White emulsion preparation equipment for leather shoe manufacturing and producing process

A production process, white latex technology, applied in the direction of monocarboxylate copolymer adhesives, adhesive types, etc., can solve the problems that cannot be stirred and rotated to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

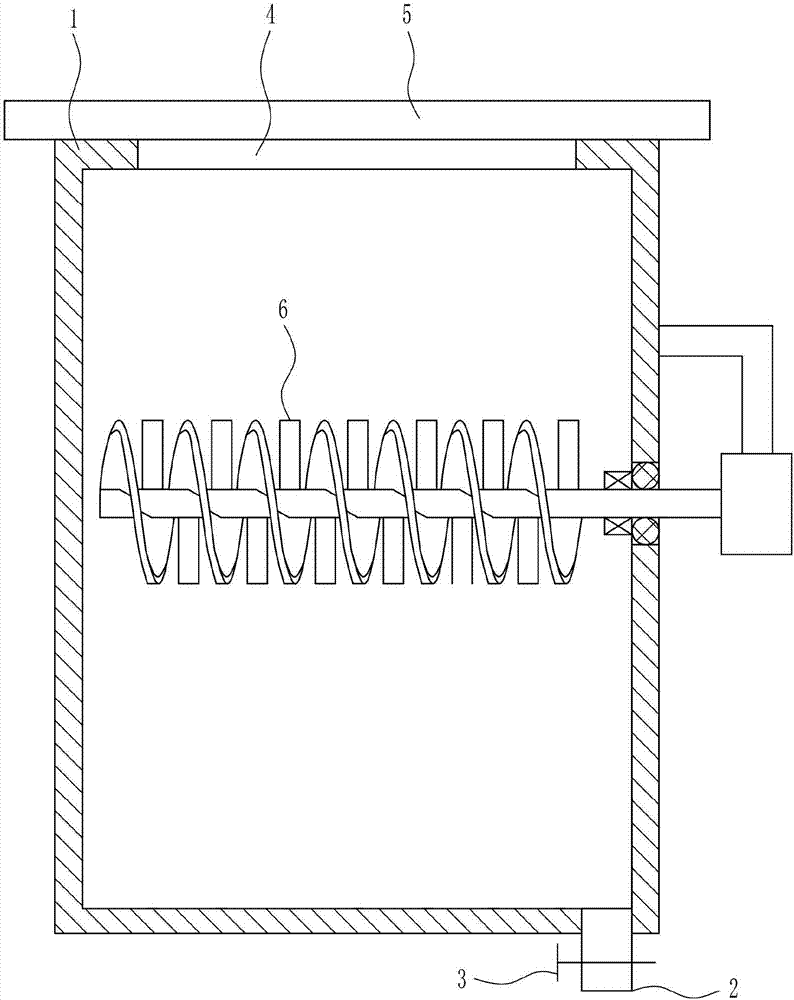

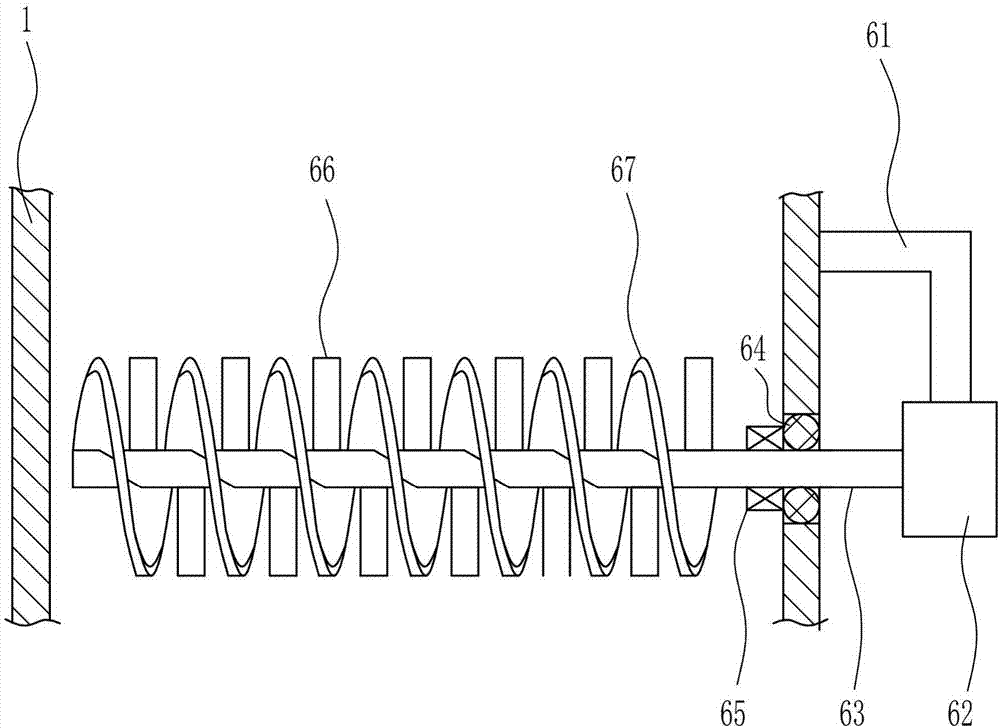

[0041] A kind of white latex preparation equipment for leather shoes manufacturing production process, such as Figure 1-7 As shown, it includes a mixing box 1, a discharge pipe 2, a valve 3, a capping mechanism 5 and a mixing mechanism 6. The bottom right side of the mixing box 1 is connected with a discharge pipe 2, and the discharge pipe 2 is connected with a valve 3. There is a first through hole 4 in the middle of the top wall of the box 1, a capping mechanism 5 is provided on the top of the mixing box 1, and a mixing mechanism 6 is provided in the middle of the mixing box 1.

Embodiment 2

[0043] A kind of white latex preparation equipment for leather shoes manufacturing production process, such as Figure 1-7 As shown, it includes a mixing box 1, a discharge pipe 2, a valve 3, a capping mechanism 5 and a mixing mechanism 6. The bottom right side of the mixing box 1 is connected with a discharge pipe 2, and the discharge pipe 2 is connected with a valve 3. There is a first through hole 4 in the middle of the top wall of the box 1, a capping mechanism 5 is provided on the top of the mixing box 1, and a mixing mechanism 6 is provided in the middle of the mixing box 1.

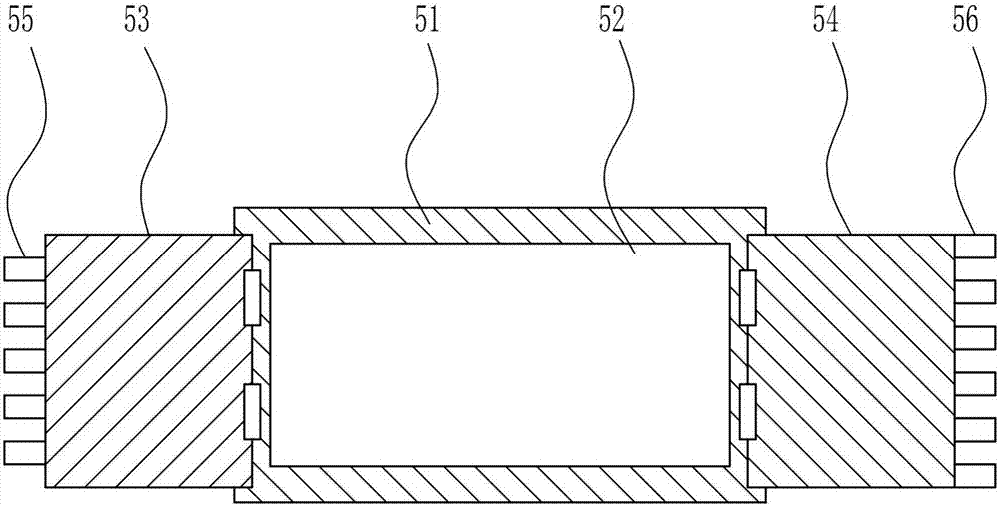

[0044] The closing mechanism 5 includes a baffle plate 51, a first cover plate 53, a second cover plate 54, a first block 55 and a second block 56, the top of the mixing box 1 is connected with a baffle plate 51, and the baffle plate 51 is provided with a The second through hole 52, the left and right sides of the baffle plate 51 are respectively connected with the first cover plate 53 and the seco...

Embodiment 3

[0046] A kind of white latex preparation equipment for leather shoes manufacturing production process, such as Figure 1-7 As shown, it includes a mixing box 1, a discharge pipe 2, a valve 3, a capping mechanism 5 and a mixing mechanism 6. The bottom right side of the mixing box 1 is connected with a discharge pipe 2, and the discharge pipe 2 is connected with a valve 3. There is a first through hole 4 in the middle of the top wall of the box 1, a capping mechanism 5 is provided on the top of the mixing box 1, and a mixing mechanism 6 is provided in the middle of the mixing box 1.

[0047] The closing mechanism 5 includes a baffle plate 51, a first cover plate 53, a second cover plate 54, a first block 55 and a second block 56, the top of the mixing box 1 is connected with a baffle plate 51, and the baffle plate 51 is provided with a The second through hole 52, the left and right sides of the baffle plate 51 are respectively connected with the first cover plate 53 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com