Table vibration building block forming machine capable of manufacturing height being 500 mm

A block forming machine and forming mechanism technology, applied in the direction of ceramic forming machines, forming pressure heads, auxiliary forming equipment, etc., can solve the problem that the overall height of the lifting drive device cannot be made very high, and the lifting stroke cannot be too short or too long , unable to simultaneously lift and lower both sides of the pressure head, etc., to achieve the effect of wide setting range, good molding quality, and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

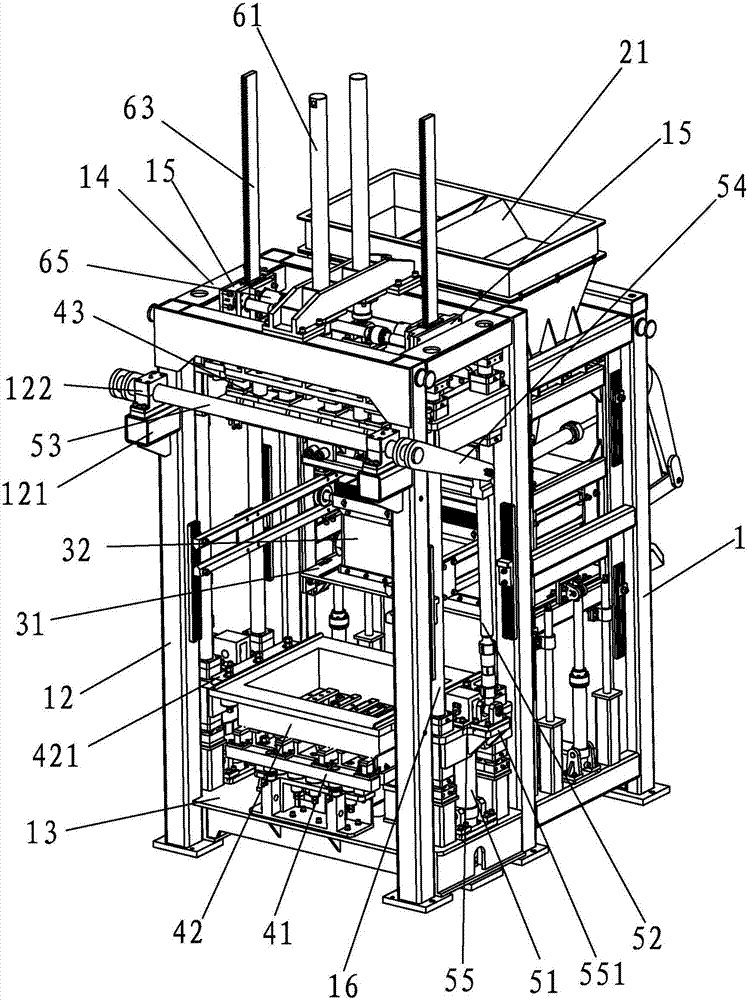

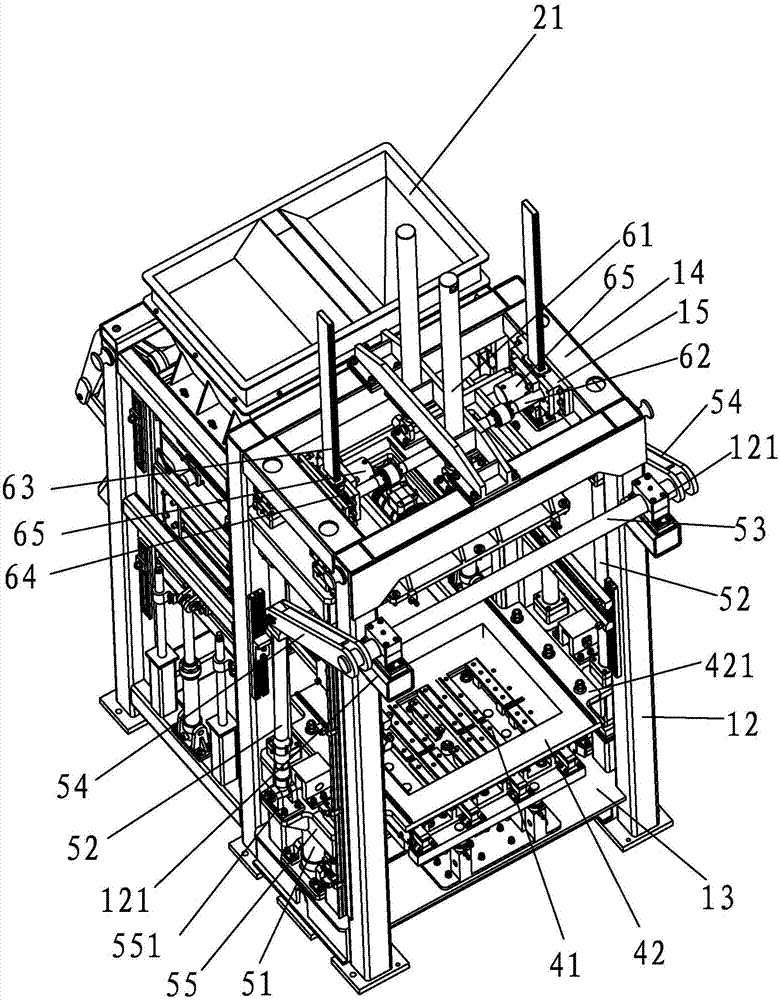

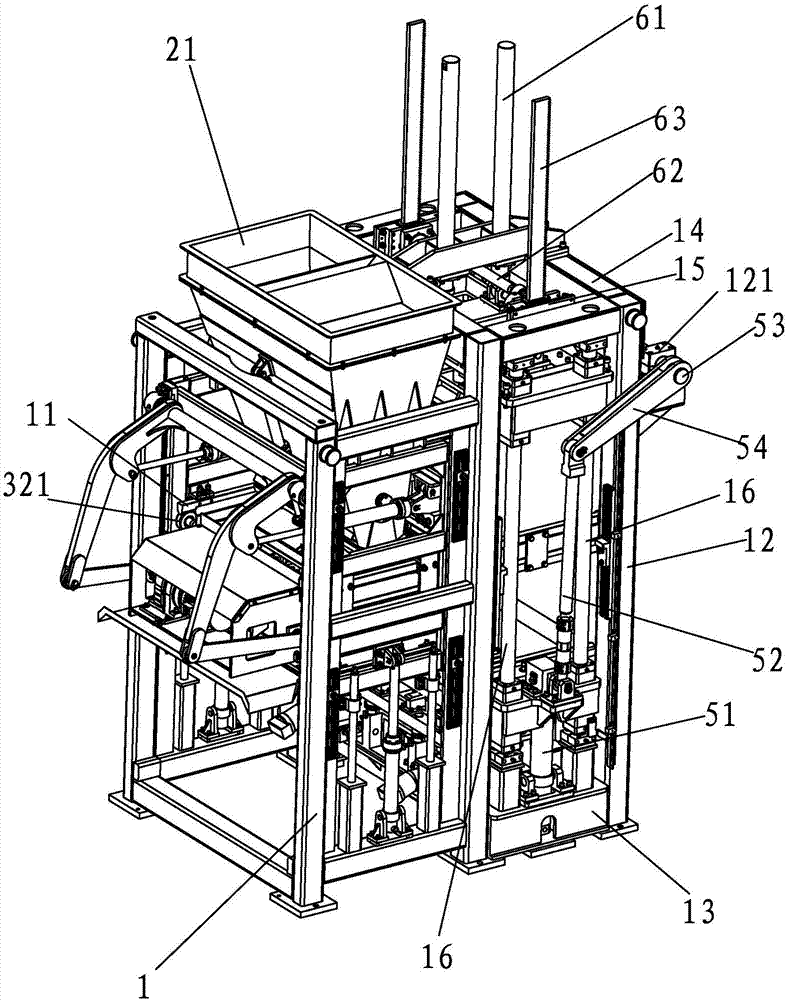

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] A kind of 500mm high table vibration block forming machine of the present invention, such as Figure 1-4 As shown, it includes the frame 1 and the unloading mechanism, the material distribution mechanism and the forming mechanism in the frame 1. The unloading mechanism includes a hopper 2 and a control structure that controls the opening or closing of the outlet of the hopper 2 below the hopper 2. (not marked in the figure), the hopper 2 is above the rear portion of the frame, and what this feeding mechanism adopts is a known technology, which will not be repeated here. The feeding mechanism is directly below the feeding mechanism, and the feeding mechanism includes The bottom plate 31 is laid flat on the cloth trolley 32 on the bottom plate 31. The bottom plate 31 is fixed on the frame 1, and the cloth trolley 32 is movable and installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com