Wallboard frame, wallboard frame die and combination of wallboard frame and wallboard frame die

A frame and wall panel technology, applied in the field of wall panel frames, frame molds and their combinations, can solve the problems of environmental emissions, environmental emissions, slow drying, etc., and achieve the effects of not easy to crack, simple connection, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

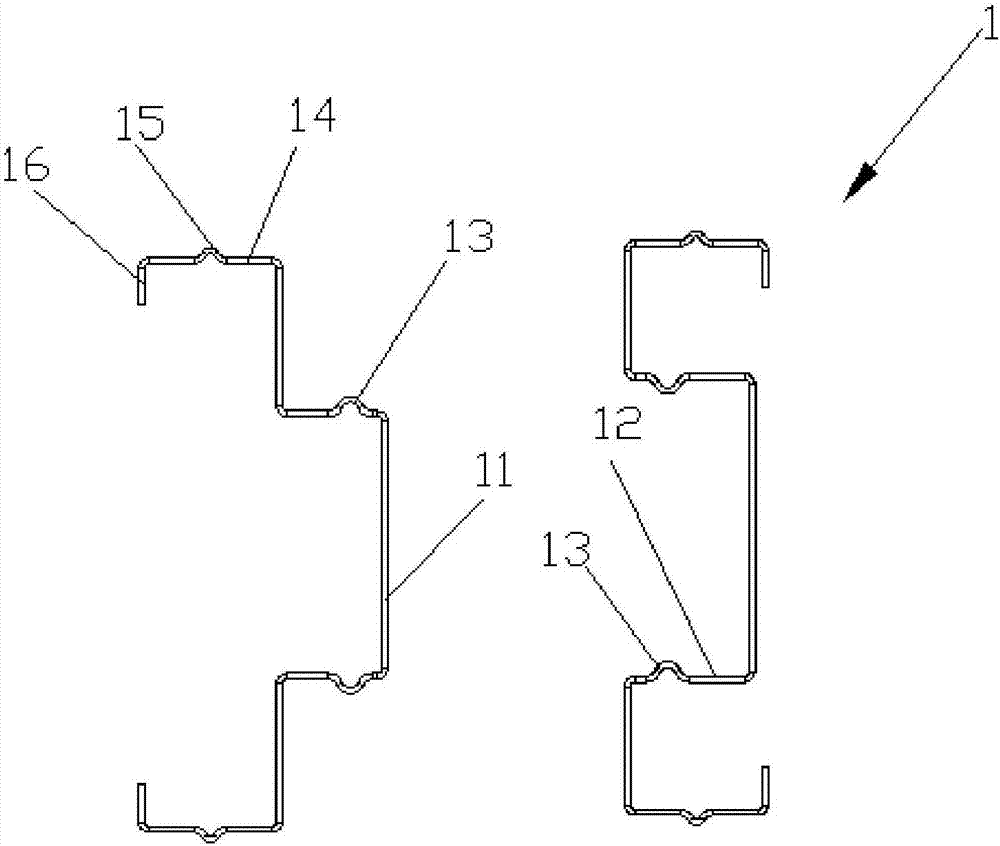

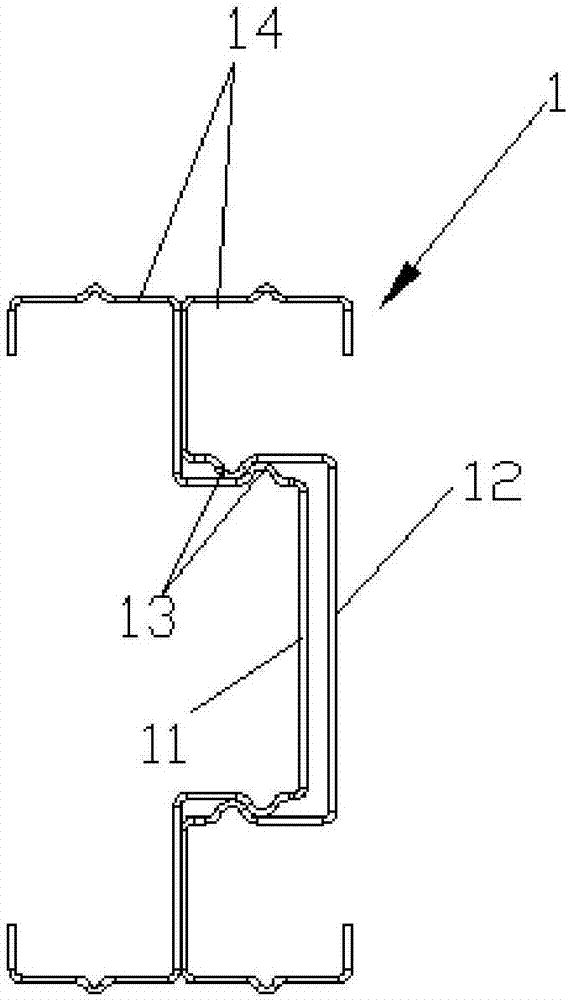

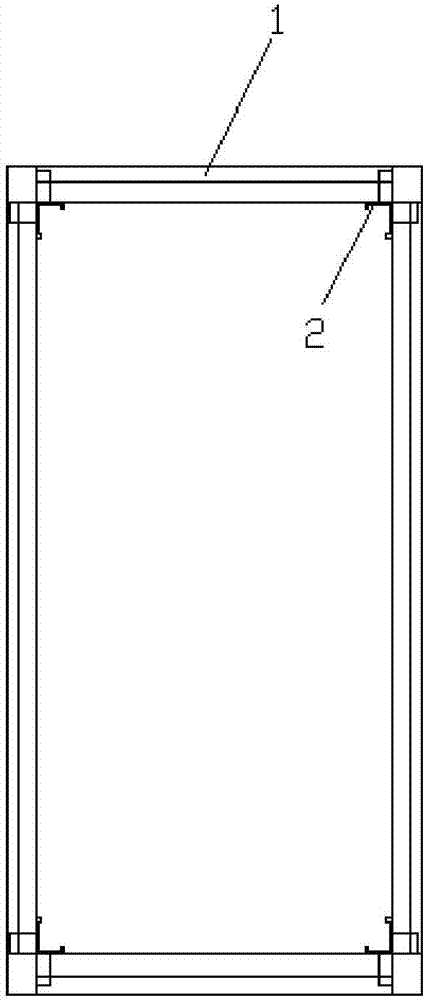

[0028] Such as Figure 1 to Figure 6 shown (except image 3Figures other than those shown are cross-sectional schematic diagrams), a wall panel frame, including a keel 1 forming a rectangular frame, and the keel 1 is provided with a protruding strip 11 or a groove 12 that can be matched to form a rectangular frame. The four keels 1 are composed of two keels 1 with one long and one short with protruding strips 11 and two with grooves 12. Extending along the length direction of the keel 1, the convex strip 11 and the groove 12 are provided with two symmetrical sides, the two sides are parallel to the central plane of the keel 1, and the convex strip 11 and the groove 12 are rectangular so that the convex strip 11 and the groove 12 are rectangular. The groove 12 has proper connection strength and can quickly realize insertion. The two ends of the width direction of the outer surface of the keel 1 are bent and extended in a direction away from the outer surface to form a mesh pa...

Embodiment 2

[0034] Such as Figure 7 As shown, the wall panel frame in this embodiment is the same as that in Embodiment 1 figure 1 The frame structure of the wall panel shown is basically the same, the difference is that the bending part 16 of the screen connecting surface 14 is provided with a third rib 17, the third rib 17 extends along the length direction of the keel 1, and the third rib 17 extends along the length direction of the keel 1. Rib 17 is also the convex rib of arc head, and the 3rd convex rib 17 connects iron 2 with interior angle (referring to image 3 ) pressure welding. The third rib 17 is convenient for pressure-welding connection between the inner angle connecting iron 2 and the keel 1, and the welding head presses the inner angle connecting iron 2 on the protruding third rib 17 for pressure welding, which is easy to realize production automation.

[0035] Such as Figure 8 As shown, the wall panel frame mold matched with the wall panel frame in this embodiment is...

Embodiment 3

[0037] Such as Figure 9 As shown, the wallboard frame and the wallboard frame mold in this embodiment are basically the same as those in Embodiment 2, the difference is that the two sides of the convex strip 11 or groove 12 set on the keel 1 and the central plane of the keel 1 are in a 5 -10 degree inclination, the top surface of the raised strip 11 is narrower than the root of the raised strip 11, because the raised strip 11 and the groove 12 are slightly isosceles trapezoidal, so that the butt joint installation of the two wallboards is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com