A kind of breathable composite film and preparation method thereof

A composite film and air permeability technology, applied in the field of breathable composite film and its preparation, can solve the problems affecting the air permeability uniformity of the film material, the small structure of the polypropylene hydrocarbon film, the harm to the human body and the environment, etc. Small size and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

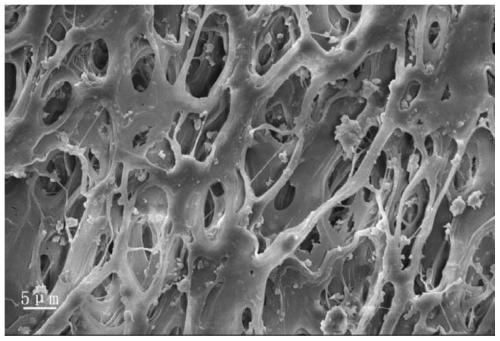

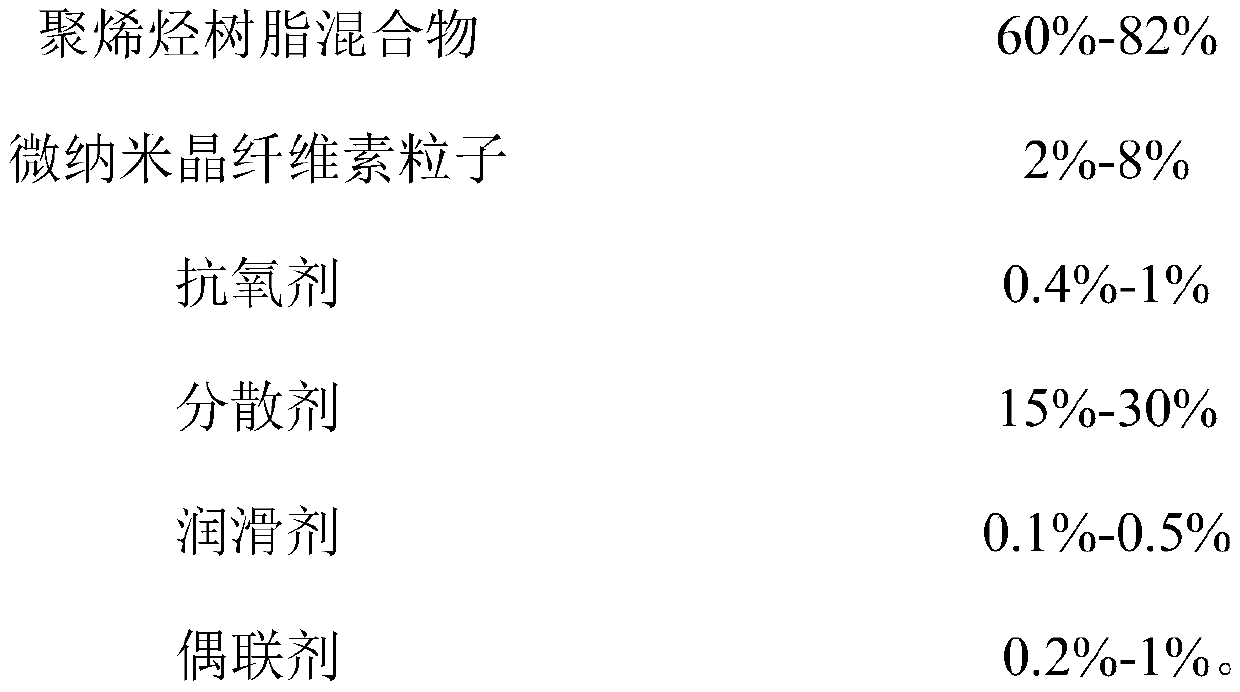

[0036] (1) 3.2kg concentration is 25g / L micronanocrystalline soybean seed coat cellulose aqueous dispersion liquid (particle diameter is 50nm-2 μ m) and 6g silane coupling agent KH580 in high-speed disperser (1000rpm), disperse again Add 300g dispersant polyethylene glycol PEG-200 and mix homogeneously in a high-speed mixer (1000rpm), and dry the mixture in an oven to obtain a pretreatment filler;

[0037] (2) 500g linear low density polyethylene (LLDPE), 100g ethylene-acrylate-glycidyl methacrylate (GMA), pretreatment filler, 4g phenolic 264 and phosphite BHT antioxidant, 10g lubricant Agent calcium stearate is premixed by high-speed mixer (1000rpm), gets premixed material;

[0038] (3) The premixed material is added to the feed port of the extruder through a metering feeder, melted and extruded by a co-rotating twin-screw extruder, cooled and granulated to obtain a finished gas permeable composite film composition. The aspect ratio of the twin-screw extruder used in the abo...

Embodiment 2

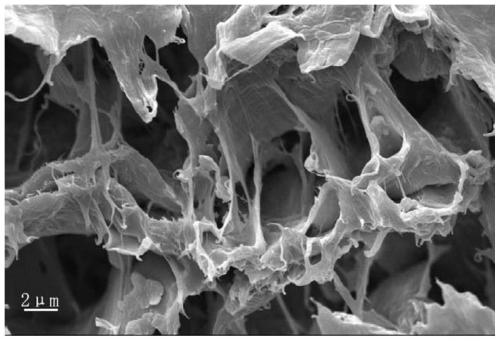

[0044] (1) Disperse 2.5kg of microcrystalline cotton cellulose aqueous dispersion (particle size: 500nm-10μm) with a concentration of 20g / L and 10g of silane coupling agent KH550 in a high-speed disperser (1000rpm), and then add the dispersant 225g Polyethylene Glycol PEG-400 is mixed in high-speed mixer (1000rpm), and its mixture is dried in baking oven and obtains pretreatment filler;

[0045] (2) 600g low-density polyethylene (LDPE), 100g ethylene-propylene copolymer (EPM), pretreatment filler, 4g hindered phenolic antioxidant 1010, 10g lubricant zinc stearate are passed through high-speed mixer (1200rpm) Perform premixing to obtain premixed materials;

[0046] (3) The premixed material is added to the feed port of the extruder through a metering feeder, melted and extruded by a co-rotating twin-screw extruder, cooled and granulated to obtain the air-permeable composite film composition pellets. The aspect ratio of the twin-screw extruder used in the above process is 40, t...

Embodiment 3

[0051] (1) Disperse 0.5 kg of microcrystalline hemp cellulose aqueous dispersion (with a particle size of 2 μm-50 μm) and 2 g of silane coupling agent KH590 in a high-speed disperser (1000 rpm) evenly, and then add the dispersant 150g polyethylene glycol PEG1000 is mixed homogeneously in high-speed mixer (1000rpm), and its mixture is dried in baking oven and obtains pretreatment filler;

[0052] (2) 700g high-density polyethylene (HDPE), 120g ethylene-octene copolymer (POE), pretreatment filler, 7g hindered phenolic antioxidant 1076 and 1g lubricant low-molecular PE wax are passed through a high-speed mixer (1200rpm ) for premixing;

[0053] (3) The premixed material is added to the feed port of the extruder through a metering feeder, melted and extruded by a co-rotating twin-screw extruder, cooled and granulated to obtain a finished gas permeable composite film composition. The aspect ratio of the twin-screw extruder used in the above processing process is 50, the screw spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com