High-efficiency calibrating and leveling machine for silicon steel columns

A leveling machine and silicon steel technology, applied in the field of silicon steel column processing, can solve the problems of poor correction effect and complicated operation, and achieve the effect of reducing adjustment and trimming, increasing the correction area, and reducing the overall correction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

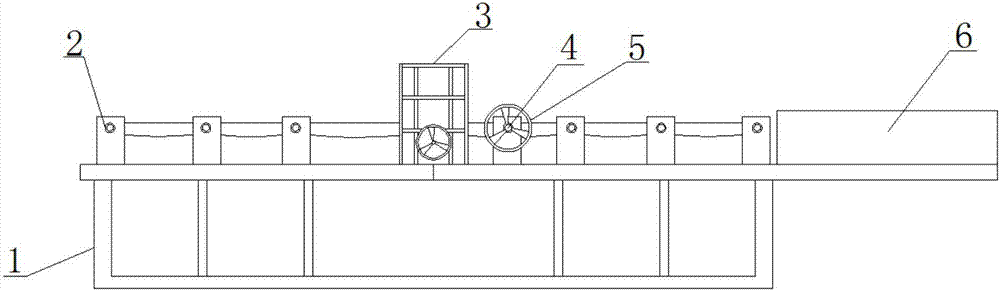

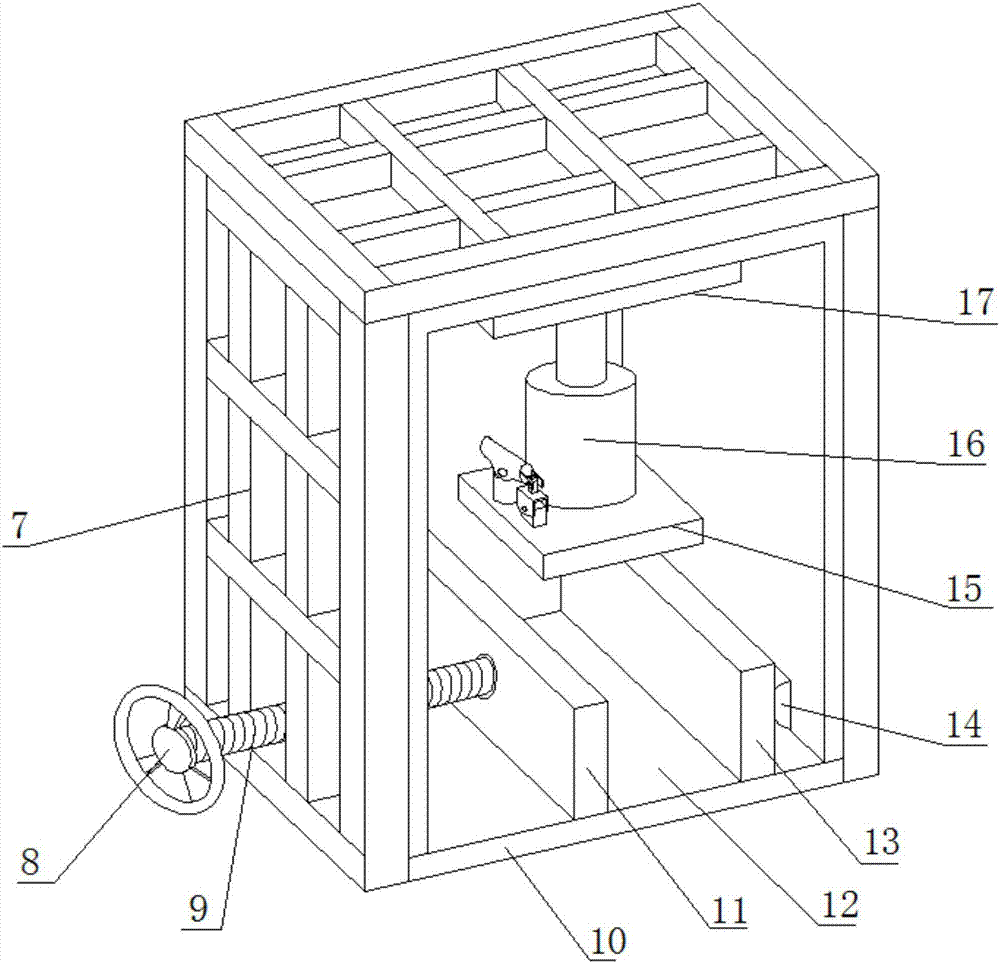

[0034] Such as Figure 1-Figure 7 As shown, the high-efficiency correction and leveling machine for silicon steel columns includes a frame 1, a correction and leveling device 3 located in the middle of the upper end of the frame 1, and a plurality of transmission shafts 2 arranged in a straight line and equidistant on both sides of the correction and leveling device 3. All transmission shafts 2 are driven to rotate in the same direction through the transmission system;

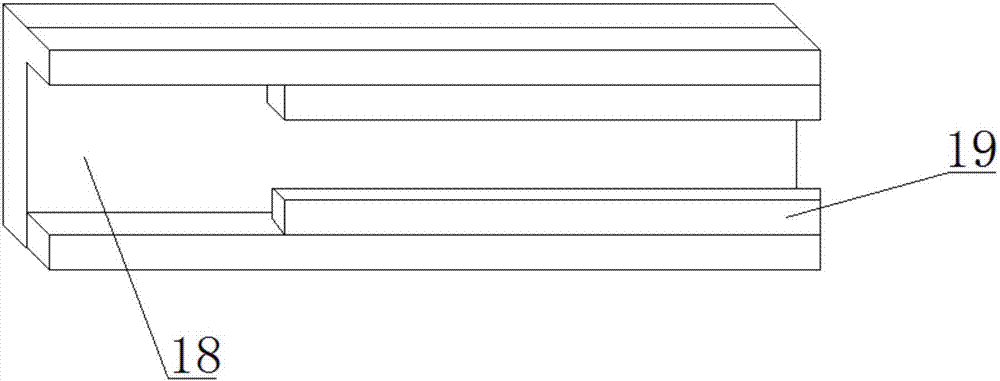

[0035] The correction and leveling device 3 includes a square frame body 10 made of four metal plates, the inside of the square frame body 10 is located above the metal plate at the lower end, and a first splint 13 and a second splint 11 are oppositely arranged, and the second splint 11 can be opposite to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com