Desulfuration demisting integrated absorption tower

The technology of absorption tower and mist pipe is applied in the field of removing pollutants from coal-fired flue gas, which can solve the problems of difficulty in reconstruction, affecting the water supply system of desulfurization equipment, complex structure of compound mist eliminator, etc.

Inactive Publication Date: 2017-06-20

DATANG ENVIRONMENT IND GRP

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it can guarantee the service life of the ridge type demister to a certain extent, its demisting effect is not significantly improved, and it mainly removes fog droplets larger than 400-500μm. The most important thing is that the patented composite demister The structure of the demister is very complicated, and it is necessary to combine the tube type mist eliminator and the roof type mist eliminator into a whole, which is obviously not suitable for the renovation project. If the existing equipment needs to be transformed, the cost is high, the construction period is long, and the transformation is

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

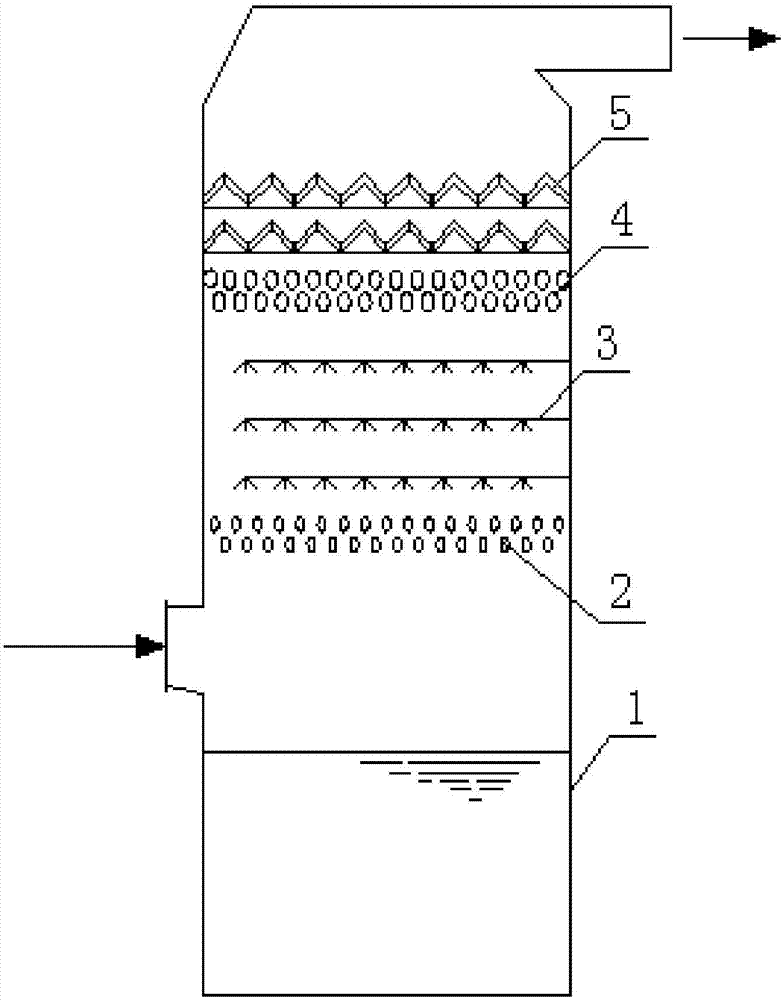

The invention provides a desulfuration demisting integrated absorption tower. The desulfuration demisting integrated absorption tower comprises a tower body taken as flue gas channel; the tower body is provided with a flue gas inlet and a flue gas outlet; in the tower body, a synergistic component layer, a plurality of spraying layers, a tube-type demister layer, and a ridge-type demister layer are arranged along the flow direction of flue gas successively; the synergistic component layer is used for forming turbulence states of flue gas; the tube-type demister layer is used for removing liquid drops in flue gas via tubes arranged at intervals. The desulfuration demisting integrated absorption tower is capable of improving removing effect of desulfuration absorption towers on fog drops carried by SO2 and flue gas, reducing SO2 emission concentration of coal-fired flue gas to 35mg/Nm3, and reducing fog drop carrying amount in coal-fired flue gas to be lower than 10mg/Nm3.

Description

technical field [0001] The invention relates to the technical field of coal-burning flue gas pollutant removal, in particular to a desulfurization and demisting absorption tower, in particular to an integrated desulfurization and demisting absorption tower. Background technique [0002] Due to my country's energy structure that is poor in oil, less in gas and rich in coal, the energy consumption structure dominated by coal will continue for a long time in my country, and the consumption of coal is mainly concentrated in industries such as electric power, steel, and cement. Coal combustion is the main reason for the frequent occurrence of smog and the increasingly serious situation of air pollution emissions in my country. [0003] For this reason, under the pressure of increasingly stringent environmental protection emission requirements, on September 12, 2014, the three ministries and commissions jointly issued the "Coal Power Energy Conservation and , Tianjin, Hebei, Shan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/80B01D53/50B01D45/08

CPCB01D53/80B01D45/08B01D53/50

Inventor 杜明生谷小兵张若雨赵怡凡马务李穹

Owner DATANG ENVIRONMENT IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com