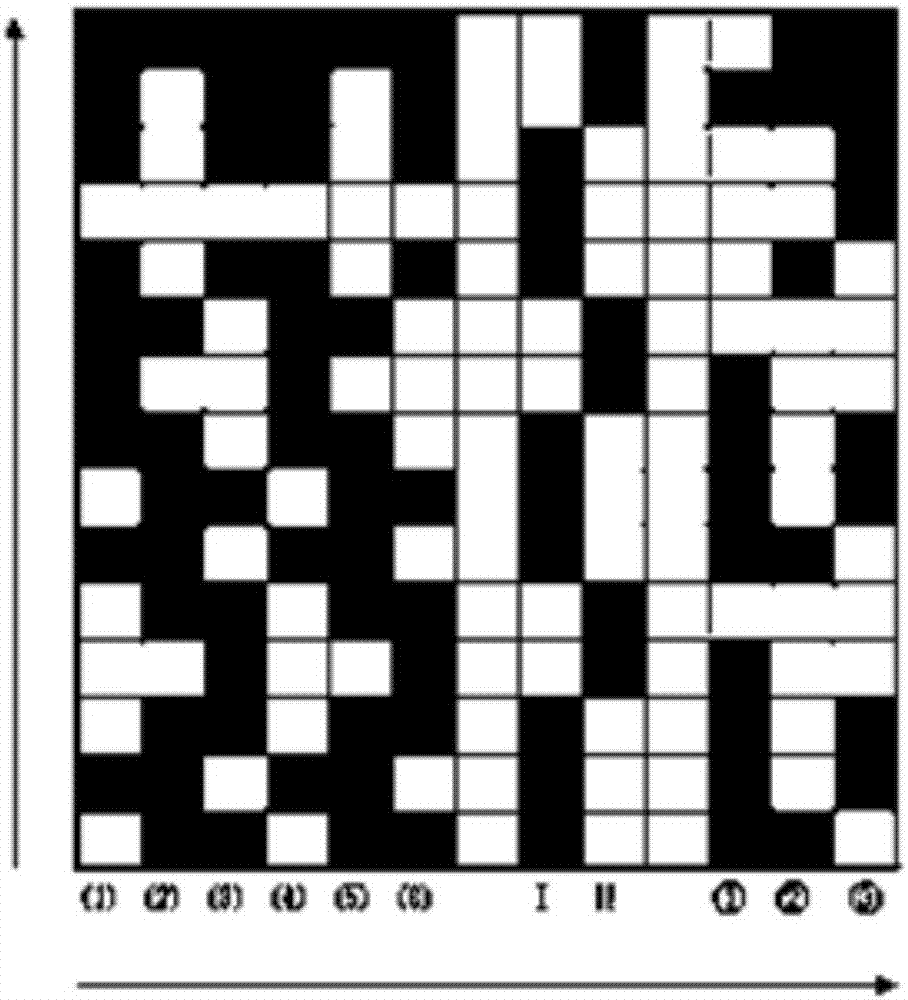

[0038] figure 2 It shows the tissue diagram of a double-layer, two-color turned-over towel provided by the present invention with a five-weft raising method. A double-layer multi-color wool warp towel, which is woven from ground warp, wool warp and weft yarn, includes flower-shaped terry weave, plain cloth weave and reverse terry weave, the flower-shaped terry weave and flat cloth weave Distributed on the front side of the towel, the plain fabric is distributed around the flower-shaped terry weave; the flower-shaped terry weave and the reverse terry weave are made of two yarns with different characteristics and different colors as the pile warp, which is different from the ground warp , Weft yarn interweaving. The two yarns with different characteristics form flower-shaped piles and reverse piles on the surface of the towel through the transformation of the structure and the exchange of positions. ...

Embodiment 2

[0045] A manufacturing process of forging double-layer multi-color wool warp towel

[0046] For ease of description, this embodiment focuses on the improved part of the manufacturing process. Include the following steps:

[0047] 1) spinning

[0048] Choose untwisted yarns of different colors and siro spun yarns as the wool warp, and the ground warp and weft yarns are cotton yarns. The untwisted yarn is formed by the reverse twisting method of cotton yarn and water-soluble yarn, and the cotton yarn and water-soluble yarn are combined by the reverse twisting method when twisting, and the twist of the cotton yarn is twisted when the yarn is combined. Solve it. After the water treatment, the water-soluble silk is dissolved, and the remaining cotton yarn has a small twist. Siro spinning is synchronous twisting in the same direction, and the fibers in the sliver are basically in a spiral shape around the axis of the ply yarn.

[0049] 2) Warping

[0050] The yarn of step 1) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com