Nanowire semiconductor device and formation method thereof

一种半导体、纳米线的技术,应用在纳米线半导体器件及其形成领域,能够解决难以保证器件性能及其稳定性等问题,达到表面圆滑、分布均匀、改善性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It can be seen from the background art that the nanowire semiconductor devices formed in the prior art have the problem of poor performance. The reasons for the poor performance are analyzed in combination with the formation process of nanowire semiconductor devices:

[0042] refer to Figure 1 to Figure 4 , is a schematic structural view showing various steps of a method for forming a nanowire semiconductor device in the prior art.

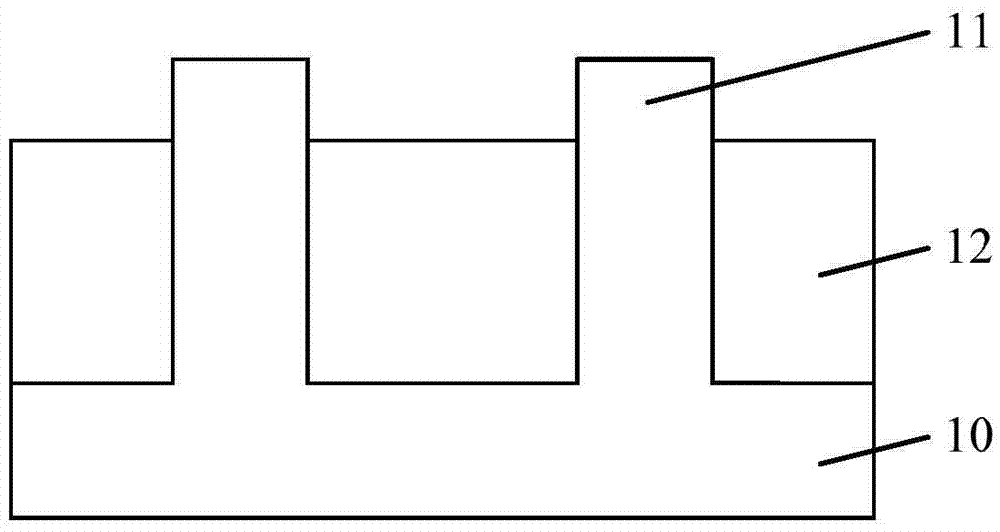

[0043] refer to figure 1 , providing a silicon substrate 10 . The substrate 10 is etched to form fins 11 , and an isolation layer 12 is formed between adjacent fins 11 .

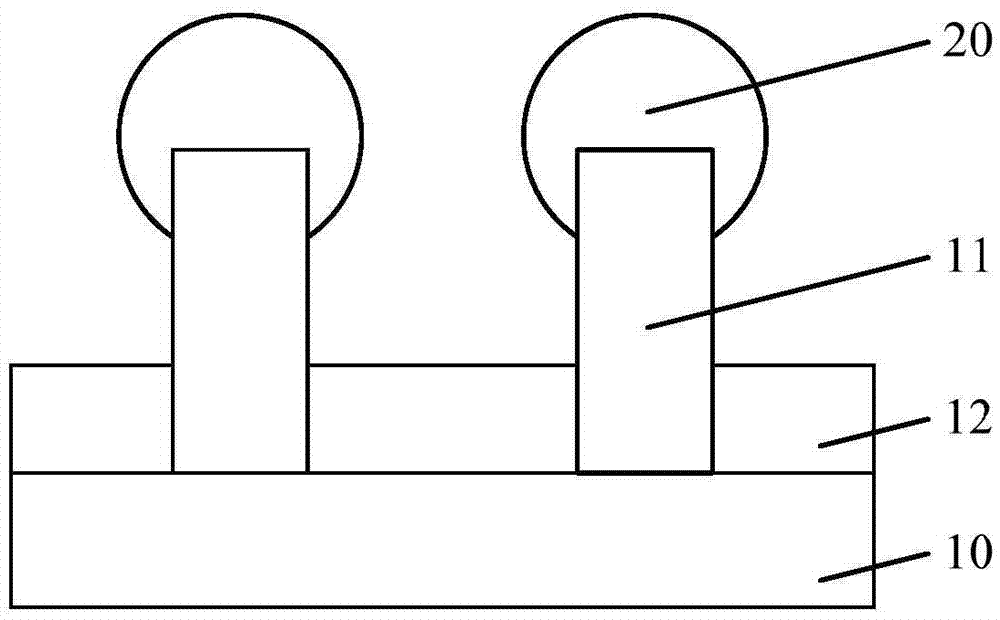

[0044] refer to figure 2 A SiGe epitaxial line 20 is formed on the top of the fin portion 11 by selective epitaxy. Afterwards, the isolation structure 12 is etched back to expose part of the side surfaces of the fins 11 .

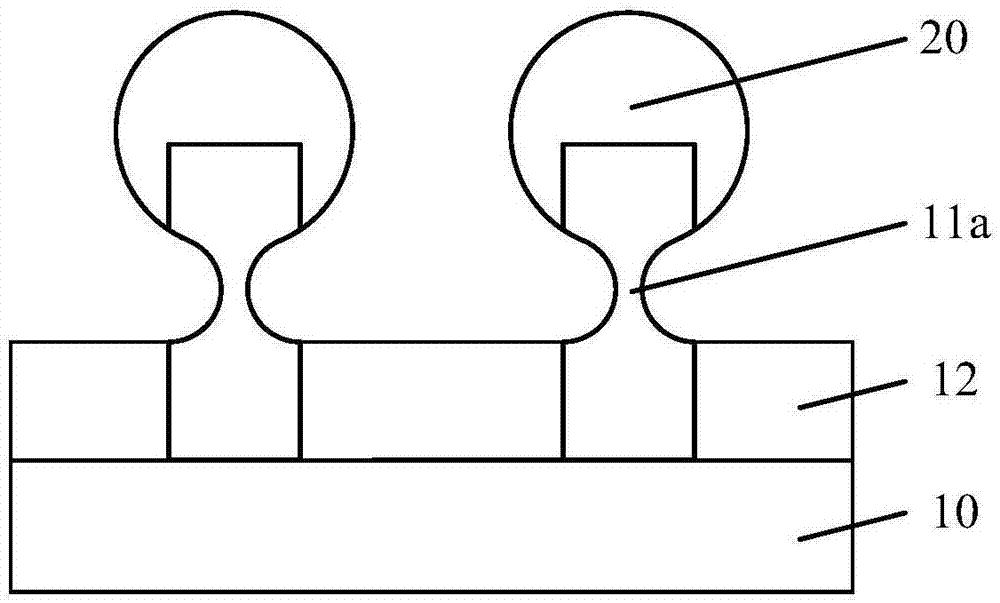

[0045] refer to image 3 , removing part of the thickness of the side of the fin 11 , so that the side of the fin 11 is necked-in.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com