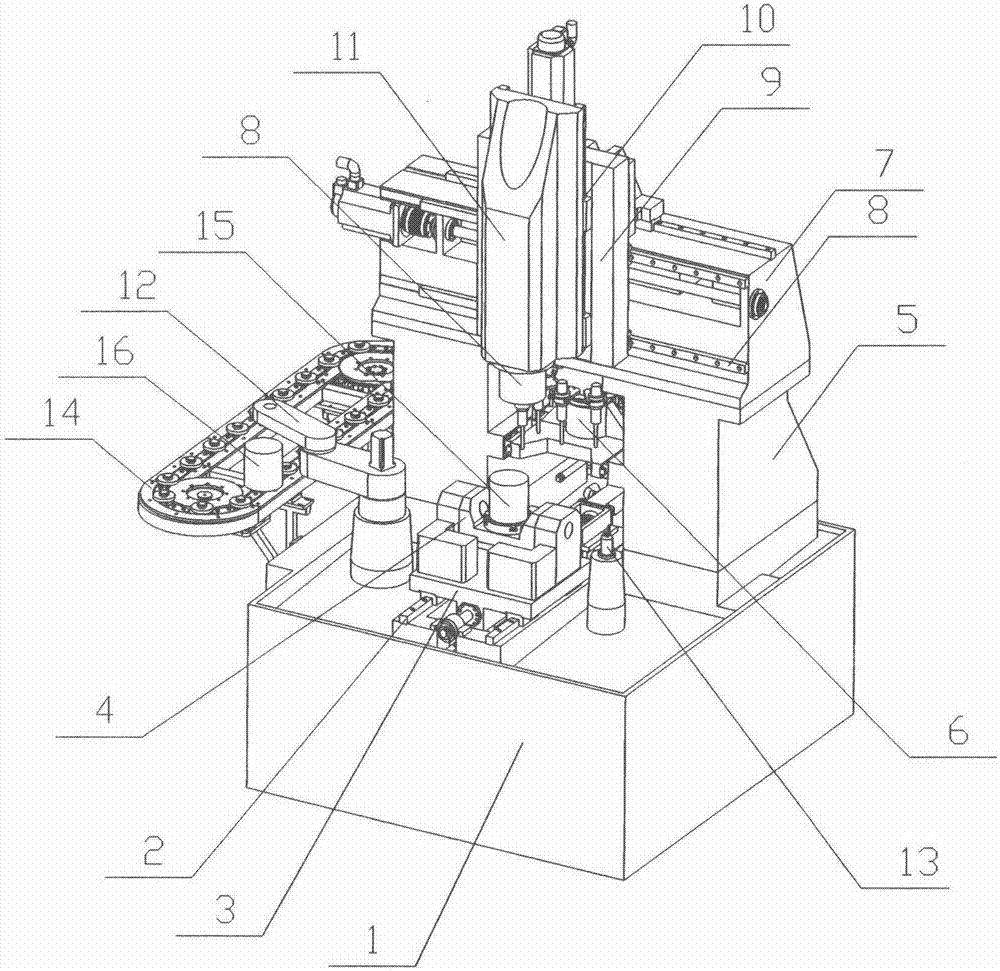

Miniaturized gantry type five-axis processing equipment

A processing equipment, gantry-type technology, applied in metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of time-consuming installation and adjustment, difficulty in achieving workpiece processing accuracy, and insufficient overall structural strength, etc. Productivity, simple installation, and the effect of shortening auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

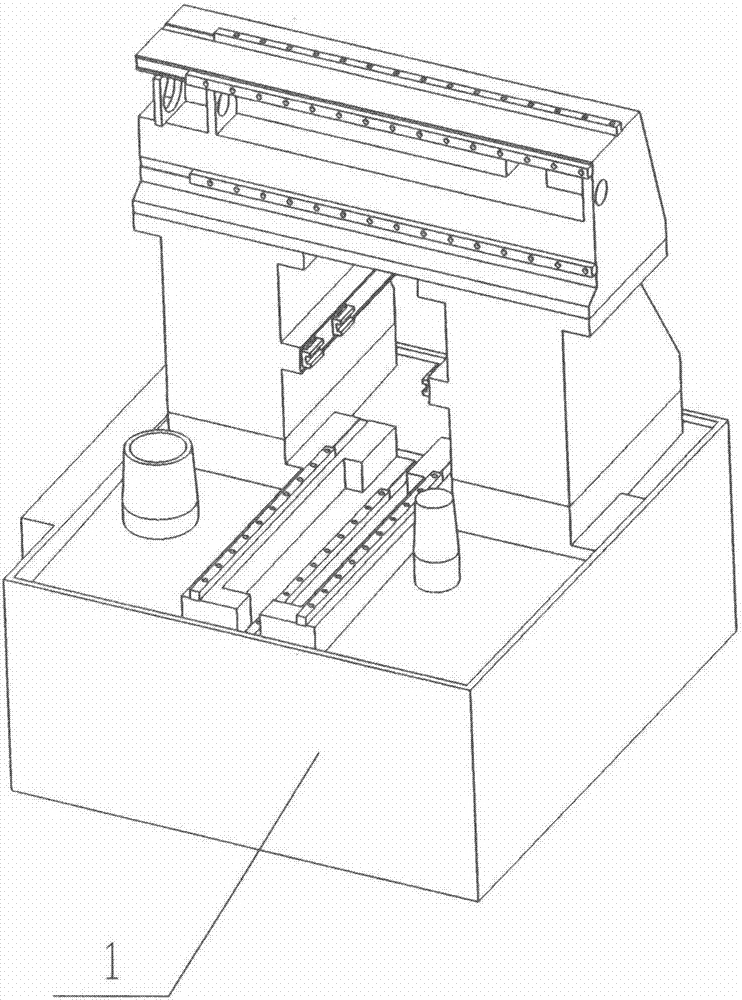

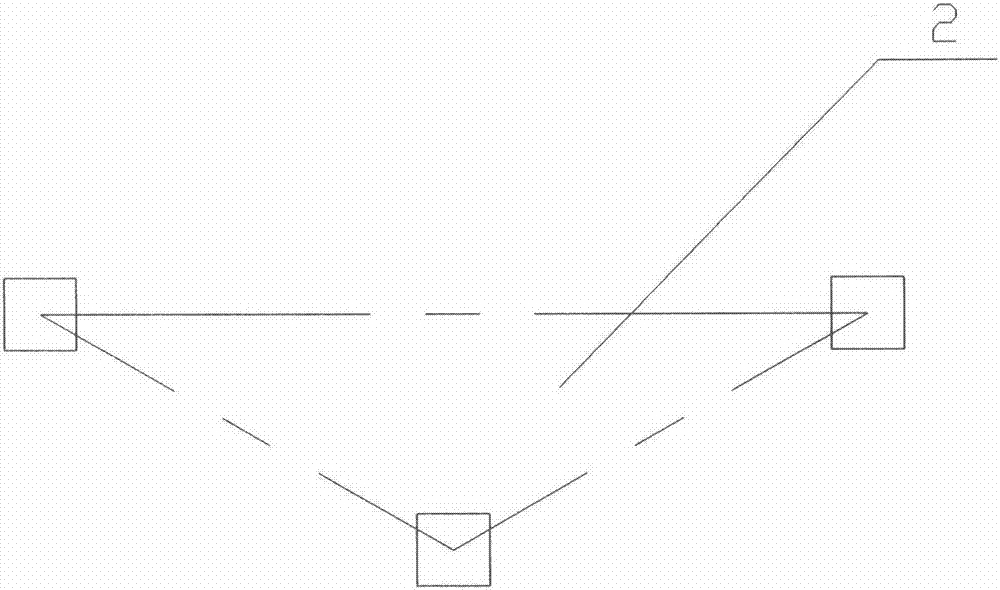

[0029] like Figure 1-Figure 8 As shown, this specific embodiment adopts the following technical scheme: it includes bed base 1, X-axis guide rail 2, X-axis carriage 3, double rotary table 4, column 5, mobile tool magazine 6, beam 7, Y-axis Guide rail 8, Y-axis carriage 9, Z-axis guide rail 10, spindle ram 11, mechanical arm 12, tool setting instrument 13, ring discharge device 14, X-axis guide rail 2 is fixed on the front of bed base 1, and X-axis The guide rail 2 is three parallel linear guide rails in a triangular layout in space. The X-axis carriage 3 is installed on the X-axis guide rail 2 and moves along the X direction. The X-axis carriage 3 is equipped with a double rotary table 4. The front part of the base 1 is also equipped with a first motor seat and a first tail end seat, an X-axis screw rod is arranged between the first motor seat and the first tail end seat, and the nut method of the X-axis screw rod and the X-axis carriage 3 Combining the blue and the surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com