High-tenacity caulking water stop belt for channel structure and construction method of high-tenacity caulking water stop belt

A technology of waterstop and high toughness, which is applied in the field of caulking waterstop, which can solve the problems of loss of elasticity and reduction of caulking waterstop effect, etc., achieve long-term waterstop effect, low cost, and easy to obtain local materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

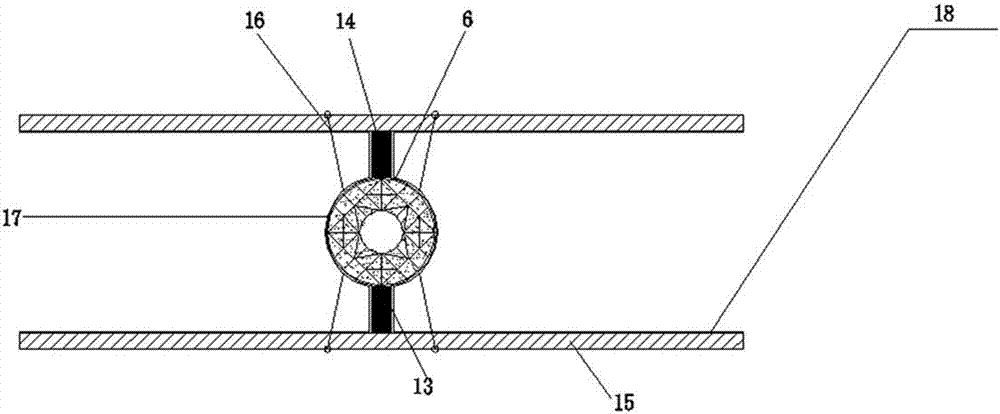

[0033] Such as Figure 10 As shown, a high-toughness caulking waterstop for channel structures described in this embodiment includes a hard permeable pipe 9, the hard permeable pipe is a hollow pipe, and the outer wall of the hard permeable pipe 9 is sequentially provided with filter paper 8 And spray quick-setting rubber 6. During the transportation of this product, a layer of waterproof packaging film can be installed on the outside. The waterproof packaging film is a kind of packaging paper lined with high-density polyethylene film coating, which has good waterproofness and toughness, and plays the role of moisture-proof . The top of the hard permeable pipe 9 is provided with a rubber block 12, which is easy to open when overhauling and injecting water to the inside. The spraying quick-setting rubber is a two-component spraying quick-setting rubber material, which forms a dense, uniform, high-elasticity and high-toughness rubber with an average thickness of 2mm to 5mm wit...

Embodiment 2

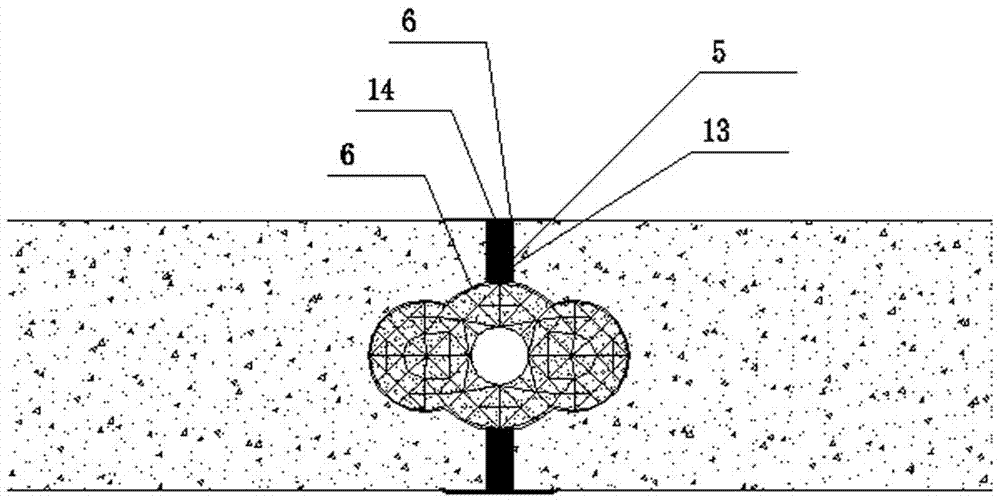

[0045] Such as figure 2 As shown, the cross-section of a high-toughness caulking waterstop for channel structures described in this embodiment is composed of a ring and two semicircles intersecting, the two semicircles are located on both sides of the ring, and the rest Structure and construction method are the same as embodiment 1.

Embodiment 3

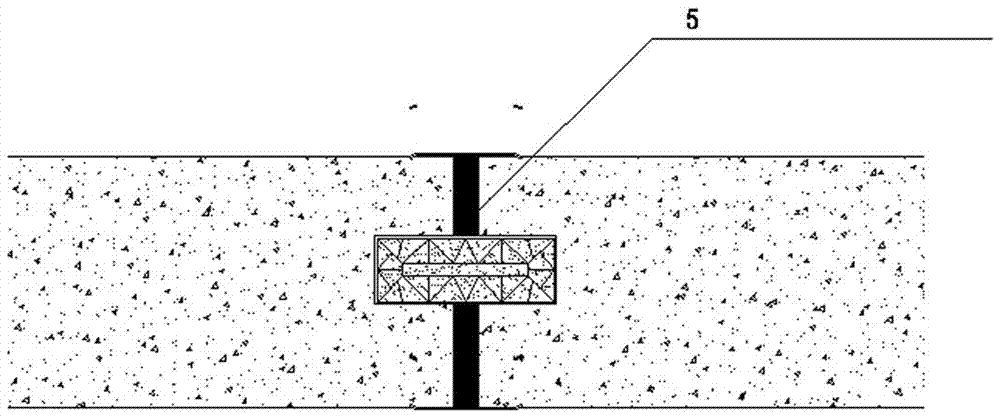

[0047] Such as image 3 As shown, the cross-section of a high-toughness caulking waterstop for channel structures described in this embodiment is a rectangular ring, and the rest of the structure and construction method are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com