A lignite boiling dehydration device and method

A dehydration device, lignite technology, applied in solid fuel, petroleum industry, fuel and other directions, can solve the problems of complex structure of drying equipment, large steam consumption, spontaneous combustion and explosion of lignite, etc., to improve heat transfer efficiency and heating uniformity, device The structure and process are simple, and the effect of eliminating the discharge of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

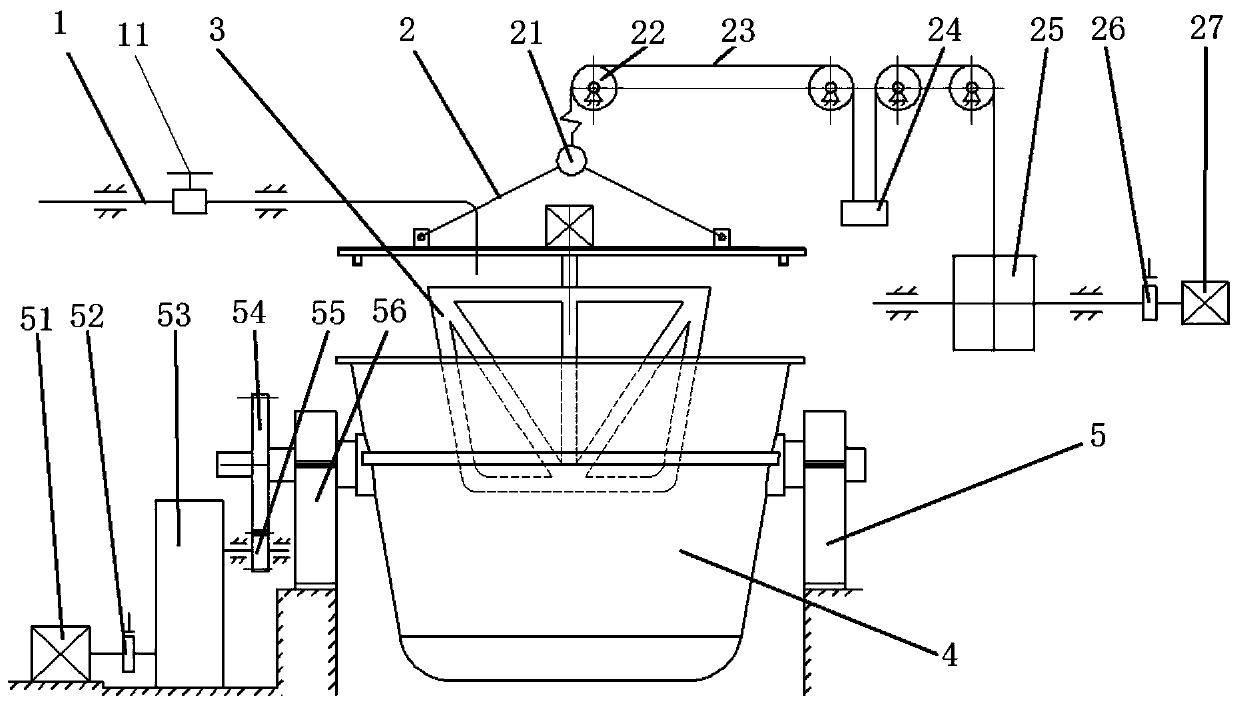

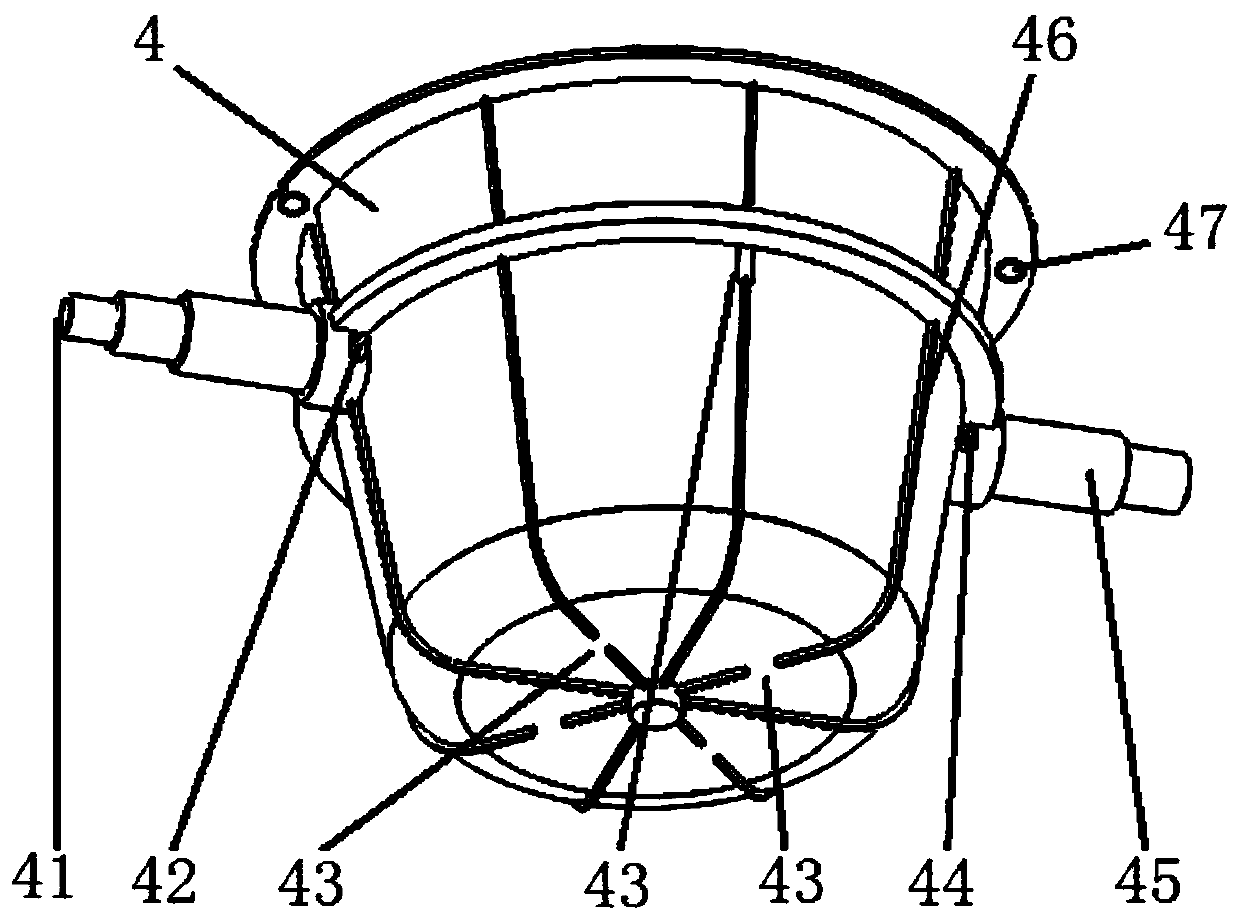

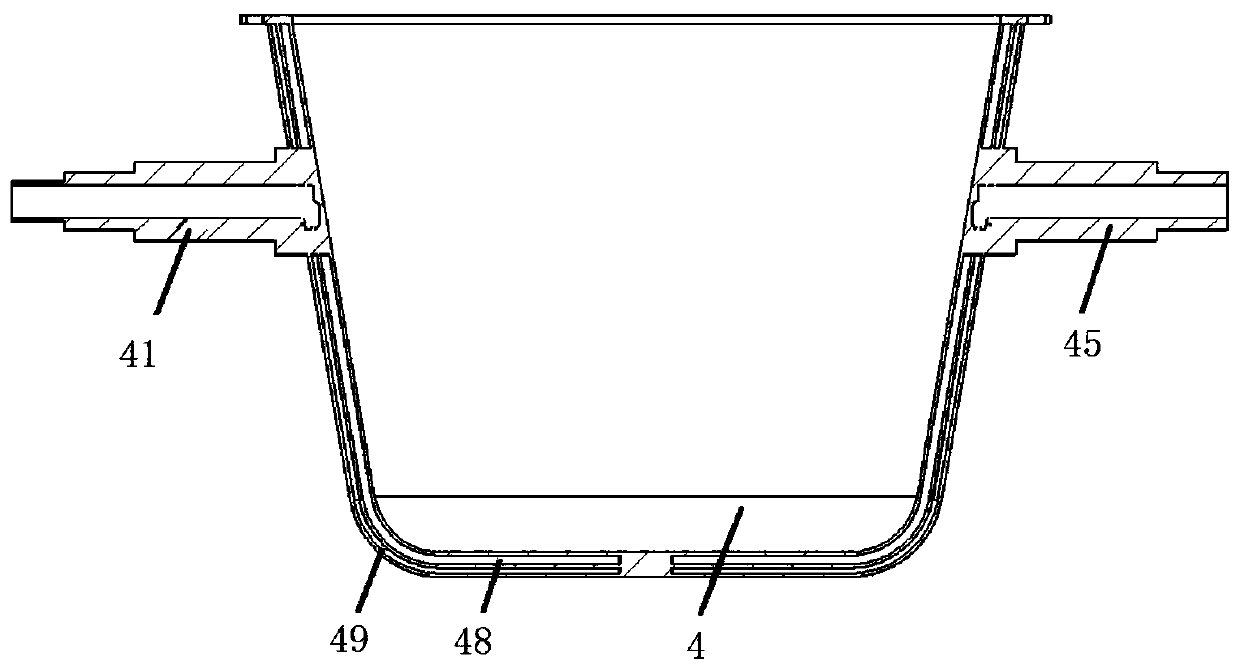

[0030] Such as figure 1 As shown, a lignite boiling dehydration device according to the present invention includes a sandwich pot 4, a water delivery pipeline 1, a stirring device 3, a tilting device and a pulley device 2; the sandwich pot 4 is provided with a steam interlayer 48, and the sandwich pot 4 Hollow trunnions 41, 45 are provided on both sides to communicate with the steam interlayer 48, and the hollow trunnions 41, 45 on both sides are used as steam inlets and steam outlets respectively to communicate with external superheated steam pipes; Driven by the pulley device 2 to realize the lifting action; the water outlet of the input water pipeline 1 is set above the sandwich pot 4, and the water volume control valve 11 is set on the water delivery pipeline 1; the sandwich pot 4 is erected on the tilting device 5 and can be driven by it Til...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com