Method for manufacturing structural circuit integrated part based on fused deposition modelling technology

A technology of fused deposition forming and manufacturing method, applied in the field of 3D printing, can solve the problems of inability to process complex three-dimensional conductive channels from structural components, and achieve the effects of assembly-free, short production cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

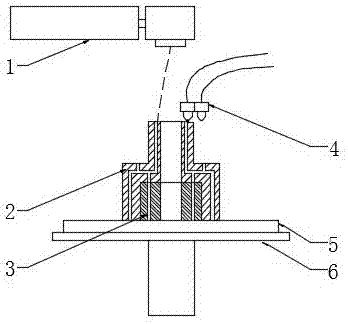

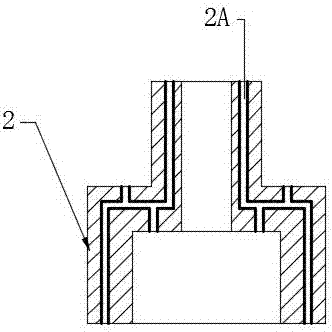

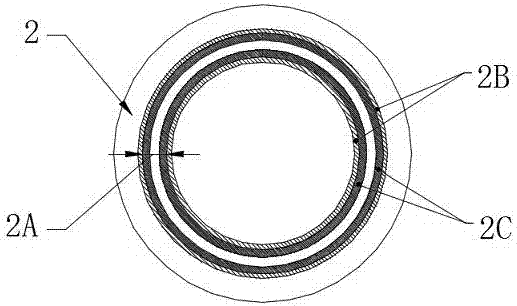

[0029] Such as Figure 1-3 shown.

[0030] A method for manufacturing a structure-circuit integrated component based on fused deposition modeling technology, specifically including the following steps:

[0031] (1) Use the 3D modeling software in the computer to establish the 3D model of the structural circuit integration components to be processed, such as figure 2 As shown, thin-walled circular tubes are used to replace the positions where conductive channels need to be arranged. The inner diameter of the thin-walled circular tubes is 0.5-2mm, and the wall thickness does not exceed 0.5mm. After the modeling is completed, it is saved as an STL file.

[0032] (2) Import the 3D model into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com